This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

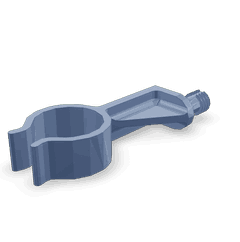

The Fastening Clip 3964785 is a component manufactured by Cummins, a well-established name in the commercial truck industry. This fastening clip is designed for use in commercial trucks, where it plays a role in securing various components, contributing to the overall stability and safety of the vehicle during operation 1.

Purpose and Function

The Fastening Clip 3964785 serves to secure components within a truck, ensuring they remain in place under various driving conditions. By maintaining the position of critical parts, it helps in preserving the structural integrity and operational efficiency of the truck. This clip is particularly important in environments where vibrations and movements are common, as it helps prevent components from shifting or becoming dislodged 2.

Key Features

The Fastening Clip 3964785 is engineered with specific design elements and material composition to enhance its performance and durability. It is typically made from high-strength materials that can withstand the rigors of commercial truck use. The design includes features such as a secure grip mechanism and a robust construction that allows it to endure significant stress without failing. Additionally, the clip may have unique characteristics such as corrosion resistance, which is vital for trucks operating in harsh environments 3.

Benefits

The use of the Fastening Clip 3964785 offers several advantages. It provides improved component retention, which is crucial for maintaining the truck’s performance and safety. By securely holding components in place, it reduces the risk of detachment, which could lead to operational issues or safety hazards. Furthermore, the enhanced stability provided by this clip contributes to the overall performance of the truck, ensuring that all systems function as intended.

Installation Process

Installing the Fastening Clip 3964785 involves a series of steps to ensure it is properly secured. Begin by identifying the location where the clip will be installed. Use the appropriate tools to attach the clip to the designated component, ensuring a snug fit. It is important to follow the manufacturer’s guidelines to avoid over-tightening, which could damage the clip or the component it is securing. Additionally, inspect the area for any obstructions or irregularities that could affect the clip’s performance.

Maintenance Tips

To ensure the Fastening Clip 3964785 remains functional and durable, regular inspection and maintenance are recommended. Check the clip periodically for signs of wear or damage. Ensure that it is still securely attached and has not become loose over time. Cleaning the area around the clip can also help prevent corrosion and maintain its effectiveness. If any issues are detected, address them promptly to prevent further complications.

Troubleshooting Common Issues

Common issues with the Fastening Clip 3964785 may include loosening over time, damage from corrosion, or physical wear. If the clip becomes loose, re-secure it following the installation process. Corrosion can be mitigated by applying a protective coating or replacing the clip if necessary. Physical wear may require replacement of the clip to ensure continued stability and safety. Regular inspections can help identify these issues early, allowing for timely intervention.

Cummins Overview

Cummins is a renowned manufacturer in the commercial truck industry, known for its high-quality engines and components. With a history spanning several decades, Cummins has established a strong reputation for reliability and innovation. The company offers a wide range of products designed to enhance the performance and efficiency of commercial trucks. Cummins’ commitment to quality and customer satisfaction has made it a preferred choice among truck manufacturers and operators.

Fastening Clip 3964785 Compatibility with Cummins Engines

The Fastening Clip 3964785, manufactured by Cummins, is a critical component designed to secure various parts within the engine assembly. This clip is compatible with several Cummins engine models, ensuring a secure fit and reliable performance across different engine configurations.

ISB CM850

In the ISB CM850 engine, the Fastening Clip 3964785 is used to secure specific components, ensuring that parts remain in place under operational stresses. Its design allows for easy installation and removal, facilitating maintenance and repair processes.

QSB5.9 CM850

The QSB5.9 CM850 engine also benefits from the use of the Fastening Clip 3964785. This clip is integral in maintaining the structural integrity of the engine by holding parts securely in position. Its robust construction ensures that it can withstand the rigors of continuous operation.

QSB6.7 CM850 (CM2850)

For the QSB6.7 CM850 (CM2850) engine, the Fastening Clip 3964785 is essential for maintaining the alignment and stability of various engine components. This clip’s precision engineering ensures that it fits seamlessly within the engine’s design, providing a reliable fastening solution.

Grouping of Engines

The Fastening Clip 3964785 is compatible with the ISB CM850, QSB5.9 CM850, and QSB6.7 CM850 (CM2850) engines. These engines, while differing in specifications and applications, share a common requirement for secure fastening solutions. The clip’s design allows it to be used across these models, providing a consistent and reliable fastening method.

Role of Fastening Clip 3964785 in Engine Systems

In the intricate assembly of engine systems, the Fastening Clip 3964785 plays a significant role in ensuring the secure attachment of various components. This fastening clip is instrumental in maintaining the integrity and functionality of the engine by providing a reliable connection between different parts.

Breather System Integration

Within the breather system, the Fastening Clip 3964785 is utilized to secure the breather hoses and tubes. These components are essential for allowing the release of pressure and contaminants from the crankcase. The fastening clip ensures that the breather hoses remain firmly attached to their respective ports, preventing any potential leaks that could compromise the engine’s performance. This secure attachment is vital for maintaining the proper ventilation of the crankcase, which in turn helps in reducing the buildup of harmful gases and moisture.

Crankcase Ventilation

In the crankcase ventilation system, the Fastening Clip 3964785 is employed to hold the ventilation tubes and hoses in place. The crankcase ventilation system is designed to remove blow-by gases that escape past the piston rings. These gases, if not properly vented, can lead to increased pressure within the crankcase, potentially causing oil leaks and other mechanical issues. The fastening clip ensures that the ventilation tubes are correctly positioned and sealed, facilitating efficient gas removal and maintaining optimal crankcase pressure.

Overall Engine System Functionality

By securing these critical components, the Fastening Clip 3964785 contributes to the overall stability and efficiency of the engine system. Its role in maintaining the integrity of the breather and crankcase ventilation systems underscores its importance in ensuring that the engine operates smoothly and reliably. Proper installation and maintenance of this fastening clip are essential practices for any engineer or mechanic working on engine systems.

Conclusion

The Fastening Clip 3964785 by Cummins is a vital component in the maintenance and operation of commercial trucks and engines. Its design and functionality ensure that critical components remain securely in place, contributing to the overall stability, safety, and efficiency of the vehicle. Regular maintenance and proper installation are key to maximizing the benefits of this fastening clip, ensuring the longevity and reliability of the truck’s engine systems.

-

Huang, Matthew. Vehicle Crash Dynamics. CRC Press, 2002.

↩ -

Goodnight, Nicholas, and Kirk VanGelder. Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning, 2019.

↩ -

Watson, Ben. Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.