This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

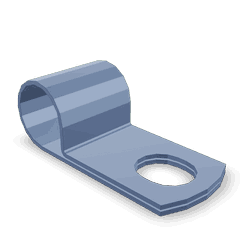

Cummins Inc. is renowned in the commercial truck industry for its high-quality engines and components. Among its offerings is the Cummins Part #4026251 Clip, a component crucial for the secure attachment of various components, ensuring the structural integrity and efficient operation of commercial trucks 1.

Purpose and Function

This Cummins part plays a significant role in truck operations by securing components in place. It contributes to the overall stability and safety of the vehicle by ensuring that parts remain firmly attached under various driving conditions. The clip is particularly important in maintaining the structural integrity of the truck, as it helps prevent components from becoming dislodged or damaged during transit 2.

Key Features

The 4026251 Clip is engineered with specific design and material characteristics to enhance its performance. It is constructed from durable materials that offer resistance to environmental factors such as moisture, corrosion, and extreme temperatures. These attributes ensure that the clip remains functional and reliable over time. Additionally, the clip is designed for ease of installation, allowing for quick and straightforward attachment to the necessary components 3.

Benefits

The advantages provided by the 4026251 Clip include enhanced safety, reliability, and efficiency in truck operations. By securely holding components in place, it contributes to the overall performance and longevity of the vehicle. The clip’s durable construction and resistance to environmental factors ensure that it maintains its functionality, reducing the likelihood of component failure and the need for frequent replacements.

Installation Process

Proper installation of the 4026251 Clip is crucial for ensuring its correct functionality and safety. The installation process involves several steps, beginning with the identification of the correct attachment points on the truck. The clip should be aligned with these points and secured according to the manufacturer’s guidelines. Adhering to these instructions ensures that the clip is installed correctly and performs its intended function effectively.

Maintenance and Troubleshooting

Regular inspection and maintenance of the 4026251 Clip are important for ensuring its continued reliability. Operators should check the clip for signs of wear, corrosion, or damage during routine maintenance checks. Common issues that may arise include loosening of the clip or damage to the attachment points. Troubleshooting these issues typically involves re-securing the clip or replacing it if it is damaged. Following manufacturer guidelines for maintenance can help prevent these issues and ensure the clip remains in optimal condition.

Safety Considerations

When handling and installing the 4026251 Clip, it is important to observe safety protocols and precautions. This includes wearing appropriate personal protective equipment (PPE) and ensuring that the truck is securely parked and the engine is off during installation. Adhering to safety standards helps prevent accidents and injuries, ensuring a safe working environment for all personnel involved in the installation process.

Cummins Overview

Cummins Inc. has a long-standing reputation for quality and reliability in the commercial vehicle industry. Founded in 1919, the company has grown to become a global leader in the design, manufacture, and distribution of engines and related technologies. Cummins’ product range includes engines, filtration systems, powertrain components, and emission control systems, all designed to meet the demanding requirements of commercial trucks and other heavy-duty applications. The company’s commitment to innovation and customer satisfaction has solidified its position as a trusted provider of automotive and heavy-duty truck parts.

Role of Part 4026251 Clip in Engine Systems

The 4026251 Clip is a critical component in the assembly and maintenance of various engine systems. Its primary function is to secure and hold different parts together, ensuring stability and proper operation of the engine.

Brake System

In the brake system, the 4026251 Clip is used to secure brake lines and components. It ensures that the brake lines remain firmly in place, preventing any unwanted movement that could lead to brake failure. The clip also helps in maintaining the integrity of the brake system by keeping the components aligned and reducing the risk of wear and tear.

Engine System

Within the engine system, the 4026251 Clip plays a significant role in securing various engine components. It is commonly used to hold engine mounts, ensuring that the engine remains stable within the vehicle’s frame. Additionally, the clip is employed in securing wiring and hoses, preventing them from vibrating loose or coming into contact with moving parts, which could cause damage.

Harness (Engine Brake) Kit

In the harness (engine brake) kit, the 4026251 Clip is vital for securing the harness to the engine and other components. This ensures that the electrical connections remain intact and that the harness does not interfere with the operation of the engine. The clip helps in organizing the harness, making it easier to access and maintain.

Wiring Harness Kit

For the wiring harness kit, the 4026251 Clip is used to secure wires and connectors in place. This is particularly important in high-vibration environments, such as within an engine compartment. The clip ensures that the wiring remains organized and protected, reducing the risk of short circuits or damage to the electrical system.

Conclusion

Overall, the 4026251 Clip is a versatile component that enhances the reliability and performance of engine systems by ensuring that all parts remain securely in place. Its durable construction and ease of installation make it an essential part for maintaining the structural integrity and efficiency of commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.