This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 173176 Compression Spring is a specialized component designed for use in commercial trucks. Its primary function is to provide necessary force and absorb energy within various truck systems. Compression springs are integral to mechanical systems, offering resilience and reliability in demanding applications. This spring, in particular, plays a significant role in ensuring the smooth operation of truck components 1.

Basic Concepts of Compression Springs

Compression springs are mechanical devices that store energy when compressed. They are widely used in various applications to absorb shock, maintain pressure, and return to their original shape once the force is removed. The principles of spring mechanics dictate that these springs operate based on Hooke’s Law, which states that the force needed to extend or compress a spring by some distance is proportional to that distance 2. In mechanical systems, compression springs help in absorbing and storing energy, which is then released to perform work.

Purpose of the 173176 Compression Spring in Truck Operation

The 173176 Compression Spring is specifically designed to enhance the functionality and efficiency of commercial truck components. It plays a role in systems where consistent force and energy absorption are required. By providing the necessary compression and rebound capabilities, this spring ensures that truck components operate smoothly and efficiently, contributing to the overall performance of the vehicle 3.

Key Features

The 173176 Compression Spring boasts several key features that enhance its performance and durability. It is crafted from high-quality materials, ensuring resilience under demanding conditions. The design specifications include precise coil diameters and wire thickness, which are optimized for the specific applications in commercial trucks. Additionally, the spring’s unique attributes, such as its corrosion resistance and fatigue strength, contribute to its longevity and reliability.

Benefits

Using the 173176 Compression Spring in truck applications offers several benefits. It provides improved performance by ensuring consistent force and energy absorption. The spring’s reliable design enhances the durability of truck components, reducing the need for frequent replacements. Moreover, its high-quality construction ensures that it can withstand varying operating conditions, contributing to the overall reliability of the truck.

Installation and Usage

Proper installation of the 173176 Compression Spring is crucial for optimal performance and longevity. It should be installed according to the manufacturer’s guidelines to ensure it functions correctly within the truck’s systems. Careful handling and correct placement are necessary to avoid damage and ensure the spring operates as intended.

Troubleshooting and Maintenance

Common issues with the 173176 Compression Spring can often be traced to improper installation or environmental factors. Regular inspection and maintenance are recommended to ensure the spring remains in good working condition. Signs of wear, such as deformation or corrosion, should be addressed promptly. Replacement guidelines should be followed to maintain the spring’s performance and prevent system failures.

Common Applications

The 173176 Compression Spring is typically used in various systems within commercial trucks. It is commonly found in suspension systems, where it helps absorb shocks and maintain ride quality. Additionally, it is used in braking systems to ensure consistent pressure and performance. Other applications include clutch systems and various engine components, where reliable force and energy absorption are required.

Performance Under Various Conditions

The 173176 Compression Spring is designed to perform reliably under different operating conditions. It can withstand varying temperatures, loads, and environments, making it suitable for use in demanding situations. Its resilience and reliability ensure that it continues to function effectively, even under extreme conditions, contributing to the truck’s overall performance.

Cummins Overview

Cummins Inc. is a leading manufacturer with a rich history in diesel engines and related technologies. The company is renowned for its commitment to quality and innovation in the automotive industry. Cummins’ expertise in designing and producing high-performance components, such as the 173176 Compression Spring, underscores its dedication to enhancing the reliability and efficiency of commercial trucks.

Compatibility with Various Engine Models

The 173176 Compression Spring, manufactured by Cummins, is designed to be a versatile component that fits seamlessly into various engine models. This spring is engineered to provide the necessary compression force in different engine applications, ensuring optimal performance and longevity.

Compatibility with K-Series Engines

The 173176 is compatible with several K-Series engines, including:

- K19: This engine benefits from the spring’s ability to maintain consistent compression, enhancing overall engine efficiency.

- K38: The spring’s design ensures that it can handle the specific demands of the K38 engine, providing reliable performance.

- K50: The spring’s robust construction is ideal for the K50 engine, supporting its operational requirements.

Compatibility with N-Series Engines

The 173176 also fits well with the following N-Series engines:

- N14 G: This engine model leverages the spring’s precision to achieve optimal compression, contributing to its performance.

- NH/NT 855: The spring’s compatibility with the NH/NT 855 engine ensures that it can withstand the rigorous demands of this model, providing consistent performance.

Compatibility with V-Series Engines

For V-Series engines, the 173176 is designed to meet the specific needs of:

- V28: The spring’s design is tailored to support the V28 engine, ensuring that it can handle the necessary compression forces effectively.

By integrating the 173176 into these engines, Cummins ensures that each model receives a component that is both reliable and efficient, contributing to the overall performance and durability of the engine.

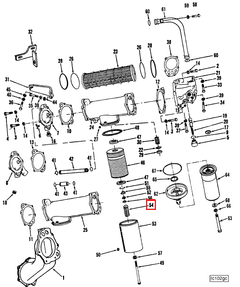

Role of Part 173176 Compression Spring in Engine Systems

Part 173176 Compression Spring is integral to the efficient operation of various engine components. In the assy. shell & bolt setup, it ensures proper tension and alignment, which is essential for the structural integrity and performance of the assembly.

Within the cooler lubricating filter and cooler lubricating oil filter, the compression spring assists in maintaining consistent pressure, which is vital for effective filtration and cooling of the lubricating oil. This helps in prolonging the life of the filter and ensuring optimal engine performance.

In the cylinder short block, the compression spring plays a role in valve operation, ensuring that valves open and close at the correct times and with the appropriate force. This is fundamental for the combustion process and overall engine efficiency.

The filter, lubricating oil, and filter and cooler mounting benefit from the spring’s ability to provide consistent pressure, which is crucial for the filter’s sealing and the cooler’s efficient operation.

For the filter cooler, filter lubricating oil duplex, and filter-cooler, the spring ensures that the components remain under the necessary pressure, enhancing their durability and effectiveness in filtering and cooling the oil.

In the gear box, the compression spring is used to maintain tension in various moving parts, ensuring smooth operation and reducing wear and tear.

The lub oil cooler, lube oil cooler, and lube oil filter & co systems rely on the spring to maintain pressure and ensure that the cooling and filtration processes are efficient.

For the lube oil filter v-555-m and lube oil filter-cooler, the spring’s role is to provide the necessary tension for the filter elements, ensuring they function correctly.

In the lubricating oil duplex filter and lubricating oil filter, the compression spring helps in maintaining the filter media’s position and pressure, which is essential for effective filtration.

The lubricating oil filter cooler and lubricating oil pump and filter systems use the spring to ensure that the pump and filter components operate under the correct pressure, enhancing their performance and longevity.

The lubricating pump and filter assembly and mounting l.o filter setups also benefit from the spring’s consistent pressure, which is vital for the assembly’s structural integrity and operational efficiency.

In the oil filter & gages and oil filter / cooler systems, the compression spring ensures that the filter elements are held in place under the right pressure, which is crucial for accurate gage readings and effective oil filtration.

Lastly, in the spare parts kit, the inclusion of part 173176 Compression Spring ensures that maintenance and repair tasks can be performed with the correct components, maintaining the engine’s performance and reliability.

Conclusion

The Cummins 173176 Compression Spring is a critical component in the operation of commercial trucks and various engine systems. Its design and features ensure reliable performance under demanding conditions, contributing to the overall efficiency and durability of the vehicle. Proper installation, maintenance, and understanding of its applications are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.