This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Compression springs are helical springs designed to resist compressive forces. They are widely used in mechanical systems for their ability to store and release energy efficiently. In commercial trucks, compression springs play a role in various applications, including suspension systems, valve trains, and clutch mechanisms. These springs operate on the principles of compression and elasticity, where they compress under load and return to their original shape when the load is removed 1.

Role of Compression Spring Part #144491 in Truck Operation

The Compression Spring Part #144491 by Cummins is specifically engineered to enhance the operation of truck systems. This spring is commonly utilized in the valve train mechanism, where it assists in maintaining proper valve clearance and ensuring smooth engine operation. By providing consistent pressure, it helps in the efficient opening and closing of valves, which is important for the engine’s performance 2.

Key Features of Compression Spring Part #144491

The Compression Spring Part #144491 is crafted from high-quality materials, ensuring durability and reliability in demanding truck applications. Its design specifications include precise coil diameter and wire gauge, which are optimized for maximum performance. Additionally, this spring may feature unique attributes such as corrosion-resistant coatings or specialized end configurations to enhance its functionality and longevity 3.

Benefits of Using Compression Spring Part #144491

Incorporating the Compression Spring Part #144491 into truck systems offers several advantages. It contributes to improved reliability by ensuring consistent valve operation, which can lead to enhanced engine performance. Fleet operators may also experience potential cost savings due to the spring’s durability, reducing the frequency of replacements and maintenance interventions.

Installation and Integration

Proper installation of the Compression Spring Part #144491 is crucial for optimal performance. It should be integrated into the truck’s valve train system with careful attention to compatibility with other components. During installation, it is important to follow manufacturer guidelines to ensure the spring is correctly positioned and secured. This may involve using appropriate tools and taking necessary precautions to avoid damage to the spring or surrounding parts.

Troubleshooting Common Issues

Compression springs in truck applications can encounter issues such as fatigue, deformation, or failure due to excessive loads or wear. Common problems may include inconsistent valve operation or engine performance issues. To troubleshoot these issues, a systematic approach should be taken. This involves inspecting the spring for signs of damage, checking for proper installation, and ensuring there are no obstructions or misalignments in the valve train system.

Maintenance Recommendations

To ensure the longevity and optimal performance of the Compression Spring Part #144491, regular maintenance is recommended. This includes periodic inspections to check for signs of wear or damage. Cleaning the spring and its surrounding components can prevent buildup of debris that may affect performance. Additionally, following the manufacturer’s guidelines for replacement intervals can help maintain engine efficiency and reliability.

Cummins: A Brief Overview

Cummins Inc. is a renowned manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a rich history of producing reliable and high-performance truck components, Cummins has established a strong reputation among fleet operators and maintenance professionals. The company’s product range includes a variety of engine and powertrain solutions, designed to meet the demanding requirements of modern trucking operations.

Compression Spring Part 144491 in Cummins Engines

The Compression Spring part number 144491, manufactured by Cummins, is a component in various Cummins engine models. This part is integral to the engine’s operation, providing support and functionality in the mechanical systems of the engines.

L10 Mechanical Engine

In the L10 Mechanical engine, the Compression Spring part 144491 plays a role in maintaining the integrity and efficiency of the engine’s internal mechanisms. It ensures that various parts remain securely in place, contributing to the engine’s overall performance and longevity.

N14 Mechanical Engine

Similarly, in the N14 Mechanical engine, the Compression Spring part 144491 is designed to handle the specific demands and operational conditions of this engine model. It is engineered to withstand the rigors of heavy-duty applications, providing reliable compression and support throughout the engine’s lifecycle.

Grouping of Engines

Both the L10 and N14 Mechanical engines benefit from the use of the Compression Spring part 144491 due to its robust design and high-quality materials. Cummins ensures that this part meets stringent standards, making it a reliable choice for maintaining the performance and durability of these engines.

Role of Part 144491 Compression Spring in Engine Systems

In the context of engine systems, the part 144491 Compression Spring is integral to the functionality and efficiency of several key components.

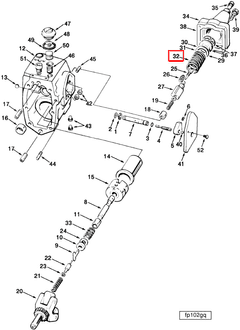

Fuel Pump System

The compression spring is utilized within the fuel pump system to maintain consistent pressure. It works in conjunction with the fuel pump to ensure that the fuel is delivered at the correct pressure to the engine. This is important for the proper atomization of fuel, which in turn affects combustion efficiency and overall engine performance.

Governor Maximum (Gov. Max.) System

In the Gov. Max. system, the compression spring helps in regulating the maximum speed of the engine. It interacts with the governor mechanism to apply the necessary force that limits the engine’s RPM, ensuring it operates within safe parameters.

Calibration and Fuel Code Systems

During the calibration process, the compression spring assists in setting the precise parameters for fuel delivery. It interacts with the fuel code and fuel pump code systems to fine-tune the fuel injection timing and pressure. This ensures that the engine runs efficiently under various operating conditions.

Fuel Base and Spring Interaction

The compression spring is also a component in the fuel base assembly. Here, it works alongside other springs and mechanical components to maintain the structural integrity and functional precision of the fuel base. This interaction is vital for the consistent delivery of fuel to the combustion chambers.

Overall Engine Efficiency

By playing a role in these systems, the compression spring contributes to the overall efficiency and reliability of the engine. It ensures that fuel is delivered at the right pressure and timing, and that the engine operates within its designed parameters, thereby enhancing performance and longevity.

Conclusion

The Compression Spring Part #144491 by Cummins is a critical component in the operation of commercial truck engines, particularly in the valve train mechanism. Its high-quality construction, precise design, and reliable performance make it an essential part for maintaining engine efficiency and durability. Proper installation, regular maintenance, and timely troubleshooting are key to maximizing the benefits of this Cummins part, ensuring optimal engine performance and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.