This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

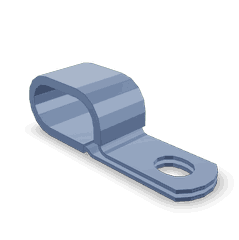

The Cummins 3629516 Clip is a component designed for use in commercial trucks, playing a role in ensuring the proper operation and maintenance of these vehicles. Cummins Inc., a well-established manufacturer in the automotive industry, produces this clip as part of their extensive range of truck components. Understanding the function and significance of this Cummins part is important for maintaining the efficiency and reliability of commercial trucks.

Purpose and Function

This part serves a specific role in the operation of a truck by securing components in place, thereby maintaining structural integrity and ensuring proper alignment. This clip is integral to the truck’s system, as it helps in the secure attachment of various parts, which is vital for the overall performance and safety of the vehicle.

Key Features

The 3629516 Clip is characterized by its robust design and material composition, which includes high-quality metals that provide durability and resistance to wear 1. Its design is tailored to fit specific applications, ensuring a secure and reliable connection. The clip’s unique characteristics, such as its corrosion-resistant properties, enhance its performance and longevity in various operating conditions.

Benefits

The use of the 3629516 Clip offers several benefits, including improved reliability and ease of installation 2. These advantages contribute to the overall performance of the truck, providing truck operators and fleet managers with a component that ensures consistent operation and reduces the need for frequent maintenance. The clip’s design also allows for straightforward installation, minimizing downtime during repairs or component replacements.

Installation Process

Installing the Cummins 3629516 Clip requires following a step-by-step process to ensure proper fitting and function. It is recommended to use specific tools and equipment for installation to achieve the best results. Best practices include verifying the correct orientation of the clip and ensuring it is securely fastened to avoid any issues during operation.

Maintenance and Troubleshooting

To ensure the longevity and optimal performance of the 3629516 Clip, regular maintenance is recommended. This includes periodic inspections to check for signs of wear or damage. Common issues may involve misalignment or corrosion, which can be addressed through proper troubleshooting steps. Replacing the clip when necessary is also important to maintain the structural integrity of the truck.

Safety Considerations

When working with the 3629516 Clip, it is important to follow safety practices to prevent injuries or component damage. This includes using the correct tools and adhering to manufacturer guidelines. Ensuring a safe working environment and proper handling of the clip are crucial for the safety of personnel and the reliability of the truck’s components.

Cummins Overview

Cummins Inc. has a long-standing history in the automotive and trucking industries, known for their commitment to quality and innovation in manufacturing truck components. Their extensive range of products, including the 3629516 Clip, reflects their dedication to providing reliable and high-performance solutions for commercial vehicles. Cummins’ contributions have significantly impacted the efficiency and reliability of trucks worldwide.

Compatibility with Engine Models

The 3629516 Clip is designed to integrate seamlessly with a variety of Cummins engine models. This clip is a critical component in ensuring the proper functioning and longevity of the engine by securing various parts in place. Below is a detailed overview of its compatibility with specific engine models:

K38 and K50 Engines

The Clip 3629516 is specifically engineered to fit the K38 and K50 engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The clip ensures that internal components remain securely fastened, preventing any unwanted movement that could lead to mechanical failure.

QSK38 CM2150 MCRS and QSK60 CM500

For the QSK38 CM2150 MCRS and QSK60 CM500 engines, the Clip 3629516 plays a crucial role in maintaining the integrity of the engine’s internal structure. These engines are part of Cummins’ QSK series, which is renowned for its high power output and efficiency. The clip’s design allows it to fit perfectly within the engine’s architecture, providing the necessary support to various components.

QSK60 CM850 MCRS and QSK60G

The QSK60 CM850 MCRS and QSK60G engines also benefit from the Clip 3629516. These engines are designed for applications requiring high power and durability. The clip ensures that all parts remain in their designated positions, contributing to the engine’s overall performance and longevity. Its precision fit is particularly important in these high-performance engines, where even minor misalignments can lead to significant issues.

Role of Part 3629516 Clip in Engine Systems

The 3629516 Clip is instrumental in ensuring the secure and efficient operation of various engine components. It plays a significant role in the integration and functionality of the following systems:

Accessories

The Clip is used to fasten accessories to the engine, ensuring they remain in place during operation. This includes components like the electric starting system, which relies on secure mounting to function correctly.

Aftercooler Core and Plumbing

In aftercooler systems, the Clip is employed to hold the aftercooler core in position and to secure the aftercooler plumbing. This ensures that the cooling process is efficient and that there are no leaks in the system.

Base Parts and Performance Components

For base parts and performance-enhancing components, the Clip provides the necessary stability. It ensures that these parts are correctly aligned and do not shift during engine operation, which is essential for maintaining performance standards.

Camshaft and Gear Connection

The Clip is vital in securing the camshaft and gear connection, particularly in the right and left bank steps. This ensures smooth operation and prevents any misalignment that could lead to engine inefficiencies.

Fuel System Connections

In the fuel system, the Clip is used to secure connections in the left and right bank fuel blocks, as well as the fuel manifolds. This is important for maintaining the integrity of the fuel delivery system and preventing leaks.

Drive and Fan Assembly

For the drive and fan assembly, the Clip ensures that all components are tightly secured. This is essential for the efficient operation of the fan, which plays a key role in engine cooling.

Harness and Wiring

The Clip is also used in securing harnesses and wiring throughout the engine. This ensures that electrical connections remain intact and that there is no risk of short circuits or other electrical failures.

Oil Control Valve and Corrosion Resistance

In systems involving the oil control valve, the Clip helps in maintaining the valve’s position and ensuring it operates within specified parameters. Additionally, in areas prone to corrosion, the Clip aids in securing components, helping to prevent corrosion-related failures.

Fuel Plumbing and Injectors

Finally, in fuel plumbing and injector systems, the Clip ensures that all connections are secure. This is crucial for maintaining the precision of fuel delivery and ensuring that injectors operate efficiently.

Conclusion

The Cummins 3629516 Clip is a vital component in the maintenance and operation of commercial trucks. Its robust design, ease of installation, and compatibility with various Cummins engine models make it an essential part for ensuring the efficiency and reliability of these vehicles. Regular maintenance and proper installation are key to maximizing the benefits of this part, contributing to the overall performance and safety of the truck.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.