This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

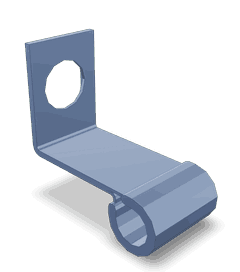

Cummins is a prominent player in the commercial truck industry, known for its robust and reliable diesel engines and components. Among its extensive range of parts is the Cummins Part #4913764 Clip, a component that plays a significant role in truck maintenance and operation. This part is designed to enhance the functionality and reliability of commercial trucks, ensuring they operate efficiently and safely.

Purpose and Function

The Cummins Part #4913764 Clip serves a specific purpose within the framework of commercial trucks. It is primarily used for securing various components, ensuring they remain in place and function correctly. The clip operates by providing a secure attachment point, which is crucial for the stability and performance of the truck’s systems. Its role in maintaining the integrity of the truck’s components cannot be understated, as it contributes to the overall efficiency and safety of the vehicle 1.

Key Features

This Cummins part is characterized by several key features that enhance its performance and durability. It is made from high-quality materials, ensuring it can withstand the rigors of commercial truck operation. The design of the clip is tailored to provide a strong and reliable hold, with precise engineering that allows for easy installation and removal when necessary. Additionally, the clip may feature unique attributes such as corrosion resistance or a specialized shape that improves its functionality in specific applications 2.

Benefits

Utilizing the Cummins Part #4913764 Clip offers several benefits. It contributes to improved reliability by securely holding components in place, which is vital for the consistent performance of the truck. The ease of installation is another advantage, allowing for quick replacement or adjustment as needed. Furthermore, the clip’s design and material composition ensure it can endure the demanding conditions of commercial truck use, thereby enhancing the overall performance and longevity of the vehicle 3.

Installation Process

Installing the Cummins Part #4913764 Clip requires attention to detail to ensure it is securely and effectively placed. The process involves identifying the correct location for the clip, using the appropriate tools to attach it, and verifying that it is firmly in place. Best practices include checking for any signs of wear or damage before installation and ensuring that all components are clean and free from debris. Following these steps helps to guarantee that the clip performs its intended function without issue.

Maintenance and Troubleshooting

To ensure the longevity and optimal performance of the 4913764 Clip, regular maintenance is recommended. This includes periodic inspections for signs of wear, corrosion, or damage. If any issues are detected, such as the clip becoming loose or showing signs of fatigue, it should be addressed promptly. Troubleshooting may involve tightening the clip, cleaning the attachment area, or replacing the clip if it is beyond repair. Adhering to these maintenance practices helps to prevent potential problems and ensures the clip continues to function effectively.

Compatibility and Applications

The Cummins Part #4913764 Clip is designed for use in specific types of trucks and models, ensuring compatibility and optimal performance. It is important to use manufacturer-recommended parts to maintain the integrity and efficiency of the truck’s systems. This clip is commonly applied in scenarios where secure component attachment is critical, highlighting the importance of selecting the right part for the job.

Safety Considerations

When installing or maintaining the Cummins Part #4913764 Clip, it is important to follow safety practices to protect both the installer and the vehicle. This includes wearing appropriate personal protective equipment (PPE) such as gloves and safety glasses. Additionally, operational safety measures should be observed, such as ensuring the truck is turned off and the area is secure before beginning work. These precautions help to prevent accidents and ensure a safe working environment.

Role of Part 4913764 Clip in Engine Systems

The part 4913764 Clip is integral to the functionality and reliability of various engine components. Its primary role is to secure and maintain the alignment of parts, ensuring optimal performance and safety.

Mounting Systems

In mounting systems, the 4913764 Clip is used to fasten components securely to the engine block or other structural elements. This secure attachment is essential for withstanding the vibrations and stresses that occur during engine operation. The clip ensures that parts remain in their designated positions, which is vital for the proper functioning of the mounting system. It helps in distributing the load evenly across the mounting points, reducing the risk of component failure or misalignment.

Engine Brake Systems

Within engine brake systems, the 4913764 Clip plays a significant role in maintaining the integrity of the braking mechanism. It is often used to secure brake components, such as actuators or linkage parts, ensuring they operate within specified parameters. The clip’s reliable hold prevents unwanted movement or detachment, which could lead to inefficient braking or even failure. This is particularly important in heavy-duty applications where the engine brake is relied upon for safe deceleration and control.

Conclusion

In both applications, the 4913764 Clip contributes to the overall stability and efficiency of the engine system. Its role in securing and aligning components is fundamental to the sustained performance and durability of the engine. Regular maintenance and proper installation are essential to ensure the clip continues to function effectively, contributing to the overall reliability and safety of commercial trucks.

-

Parikyan, T. (Ed.). (2022). Advances in Engine and Powertrain Research and Technology. Springer Nature.

↩ -

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩ -

Awari, G.K., Kumbhar, V.S., & Tirpude, R.B. (2011). Automotive Systems Principles and Practice. CRC Press.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.