This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

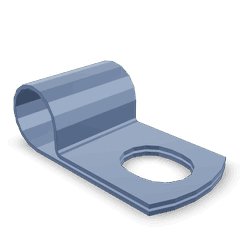

The Cummins 3627412 Clip is a specialized component designed for use in heavy-duty truck operations. This clip serves a specific function within the truck’s system, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and role is fundamental for maintaining and optimizing truck performance.

Purpose and Function

The Cummins 3627412 Clip plays a role in securing various components within the truck’s system. It is commonly used to hold hoses, wires, or other parts in place, ensuring they remain properly positioned and do not interfere with other systems. This clip contributes to the overall functionality of the vehicle by maintaining the integrity of the connections and reducing the risk of damage or disconnection during operation 1.

Key Features

The Cummins 3627412 Clip is characterized by its robust design and durable materials. It is typically made from high-strength polymers or metals, ensuring it can withstand the rigors of heavy-duty use. The clip features a secure locking mechanism that provides a firm hold on the components it is designed to secure. Its design allows for easy installation and removal, making it a practical choice for both original equipment manufacturers and aftermarket applications 2.

Benefits

Using the Cummins 3627412 Clip offers several advantages. Its durable construction ensures long-lasting performance, reducing the need for frequent replacements. The ease of installation simplifies maintenance procedures, allowing for quick and efficient component securing. Additionally, the clip’s reliable hold enhances the overall performance and safety of the truck by preventing component displacement or damage 3.

Installation Process

Installing the Cummins 3627412 Clip involves several steps to ensure proper placement and function. Begin by identifying the location where the clip is needed. Use the appropriate tools, such as pliers or a clip installation tool, to position the clip around the component. Ensure the clip is fully engaged and securely locked in place. Verify that the component is held firmly without any risk of movement or disconnection.

Common Issues and Troubleshooting

Common issues with the Cummins 3627412 Clip may include improper installation, which can lead to a loose hold on the component. To address this, ensure the clip is correctly positioned and fully engaged. If the clip becomes damaged or worn, it should be replaced to maintain secure component placement. Regular inspection can help identify any issues early, allowing for timely corrections.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3627412 Clip, regular maintenance is recommended. Inspect the clip during routine maintenance checks to ensure it remains securely in place and shows no signs of wear or damage. Clean the clip and surrounding areas to prevent buildup that could affect its function. Replace the clip if any damage is detected to maintain secure component placement.

Manufacturer Information

Cummins is a renowned manufacturer with a long-standing reputation in the automotive and heavy-duty truck industry. The company is known for producing high-quality components that enhance the performance and reliability of vehicles. Cummins’ commitment to innovation and excellence ensures that their products, including the 3627412 Clip, meet the demanding requirements of heavy-duty applications.

Cummins Engine Part 3627412: Clip Compatibility

The Cummins part 3627412, a Clip, is designed to fit a variety of Cummins engines, ensuring compatibility across multiple models. This clip is an essential component in maintaining the integrity and functionality of the engine systems it is used in.

Compatible Engines

- 6B5.9

- K19

- K38

- K50

- KTA38GC CM558

- N14 CELECT PLUS

- QSK19 CM2350 K105

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

- QSK45 CM500

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

- QSK60 CM500

- QSK60 CM850 MCRS

- QSK60G

- QSK78 CM500

- QSK95 CM2350 K111

Grouping of Compatible Engines

The clip is engineered to fit within the following groups of engines:

-

QSK Series:

- QSK19 CM2350 K105

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

- QSK45 CM500

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

- QSK60 CM500

- QSK60 CM850 MCRS

- QSK60G

- QSK78 CM500

- QSK95 CM2350 K111

-

Other Cummins Engines:

- 6B5.9

- K19

- K38

- K50

- KTA38GC CM558

- N14 CELECT PLUS

This clip is integral in securing various parts within the engine assembly, ensuring that components remain in place and function correctly. Its design allows for easy installation and removal, facilitating maintenance and repair processes.

Role of Part 3627412 Clip in Engine Systems

Part 3627412 Clip is integral to the assembly and functionality of various engine components. It ensures secure connections and proper alignment, facilitating efficient operation of the engine system.

Accessories

The clip is used in the assembly of engine accessories, ensuring they are firmly attached and correctly positioned. This is important for the accessories to function as intended without causing undue stress on the engine components.

Electric Starting

In the electric starting system, the clip secures wiring and connections, ensuring reliable electrical conductivity. This is essential for the consistent operation of the starter motor and related components.

By-Pass Oil Filter Mounting

For the by-pass oil filter, the clip holds the mounting components in place, ensuring the filter is correctly aligned and sealed. This helps maintain optimal oil flow and filtration, protecting the engine from contaminants.

Camshaft and Camshaft Gear

The clip plays a role in securing the camshaft and its gear, ensuring they remain in proper alignment. This is vital for the precise timing of valve operations, which directly affects engine performance and efficiency.

Sensor Harness Mounting

In sensor harness mounting, the clip ensures that sensors are securely attached and correctly positioned. Accurate sensor readings are crucial for the engine control module to make appropriate adjustments to engine operations.

Connection and Water Outlet

For water outlet connections, the clip ensures a tight seal, preventing coolant leaks. This maintains the integrity of the cooling system, which is essential for regulating engine temperature.

Connection Mounting Parts for Water

Similarly, for connection mounting parts related to water systems, the clip ensures secure and leak-free connections. This is important for maintaining consistent coolant flow and pressure.

Coolant Pressure Kit

In the coolant pressure kit, the clip secures components that maintain pressure within the cooling system. This helps prevent coolant loss and ensures efficient heat dissipation from the engine.

Corrosion Resistor Head

The clip is used in the assembly of the corrosion resistor head, ensuring it is firmly attached and functions correctly. This component helps protect the engine from corrosion, extending its lifespan.

Fuel Filter

For the fuel filter, the clip secures the filter in place, ensuring it is correctly aligned within the fuel system. This is important for maintaining clean fuel delivery to the engine, which affects combustion efficiency.

Fuel Left Bank Manifold

In the fuel left bank manifold, the clip ensures secure connections, maintaining the integrity of the fuel delivery system. This is essential for balanced fuel distribution to the engine cylinders.

Fuel Tubing

The clip is used to secure fuel tubing, ensuring there are no leaks or disconnections. This maintains consistent fuel pressure and flow, which is critical for engine performance.

Heat Exchanger

For the heat exchanger, the clip ensures that all connections are secure and leak-free. This is important for efficient heat transfer, which helps regulate engine temperature.

Left Bank Oil Control Connection

In the left bank oil control connection, the clip ensures that oil pathways are correctly aligned and sealed. This is vital for maintaining proper oil pressure and flow within the engine.

Manifold and Air Intake

The clip secures components in the manifold and air intake system, ensuring they are correctly positioned. This is important for maintaining optimal air-fuel mixture and engine performance.

Engine Control Module

For the engine control module, the clip ensures that all electrical connections are secure. This is essential for the module to receive accurate sensor data and send appropriate signals to engine components.

Electronic Engine Monitor

In the electronic engine monitor, the clip secures components that monitor engine performance. This ensures the monitor can accurately track and report engine conditions.

Oil Control Valve

The clip is used to secure the oil control valve, ensuring it is correctly positioned within the oil system. This is important for regulating oil flow and pressure, which affects engine lubrication.

Oil Right Bank Supply Connection

For the oil right bank supply connection, the clip ensures that oil pathways are correctly aligned and sealed. This is vital for maintaining proper oil supply to the right bank of the engine.

Oil Transfer Right Bank Connection

In the oil transfer right bank connection, the clip ensures secure and leak-free connections. This maintains consistent oil flow and pressure, which is critical for engine lubrication.

Plate Mounting

The clip is used in plate mounting to ensure components are firmly attached and correctly aligned. This is important for the structural integrity and functionality of various engine systems.

Oxygen Sensor

For the oxygen sensor, the clip ensures it is securely mounted and correctly positioned. Accurate oxygen readings are essential for the engine control module to adjust fuel delivery and combustion efficiency.

Step White Smoke Kit

In the step white smoke kit, the clip secures components that help diagnose and address issues related to white smoke emissions. This is important for maintaining engine health and performance.

Valve Mounting

The clip secures valve mounting components, ensuring they are firmly attached and correctly aligned. This is vital for the precise operation of engine valves, which directly affects combustion efficiency.

Vent Lines

For vent lines, the clip ensures secure connections, preventing leaks and maintaining the integrity of the venting system. This is important for regulating pressure and preventing build-up within the engine compartment.

Heat Exchanger

Finally, the clip is used in the heat exchanger to ensure all connections are secure and leak-free. This is essential for efficient heat transfer, which helps regulate engine temperature and maintain optimal performance.

Conclusion

The Cummins 3627412 Clip is a critical component in heavy-duty truck operations, ensuring the secure placement and functionality of various engine components. Its robust design, ease of installation, and reliable performance make it an essential part for maintaining the efficiency and reliability of heavy-duty vehicles. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.