Minimum Quantity 2

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

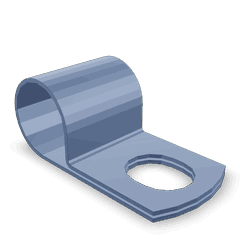

The Cummins 68152 Clip is a specialized component designed for use in commercial truck operations. Its primary role is to secure and maintain the integrity of various connections within the truck’s system, ensuring reliable performance and safety. This part is integral to the efficient operation of commercial trucks, contributing to the overall functionality and durability of the vehicle.

Purpose and Functionality

The Cummins 68152 Clip serves to secure hoses, wires, and other components within the truck’s system. By providing a stable and secure connection, the clip helps prevent disconnections and leaks, which can lead to system failures or inefficiencies. Its functionality is crucial in maintaining the structural and operational integrity of the truck’s various systems, ensuring that all components work harmoniously 1.

Key Features

This Cummins part is constructed from high-quality materials, designed to withstand the rigors of commercial truck operations. Key features include its durable material composition, which offers resistance to wear and corrosion. The clip’s design elements are tailored to provide a snug fit, ensuring that connections remain secure under various conditions. Additionally, the clip may feature unique characteristics such as anti-vibration properties, which enhance its performance and longevity 2.

Benefits

The use of the Cummins 68152 Clip offers several benefits. Its durable construction contributes to improved longevity, reducing the need for frequent replacements. The clip’s design allows for ease of installation, minimizing downtime during maintenance procedures. Furthermore, by ensuring secure connections, the clip contributes to the overall efficiency of the truck, enhancing performance and reliability 3.

Installation Process

Proper installation of the Cummins 68152 Clip is vital to ensure its effectiveness. The process involves identifying the correct location for the clip, ensuring that the connection it secures is clean and free from debris. Using the appropriate tools, the clip should be fitted snugly but not overly tight to avoid damage. Best practices include verifying the connection’s security after installation and conducting a test to ensure proper functionality 4.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 68152 Clip, regular maintenance is recommended. This includes periodic inspections to check for signs of wear, corrosion, or damage. Any issues identified should be addressed promptly to prevent further deterioration. Additionally, ensuring that connections remain clean and free from debris can help maintain the clip’s effectiveness.

Troubleshooting Common Issues

Common issues associated with the Cummins 68152 Clip may include clip failure or improper fitting. Troubleshooting steps involve inspecting the clip and connection for signs of wear or damage, ensuring that the clip is correctly fitted, and verifying that the connection is secure. Addressing these issues promptly can help maintain the clip’s functionality and prevent system failures.

Role in Truck Operation

The Cummins 68152 Clip plays a role in the overall operation of the truck by securing critical connections within the system. Its function is interconnected with various components, contributing to the truck’s efficiency and reliability. By ensuring that connections remain secure, the clip helps maintain the integrity of the truck’s systems, supporting smooth and efficient operation.

Manufacturer Overview - Cummins

Cummins is a renowned manufacturer with a rich history in the automotive and heavy-duty truck industries. Known for their expertise in producing high-quality components, Cummins is committed to innovation and quality. Their products, including the 68152 Clip, are designed with precision and reliability in mind, reflecting Cummins’ dedication to enhancing the performance and durability of commercial vehicles.

Compatibility with Cummins Engines

The 68152 Clip, manufactured by Cummins, is designed to fit a variety of engine models. This clip is integral in securing various components within the engine, ensuring they remain in place during operation. Here’s how it fits with the specified engines:

Cummins 6B5.9 Engines

The 6B5.9 engines utilize the 68152 clip to maintain the alignment and stability of certain engine parts, ensuring smooth operation and preventing any misalignment that could lead to performance issues.

Cummins B6.7 Engines

For the B6.7 engines, including variants like B6.7 CM2350 B135B, B6.7 CM2670 B153B, B6.7 CM2670 B164C, and B6.7 G CMOH6.0 B125, the 68152 clip is used to secure parts that require precise positioning. This includes components related to the fuel system and other critical areas.

Cummins C8.3 Engines

In the C8.3 engines, such as the C8.3 G, the 68152 clip is employed to hold parts in place, ensuring that the engine operates efficiently and reliably. This clip is crucial for maintaining the structural integrity of the engine components.

Cummins D4.0 Engines

The D4.0 CM2620 D103B engine also benefits from the 68152 clip, which is used to secure parts that are essential for the engine’s operation. This ensures that the engine runs smoothly and without any issues related to part misalignment.

Cummins F3.8 and F4.5 Engines

For the F3.8 CM2620 F137B and F4.5 CM2620 F139B engines, the 68152 clip is used to maintain the alignment of various components. This is crucial for the proper functioning of the engine and preventing any potential performance issues.

Cummins ISB Engines

The ISB series engines, including models like ISB CM2150, ISB CM550, ISB CM850, ISB/ISD4.5 CM2150 B119, ISB/ISD6.7 CM2150 SN, ISB4.5 CM2350 B104, ISB5.9 CM2880 B110, ISB5.9 CM2880 B127, ISB6.7 CM2250, ISB6.7 CM2350 B101, ISB6.7 G CM2180 B118, and ISBE CM2150, all utilize the 68152 clip to secure parts that are critical for the engine’s operation. This clip ensures that these parts remain in their correct positions, contributing to the engine’s overall efficiency and reliability.

Cummins C GAS PLUS CM556

In the C GAS PLUS CM556 engine, the 68152 clip is used to secure parts that are essential for the engine’s operation. This ensures that the engine runs smoothly and without any issues related to part misalignment.

Cummins G855

The G855 engine also utilizes the 68152 clip to maintain the alignment of various components. This is crucial for the proper functioning of the engine and preventing any potential performance issues.

Role of Part 68152 Clip in Various Engine Systems

The 68152 Clip is integral to the secure and efficient operation of several engine components. Its application spans across multiple systems, ensuring that each component functions as intended.

Accessory and Drive Systems

In the Accessory Drive Mtg and Accessory Kit, the 68152 Clip ensures that accessories are firmly mounted and aligned, reducing the risk of misalignment or detachment during operation. This is particularly important for components that require precise positioning to function correctly.

Compressor and Bracing

For the Compressor Brace Kit, the clip plays a role in maintaining the structural integrity of the compressor assembly. It helps in securing the brace, which is essential for absorbing vibrations and ensuring the compressor operates within its designed parameters.

Fuel System Components

In the Fuel Base Pump and Fuel Pump assemblies, the 68152 Clip is used to secure fuel lines and mounting brackets. This ensures that fuel delivery remains consistent and that there are no leaks or disruptions in the fuel supply. Additionally, in the Fuel Shutoff Valve and Mounting Fuel Bypass Tube, the clip helps in maintaining the valve’s position and ensuring it operates smoothly.

Electrical and Control Systems

The clip is also vital in the Engine Control Module (ECM) and ECM Plumbing. It secures wiring and plumbing connections, ensuring that electrical signals and fluid pathways remain intact. In the Engine Wiring and Wiring Harness Mounting, the clip helps in organizing and securing wires, preventing chafing and ensuring reliable electrical connections.

Oil System Components

For the Dipstick and Tube, Dipstick Kit, and Dipstick Mounting, the 68152 Clip ensures that the dipstick remains in place and is easy to access for oil level checks. In the Oil Gauge Mounting Bracket and Oil Gauge Plumbing, it secures the gauge and its plumbing, ensuring accurate oil pressure readings.

Safety and Structural Components

In the Safety Control and ISM Burn-Only Val/Mtg, the clip ensures that safety mechanisms are securely mounted and operational. This is essential for maintaining the engine’s safety protocols.

Overall, the 68152 Clip is a versatile component that enhances the reliability and performance of various engine systems by ensuring that critical components are securely mounted and properly aligned.

Conclusion

The Cummins 68152 Clip is a critical component in the operation and maintenance of commercial trucks and various Cummins engines. Its role in securing and maintaining the integrity of connections within the truck’s system ensures reliable performance and safety. The clip’s durable construction, ease of installation, and maintenance benefits contribute to the overall efficiency and reliability of the vehicle. Proper installation and regular maintenance are essential to maximize the clip’s functionality and longevity.

-

Moustafa ElGindy and Zeinab ElSayegh, Road and Off-Road Vehicle Dynamics, Springer Nature, 2023.

↩ -

A. J. Wharton, Diesel Engines, Butterworth-Heinemann Ltd, 1991.

↩ -

Konrad Reif Ed, Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems, Springer Vieweg, 2014.

↩ -

Richard D. Atkins, An Introduction to Engine Testing and Development, SAE International, 2009.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.