This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

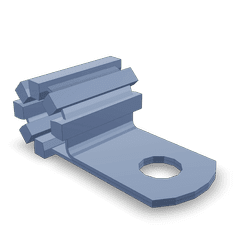

The Cummins 4944961 Clip is a component utilized in the maintenance and operation of commercial trucks. This clip serves a specific function within the truck’s system, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance is vital for maintaining the optimal performance of commercial trucks 1.

Purpose and Function

This Cummins part plays a role in the secure attachment and alignment of components within a truck’s system. By ensuring that parts are correctly positioned and held in place, the clip contributes to the smooth operation of the truck. Its function is integral to maintaining the integrity of the truck’s systems, facilitating efficient performance and reducing the likelihood of component misalignment or detachment 2.

Key Features

The 4944961 Clip is designed with specific attributes that enhance its performance and durability. Crafted from high-quality materials, the clip is built to withstand the rigors of commercial truck operation. Its design allows for easy installation and removal, while its material composition ensures resistance to wear and corrosion. These features contribute to the clip’s reliability and longevity in demanding environments 3.

Benefits

Utilizing the 4944961 Clip offers several benefits. It improves component security by ensuring parts remain in their intended positions, which can lead to enhanced system efficiency. Additionally, the clip may contribute to potential cost savings by reducing the need for frequent maintenance due to component misalignment or failure. Its design and material composition also support durability, further contributing to its value in truck maintenance 4.

Installation and Usage

Proper installation and usage of the 4944961 Clip are crucial for its effectiveness. Guidelines for installation may include ensuring the clip is correctly aligned with the components it secures, applying the appropriate amount of force during installation to avoid damage, and verifying that the clip is fully engaged. Best practices for usage involve regular inspection to ensure the clip remains in good condition and properly seated 5.

Troubleshooting and Maintenance

Common issues with the 4944961 Clip may include signs of wear or damage, which can affect its ability to secure components effectively. Troubleshooting may involve inspecting the clip for cracks, deformation, or corrosion. Maintenance tips to ensure the clip’s longevity and optimal performance include regular inspection and replacement as necessary, adhering to manufacturer guidelines for usage and installation 6.

Compatibility and Applications

The 4944961 Clip is designed for use with specific truck models and systems, ensuring compatibility and effective performance. Its applications span various types of commercial trucks and engine configurations, making it a versatile component in the maintenance and operation of these vehicles 7.

Safety Considerations

When working with the 4944961 Clip, it is important to observe safety considerations. This includes proper handling to avoid injury, taking precautions during installation to prevent damage to the clip or surrounding components, and adhering to manufacturer guidelines for usage and maintenance. Following these safety practices helps ensure the clip’s effective and safe use in truck maintenance 8.

Cummins Overview

Cummins Inc. is a leader in the diesel engine manufacturing industry, with a history of providing high-quality components for the commercial trucking sector. The company’s expertise and commitment to quality are reflected in its wide range of products, including the 4944961 Clip, which is designed to meet the demanding requirements of commercial truck operation 9.

Cummins Engine Compatibility with Part 4944961

This Cummins part is designed to fit a variety of Cummins engines, ensuring compatibility across different models. This clip is integral for maintaining the structural integrity and operational efficiency of the engines it is used with. Here is a detailed look at the engines that this part fits:

B3.3 Series

- B3.3

- QSB3.3 CM2150

- QSB3.3 CM2250 EC

The B3.3 series engines, including the QSB3.3 CM2150, QSB3.3 CM2250 EC, and the base B3.3 model, all utilize the part 4944961. This clip is essential for securing various components within these engines, ensuring that they remain properly aligned and function as intended.

L9 Series

- L9 CM2670

- L128B

The L9 series engines, specifically the L9 CM2670 and L128B, also incorporate the part 4944961. This clip is critical for maintaining the alignment and stability of components within these engines, contributing to their overall performance and longevity.

QSC Series

- QSC8.3 CM850 (CM2850)

- QSC9 CM2250 / QSL9 CM2250

The QSC8.3 CM850 (CM2850) and the QSC9 CM2250 / QSL9 CM2250 engines are designed to use the part 4944961. This clip plays a vital role in ensuring that the components within these engines are held securely in place, which is crucial for the engines’ operational efficiency.

QSB4.5 Series

- QSB4.5 CM2250 EC

The QSB4.5 CM2250 EC engine also fits the part 4944961. This clip is essential for maintaining the structural integrity of the engine, ensuring that all components are properly aligned and secured.

By ensuring compatibility with these various engines, the part 4944961 plays a crucial role in maintaining the performance and reliability of Cummins engines across different models and series.

Role of Part 4944961 Clip in Engine Systems

The 4944961 Clip is an essential component in the integration and securement of various engine systems. Its application spans across multiple subsystems, ensuring the reliable operation and safety of the engine.

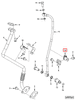

Gauge and Oil Level Systems

In gauge and oil level systems, the 4944961 Clip is utilized to secure wiring and sensor connections. It plays a significant role in maintaining the integrity of the electrical connections that transmit data from the oil level sensors to the gauges. This ensures accurate readings and timely notifications of oil levels, contributing to the overall maintenance and performance of the engine.

Harness and Electronic Control Module (ECM) Wiring

The clip is integral in the assembly of harnesses and ECM wiring. It secures the wiring to the chassis and other structural components, preventing undue stress on the connections. This is particularly important in the ECM wiring, where stable and consistent electrical connections are vital for the proper functioning of the engine’s electronic controls.

Engine Control Wiring

In engine control wiring, the 4944961 Clip ensures that all control signals are transmitted without interference. It helps in organizing and securing the wiring, reducing the risk of short circuits or signal loss that could lead to engine malfunctions.

Plumbing Systems

For auxiliary pump, fuel, and turbocharger plumbing systems, the clip is used to secure hoses and pipes to the engine frame. This is important for maintaining the alignment and integrity of the plumbing, ensuring that fluids are delivered efficiently and without leaks.

Wiring Brace

The clip also serves as a wiring brace, providing additional support to wiring bundles. This is especially important in high-vibration environments, where unsecured wiring could lead to fatigue and eventual failure of the electrical connections.

In summary, the 4944961 Clip is a versatile component that enhances the reliability and performance of various engine systems by ensuring secure and organized connections and plumbing.

Conclusion

The Cummins 4944961 Clip is a critical component in the maintenance and operation of commercial trucks. Its role in securing and aligning components within the truck’s system contributes to the vehicle’s overall efficiency and reliability. Understanding its purpose, features, benefits, and proper installation and maintenance practices is essential for ensuring the optimal performance of commercial trucks. By adhering to safety considerations and manufacturer guidelines, users can maximize the effectiveness and longevity of this part in their truck maintenance routines.

-

Saiful Bari, Diesel Engine Combustion, Emissions and Condition Monitoring, InTech, 2013.

↩ -

Haoran Hu, Rudy Smaling, and Simon Baseley, Heavy-Duty Wheeled Vehicles, SAE International, 2014.

↩ -

D. K. Singh, Dictionary of Mechanical Engineering, Springer Nature, 2024.

↩ -

Pawel Drozdziel, The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects, Routledge, 2023.

↩ -

Cummins Inc., Operation and Maintenance Manual, Bulletin Number 5659690, Z13 CM2880 Z104G.

↩ -

Cummins Inc., Operation and Maintenance Manual, Bulletin Number 5659690, Z13 CM2880 Z104G.

↩ -

Cummins Inc., Operation and Maintenance Manual, Bulletin Number 5659690, Z13 CM2880 Z104G.

↩ -

Cummins Inc., Operation and Maintenance Manual, Bulletin Number 5659690, Z13 CM2880 Z104G.

↩ -

Cummins Inc., Operation and Maintenance Manual, Bulletin Number 5659690, Z13 CM2880 Z104G.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.