This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

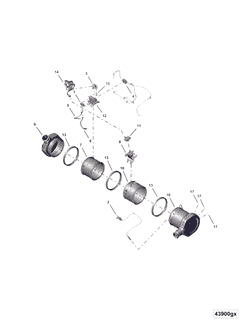

Cummins is a prominent player in the commercial truck industry, known for its high-quality engines and components that enhance truck performance and reliability. One such component is Part #4394681, a clip manufactured by Cummins. This part holds significance in truck maintenance and operation, contributing to the secure assembly and efficient functioning of various truck systems.

Purpose and Function

The 4394681 Clip serves a specific role in truck operations by securing components within the truck’s system. It ensures that parts are held firmly in place, which is vital for the proper assembly and functioning of the truck. By maintaining the integrity of component placement, the clip helps in the smooth operation of the truck’s systems 1.

Key Features

This Cummins part is designed with several key features that enhance its performance and durability. It is made from high-quality materials that offer resistance to wear and corrosion. The clip’s design includes attributes that allow for a secure fit, ensuring that components remain in place under various operating conditions. Additionally, any unique characteristics of the clip, such as its shape or additional functionalities, contribute to its overall effectiveness in truck applications 2.

Benefits

Using the 4394681 Clip offers several benefits. It improves the reliability of truck systems by ensuring that components are securely fastened. The clip is designed for ease of installation, which can save time during maintenance procedures. Furthermore, its contribution to the overall performance of the truck underscores its value in maintaining efficient truck operations 3.

Installation Process

Installing this part requires following a step-by-step process to ensure proper placement and function. The process involves identifying the correct location for the clip, using the appropriate tools for installation, and observing safety precautions to prevent injury or damage. Detailed instructions should be followed to achieve a secure and effective installation 4.

Maintenance and Troubleshooting

To ensure the longevity and optimal performance of the 4394681 Clip, regular maintenance is recommended. This includes checking the clip for signs of wear or damage and replacing it if necessary. Common issues that may arise with the clip can often be addressed through simple troubleshooting methods, such as ensuring proper installation or tightening if it has become loose.

Safety Considerations

When handling and installing the 4394681 Clip, it is important to follow safety practices and precautions. This includes wearing appropriate personal protective equipment, ensuring the work area is clean and free of hazards, and following all manufacturer guidelines for installation and maintenance. These safety measures help prevent accidents and ensure the well-being of those working with the clip.

Cummins Corporation

Cummins Corporation has a rich history in the commercial truck industry, known for its innovative products and commitment to quality. The company offers a wide range of engines and components designed to enhance truck performance and reliability. Cummins’ dedication to innovation and quality is evident in its product lineup, which includes the 4394681 Clip, a testament to the company’s expertise in the field.

Role of Part 4394681 Clip in Aftertreatment Device Systems

In the context of aftertreatment device systems, the 4394681 Clip is instrumental in ensuring the secure and efficient operation of various components. This clip is designed to facilitate the attachment and alignment of components within the aftertreatment system, which is essential for the reduction of emissions and the overall performance of the engine.

Integration with Diesel Particulate Filter (DPF)

The 4394681 Clip is often utilized in the assembly of the Diesel Particulate Filter (DPF). It helps in maintaining the structural integrity of the DPF by securing it in place, which is vital for the filter’s ability to trap and reduce particulate matter from the exhaust gases. Proper attachment ensures that the DPF operates within its designed parameters, enhancing its longevity and effectiveness.

Connection to Selective Catalytic Reduction (SCR) System

In Selective Catalytic Reduction (SCR) systems, the 4394681 Clip plays a role in securing the urea injection components. This includes the injectors and associated piping, which are critical for the precise delivery of urea into the exhaust stream. Accurate and consistent urea delivery is necessary for the conversion of nitrogen oxides (NOx) into harmless nitrogen and water vapor, thereby meeting emissions standards.

Support for Exhaust Gas Recirculation (EGR) Cooler

The clip is also employed in the Exhaust Gas Recirculation (EGR) Cooler setup. By ensuring a firm connection between the cooler and the surrounding components, it aids in the efficient recirculation of exhaust gases back into the engine. This process helps in lowering the combustion temperature, which in turn reduces NOx emissions.

Facilitation of Pressure Sensor Mounting

Part 4394681 Clip is used in the mounting of pressure sensors within the aftertreatment system. These sensors are crucial for monitoring the pressure differential across components like the DPF. Secure mounting ensures that the sensors provide accurate readings, which are used by the engine control unit (ECU) to make real-time adjustments for optimal performance and emissions control.

Role in Maintaining System Integrity

Overall, the 4394681 Clip contributes to the maintenance of system integrity by providing a reliable means of attachment for various aftertreatment components. Its role in securing these parts ensures that they function as intended, contributing to the efficient operation of the entire aftertreatment system.

Conclusion

The 4394681 Clip is a vital component in the maintenance and operation of commercial trucks, particularly within aftertreatment device systems. Its design and functionality are crucial for securing components, ensuring system integrity, and contributing to the efficient operation of the truck. Regular maintenance and proper installation of this part are essential for the longevity and performance of the truck’s systems.

-

Mom, Gijs. The Evolution of Automotive Engineering: A Handbook. SAE International, 2023.

↩ -

Norman, Andrew. Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc, 2016.

↩ -

Schneider, Wolf-Henning. Pistons and Engine Testing. Springer Nature, 2016.

↩ -

Cummins Inc. Operation and Maintenance Manual for ISL8.9 CM2880 L112. Bulletin Number 4358494.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.