This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

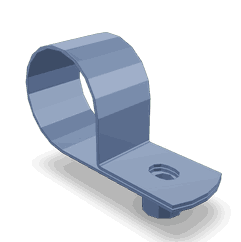

The Cummins 3921815 Clip is a component designed for use in commercial trucks, playing a role in the assembly and maintenance of various truck components. Cummins, a well-established manufacturer in the automotive industry, is known for producing reliable and high-quality parts that contribute to the efficient operation of commercial vehicles. This clip is one such part, integral to the functionality and durability of truck systems 1.

Purpose and Function

The 3921815 Clip serves multiple functions within the operation of a truck. It aids in the secure attachment and alignment of components, ensuring that parts are correctly positioned and maintained. This clip is often used in environments that demand high durability and resistance to wear, such as in heavy-duty truck applications where components are subjected to significant stress and varying conditions 2.

Key Features

The design of the 3921815 Clip incorporates specific material characteristics that enhance its performance and longevity. Made from durable materials, the clip is engineered to withstand the rigors of commercial truck use. Cummins employs stringent manufacturing processes and quality control measures to ensure that each clip meets the high standards required for automotive applications 3.

Benefits

Using the 3921815 Clip in truck maintenance and assembly offers several advantages. It contributes to improved efficiency by facilitating easier and more secure component attachment. Additionally, the clip enhances the reliability and safety of truck operations by ensuring that parts remain correctly aligned and secured. Its design also provides cost-effectiveness over time, reducing the need for frequent replacements and maintenance 4.

Installation and Usage

Proper installation of the 3921815 Clip involves following a step-by-step process to ensure it is correctly positioned and secured. Best practices for using the clip include verifying that all components are clean and free of debris before installation. Specific tools or equipment may be required to install the clip, depending on the application 5.

Troubleshooting and Maintenance

Common issues with the 3921815 Clip may include misalignment or wear over time. Troubleshooting steps involve checking for proper installation and ensuring that the clip is not damaged. Regular maintenance, such as inspecting for signs of wear or damage, can help ensure the longevity and optimal performance of the clip. Replacement should be considered if the clip shows significant signs of wear or if it no longer secures components effectively 6.

Safety Considerations

When installing or maintaining the 3921815 Clip, it is important to follow safety protocols to prevent injuries or accidents. Potential hazards associated with improper use or installation include component failure or injury from misaligned parts. The clip meets specific safety certifications and standards, ensuring it is safe for use in commercial truck applications 7.

Cummins Overview

Cummins is a renowned company in the automotive industry, with a history of innovation and quality in manufacturing. The company is known for its reputation in producing reliable and high-performance parts for commercial trucks. Cummins’ contributions to the sector include a wide range of products that enhance the efficiency, reliability, and safety of commercial vehicles 8.

Cummins Engine Compatibility with Part 3921815

The Clip part 3921815, manufactured by Cummins, is designed to fit a variety of their engine models. This clip is integral to the engine’s operation, ensuring proper assembly and function of various components. Below is a detailed breakdown of the engines that are compatible with this part:

Compatible Engines

- 4B3.9

- 6B5.9

- 6C8.3

- B4.5

- B5.9 G

- B5.9 GAS PLUS CM556

- ISB CM550

- ISB5.9G CM2180

- QSB3.9 30 CM550

- QSB5.9 30 CM550

- QSB5.9 44 CM550

Grouping of Compatible Engines

The engines listed can be grouped based on their series and specifications to provide a clearer understanding of their compatibility with the Clip part 3921815.

-

QSB Series:

- QSB3.9 30 CM550

- QSB5.9 30 CM550

- QSB5.9 44 CM550

-

ISB Series:

- ISB CM550

- ISB5.9G CM2180

-

B Series:

- B4.5

- B5.9 G

- B5.9 GAS PLUS CM556

-

Other Models:

- 4B3.9

- 6B5.9

- 6C8.3

This clip is engineered to meet the specific requirements of each engine model, ensuring a secure fit and optimal performance. Its compatibility across a wide range of Cummins engines underscores its versatility and importance in maintaining engine integrity 9.

Role of Part 3921815 Clip in Engine Systems

The 3921815 Clip is an essential component in the assembly and maintenance of various engine systems. Its primary function is to secure and maintain the proper alignment of components, ensuring the engine operates efficiently and reliably.

Arrangement

In the arrangement of engine components, the 3921815 Clip plays a significant role by holding parts in place. This is particularly important in the assembly of the cylinder block and cover, where precise alignment is necessary for optimal performance. The clip ensures that components are correctly positioned, reducing the risk of misalignment that could lead to operational issues 10.

Oil Fill System

The oil fill system is another area where the 3921815 Clip is utilized. It secures the oil fill cap and associated components, ensuring a tight seal. This is vital for maintaining the integrity of the lubrication system, preventing oil leaks, and ensuring that the engine receives the necessary lubrication for smooth operation. The clip’s reliable hold helps in maintaining consistent oil levels and pressure within the engine 11.

Cover

When it comes to the engine cover, the 3921815 Clip is used to secure the cover in place. This is important for protecting internal components from debris and contaminants. The clip ensures that the cover remains firmly attached, providing a barrier against external elements that could interfere with engine performance. Additionally, it aids in maintaining the structural integrity of the engine assembly 12.

Cylinder Block

In the cylinder block, the 3921815 Clip is employed to secure various attachments and components. This includes gaskets, sensors, and other small parts that are essential for the cylinder block’s function. By ensuring these components are held in place, the clip contributes to the overall stability and performance of the cylinder block, which is fundamental to the engine’s operation 13.

Conclusion

Overall, the 3921815 Clip is a versatile and reliable component that enhances the functionality and durability of engine systems by securing and aligning critical parts. Its compatibility with a wide range of Cummins engines underscores its importance in maintaining engine integrity and ensuring optimal performance 14.

-

Boyce, M. P. (2011). Gas Turbine Engineering Handbook (4th ed.). Butterworth-Heinemann.

↩ -

Rajamani, R. (2005). Vehicle Dynamics and Control. Springer.

↩ -

Giles, T. (2019). Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5612959.

↩ -

Boyce, M. P. (2011). Gas Turbine Engineering Handbook (4th ed.). Butterworth-Heinemann.

↩ -

Rajamani, R. (2005). Vehicle Dynamics and Control. Springer.

↩ -

Giles, T. (2019). Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5612959.

↩ -

Boyce, M. P. (2011). Gas Turbine Engineering Handbook (4th ed.). Butterworth-Heinemann.

↩ -

Rajamani, R. (2005). Vehicle Dynamics and Control. Springer.

↩ -

Giles, T. (2019). Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5612959.

↩ -

Boyce, M. P. (2011). Gas Turbine Engineering Handbook (4th ed.). Butterworth-Heinemann.

↩ -

Rajamani, R. (2005). Vehicle Dynamics and Control. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.