This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Fastening Clip 3895612 is a component manufactured by Cummins, a prominent entity in the commercial truck industry. This part is integral to the assembly and operation of commercial trucks, contributing to the overall efficiency and safety of these vehicles.

Purpose and Function

The Fastening Clip 3895612 serves to secure various components within a truck’s assembly. Its role is to ensure that parts remain firmly in place, which is vital for maintaining stability and safety during operation. By securing components, it helps prevent movement that could lead to wear, damage, or failure of truck parts 1.

Key Features

The Fastening Clip 3895612 is designed with specific elements that enhance its performance and durability. It is constructed from high-quality materials that can withstand the rigors of commercial truck environments. The clip’s design includes features that allow for a snug fit, ensuring that components are held securely in place. Additionally, it is engineered to resist corrosion and other forms of degradation, which contributes to its longevity 2.

Benefits

Using the Fastening Clip 3895612 offers several advantages. It provides improved security for components, reducing the risk of parts becoming dislodged during operation. The clip is designed for ease of installation, which can save time during truck maintenance or assembly. Furthermore, its durable construction ensures long-term reliability, minimizing the need for frequent replacements 3.

Installation Process

To install the Fastening Clip 3895612, begin by identifying the components that require securing. Position the clip over the designated area, ensuring it aligns correctly with the components. Apply gentle pressure to engage the clip, making sure it is firmly in place. It is important to follow the manufacturer’s guidelines to avoid common pitfalls such as over-tightening, which could damage the clip or the components it secures 4.

Maintenance and Troubleshooting

Regular maintenance of the Fastening Clip 3895612 is key to ensuring optimal performance. Inspect the clip periodically for signs of wear or damage. If the clip appears loose or damaged, it should be replaced to maintain component security. Troubleshooting common issues may involve checking for proper alignment and ensuring that the clip is not subjected to excessive force during operation.

Compatibility and Applications

The Fastening Clip 3895612 is designed for use in a variety of truck models and applications. Its versatility makes it suitable for securing components in different parts of the truck, contributing to the overall integrity of the vehicle’s assembly.

Safety Considerations

When working with the Fastening Clip 3895612, it is important to adhere to safety protocols. This includes wearing appropriate personal protective equipment and ensuring that the work area is free from hazards. Proper handling and installation of the clip are crucial to avoid injury and ensure the clip functions as intended.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes a variety of components and systems that contribute to the performance and reliability of commercial vehicles.

Fastening Clip 3895612 Compatibility with Cummins Engines

The Fastening Clip part number 3895612, manufactured by Cummins, is designed to fit a variety of Cummins engines. This clip is essential for securing components and ensuring the integrity of the engine’s assembly. Below is a detailed breakdown of the engines with which this part is compatible:

ISX Series Engines

- ISX CM871

- ISX12 CM2350 X102

- ISX12 G CM2180 EJ

- ISX12/ISX11.9 CM2250

- ISX15 CM2250

- ISX15 CM2250 SN

- ISX15 CM2350 X101

QSX Series Engines

- QSX11.9 CM2250 ECF

- QSX15 CM2250

- QSX15 CM2250 ECF

- QSX15 CM2350 X105

QSK Series Engines

- QSK19 CM2350 K114

- QSK45 CM500

- QSK60 CM500

- QSK60 CM850 MCRS

- QSK60G

Other Cummins Engines

- ISM CM876

- L10 GAS

- L10 MECHANICAL

- M11 CELECT PLUS

- M11 MECHANICAL

- QSM11 CM570

- QSV91-G4 CM558/CM700 V102

- VTA903 CM2250 V105

- X15 CM2350 X116B

This fastening clip is engineered to meet the specific requirements of these engines, ensuring a secure fit and reliable performance. It is crucial for maintaining the structural integrity of the engine components and preventing any potential loosening or failure during operation.

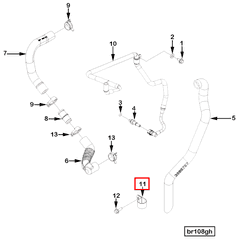

Role of Fastening Clip 3895612 in Engine Systems

The Fastening Clip 3895612 is integral to the secure assembly and operation of various engine components. Its application ensures that parts are held firmly in place, contributing to the overall efficiency and reliability of the engine system.

Air Compressor Kit

In the air compressor kit, the fastening clip is used to secure the compressor to its mounting points. This ensures that the compressor remains stable during operation, reducing vibrations and potential wear on the unit.

Compressor Air Inlet Arrangement

For the compressor air inlet arrangement, the fastening clip plays a role in securing the inlet components. This is vital for maintaining the integrity of the air pathway, ensuring that the compressor receives a consistent airflow, which is essential for optimal performance.

Crankcase Breather and Plumbing

The fastening clip is employed in the crankcase breather system to secure breather components and plumbing. This helps in maintaining the proper ventilation of the crankcase, which is necessary for the efficient operation of the engine.

Full Flow Oil Filter

In the context of the full flow oil filter, the fastening clip is used to secure the filter housing. This ensures that the filter remains in place, allowing for effective filtration of the engine oil and contributing to the longevity of engine components.

Electronic Control Module Wiring Harness

The fastening clip is utilized in the electronic control module (ECM) wiring harness to secure wires and connectors. This is important for maintaining the integrity of the electrical connections, ensuring reliable communication between the ECM and various engine sensors and actuators.

Engine and Left Bank Brace and Harnesses

For the engine and left bank brace and harnesses, the fastening clip is used to secure harnesses and braces. This contributes to the structural stability of the engine, reducing the risk of component displacement or damage during operation.

Engine Control Module and Mounting

In the engine control module and its mounting, the fastening clip ensures that the module is securely attached to its designated location. This is important for the module’s protection and for maintaining a stable electrical connection.

Engine Monitor and Plumbing

The fastening clip is used in the engine monitor and its associated plumbing to secure sensors and pipes. This ensures accurate monitoring of engine parameters and maintains the integrity of the fluid pathways.

Turbocharger and Plumbing

For the turbocharger and its plumbing, the fastening clip secures the turbocharger to its mounting points and ensures that the plumbing is held in place. This is essential for the efficient operation of the turbocharger and the maintenance of boost pressure.

CRC Breather and PRS Regulator

In the CRC breather and PRS regulator systems, the fastening clip is used to secure components and plumbing. This ensures the proper functioning of these systems, which are important for maintaining engine performance and emissions control.

Primer and Engine Lubricating Recirculation

The fastening clip is utilized in the primer and engine lubricating recirculation systems to secure components. This ensures that these systems operate efficiently, contributing to the proper lubrication and priming of the engine.

Exhaust and Tube Brace

Finally, in the exhaust system and tube brace, the fastening clip is used to secure exhaust components and braces. This ensures that the exhaust system remains intact, contributing to the efficient expulsion of exhaust gases and the structural integrity of the system.

Conclusion

The Fastening Clip 3895612 by Cummins is a critical component in the assembly and operation of commercial trucks and engines. Its role in securing various components ensures the stability, safety, and efficiency of these vehicles. The clip’s durable construction, ease of installation, and compatibility with a wide range of Cummins engines make it a valuable asset in the maintenance and reliability of commercial truck fleets.

-

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩ -

Hilgers, M. (2023). Chassis and Axles. Springer Vieweg.

↩ -

Hilgers, M. (2023). Electrical Systems and Mechatronics, Second Edition. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). ISB, ISC, ISL, ISBe, ISDe, and QSB3.3 CM2150 Electronic Control System. Troubleshooting and Repair Manual. Bulletin Number 4021570.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.