This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 177055 Compression Release Lever is a component designed to enhance the operation of heavy-duty trucks by facilitating engine braking. This part plays a significant role in the engine’s ability to manage vehicle speed and control during descents, contributing to overall safety and efficiency in heavy-duty truck operations.

Basic Concepts of Compression Release Levers

A Compression Release Lever is a mechanical device used in diesel engines to momentarily release compression in the cylinders. This action allows the engine to act as a brake, slowing the vehicle without relying solely on the traditional braking system. By interrupting the normal compression cycle, the engine can resist the motion of the crankshaft more effectively, thus aiding in deceleration 1.

Purpose of the 177055 Compression Release Lever

The 177055 Compression Release Lever is specifically engineered for Cummins engines. It plays a role in the engine braking system by allowing the release of compression in the cylinders at the appropriate moments. This mechanism helps in managing the vehicle’s speed on descents, reducing the load on the braking system, and enhancing control and safety 2.

Key Features

The 177055 is constructed with precision to ensure durability and efficiency. It is made from high-quality materials that can withstand the rigors of heavy-duty truck operations. The design includes mechanical advantages that ensure smooth operation and reliable performance. Unique attributes of this lever include its integration with Cummins engine systems, ensuring compatibility and optimal function 3.

Benefits

The advantages provided by the 177055 Compression Release Lever include improved engine braking efficiency, which allows for better vehicle control during descents. It also contributes to reduced wear on the braking systems, extending their lifespan. Additionally, the lever enhances overall vehicle control, making it a valuable component for safety and operational efficiency in heavy-duty trucks 4.

Installation and Integration

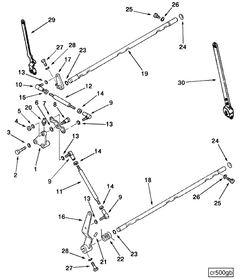

Proper installation of the 177055 within Cummins engine systems requires adherence to specific guidelines. This includes ensuring correct alignment and securing the lever in place. Any necessary adjustments or configurations should be performed according to the manufacturer’s recommendations to ensure optimal integration and function.

Troubleshooting Common Issues

Common problems associated with the 177055 may include issues with engagement or disengagement during operation. Troubleshooting steps may involve checking for proper installation, ensuring there is no obstruction in the mechanism, and verifying that all connections are secure. Solutions may range from simple adjustments to more complex repairs, depending on the issue identified.

Maintenance Recommendations

To ensure optimal performance and longevity of the 177055, regular maintenance is recommended. This includes periodic inspections for wear or damage, ensuring all moving parts are lubricated as needed, and replacing the lever at recommended intervals or when signs of failure are detected. Adhering to these best practices will help maintain the efficiency and reliability of the engine braking system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history of innovation and quality, Cummins has established a strong reputation within the automotive and heavy-duty truck industries. The company’s product offerings are known for their reliability, performance, and efficiency, making them a preferred choice for professionals in the field.

Conclusion

The Cummins 177055 Compression Release Lever is a critical component for enhancing the safety and efficiency of heavy-duty trucks. Its role in facilitating engine braking, reducing wear on traditional braking systems, and improving vehicle control during descents underscores its importance in heavy-duty truck operations. Proper installation, maintenance, and troubleshooting are essential to ensure the optimal performance of this Cummins part.

-

Pacejka, Hans B. Tyre and Vehicle Dynamics. Butterworth-Heinemann, 2006.

↩ -

Hilgers, Michael. Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature, 2023.

↩ -

Rendle, Steve, and Martynn Randall. Haynes Diesel Engine Systems and Data Book. Haynes Publishing, 2000.

↩ -

Huang, Matthew. Vehicle Crash Dynamics. CRC Press, 2002.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.