This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

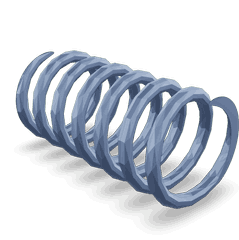

The Cummins 179836 Compression Spring is a specialized component designed for use in commercial trucks. Its purpose is to provide necessary force and support within various mechanical systems of the truck. Understanding its function and significance is vital for maintaining the efficiency and reliability of truck operations.

Basic Concepts of Compression Springs

Compression springs are mechanical devices that store energy when compressed. They are designed to resist forces applied along their axis, returning to their original length when the force is removed. These springs are widely used in various applications, including automotive and industrial machinery, to absorb shock, maintain pressure, and ensure smooth operation of mechanical components 1.

Role of the 179836 Compression Spring in Truck Operation

The 179836 Compression Spring plays a specific role in the operation of commercial trucks by providing the necessary force in various mechanical systems. It is often used in suspension systems, valve trains, and other components where consistent force application is required. The spring helps in absorbing shocks, maintaining pressure, and ensuring the smooth functioning of these systems.

Key Features of the 179836 Compression Spring

The 179836 Compression Spring is characterized by its robust material composition, typically made from high-quality steel alloys. Its design specifications include precise coil diameter, wire diameter, and free length, ensuring it meets the demanding requirements of commercial truck applications. Unique characteristics such as corrosion resistance and high load-bearing capacity enhance its performance and longevity 2.

Benefits of Using the 179836 Compression Spring

Using the 179836 Compression Spring offers several benefits. It contributes to improved reliability by ensuring consistent performance under varying conditions. Its durability allows for prolonged use with minimal maintenance. Additionally, the spring enhances the efficiency of truck operations by providing stable and reliable force application in critical mechanical systems.

Installation and Integration

Proper installation and integration of the 179836 Compression Spring are crucial for optimal performance. It should be installed according to manufacturer guidelines, ensuring it is correctly positioned within the mechanical system. Attention to detail during installation helps prevent issues such as misalignment or excessive wear, contributing to the spring’s longevity and effectiveness.

Troubleshooting Common Issues

Common issues with the 179836 Compression Spring may include signs of wear, such as deformation or corrosion. Regular inspections can help identify these issues early. Potential malfunctions might result in reduced performance of the mechanical system. Recommended solutions include replacing the spring if significant wear is detected and ensuring proper lubrication and maintenance of surrounding components.

Maintenance Tips

To ensure the longevity and efficient operation of the 179836 Compression Spring, regular maintenance is necessary. This includes routine inspections for signs of wear or damage, ensuring proper lubrication of surrounding components, and replacing the spring if it shows significant signs of degradation. Adhering to these maintenance practices helps maintain the spring’s performance and extends its service life.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history spanning over a century, Cummins is renowned for its high-quality and reliable products. The company’s extensive product range and strong reputation in the commercial truck industry underscore the quality and reliability of the 179836 Compression Spring 3.

Compression Spring (Part 179836) Compatibility with Cummins Engines

The Compression Spring part number 179836, manufactured by Cummins, is a crucial component designed to fit seamlessly within various Cummins engine models. This spring is engineered to provide the necessary compression force required for the smooth operation of these engines.

K19 and K38 Engines

In the K19 and K38 engines, the Compression Spring 179836 plays a vital role in maintaining the integrity of the engine’s internal components. These engines, known for their robust performance, benefit from the precise compression and tension control provided by this spring. It ensures that the engine’s valves and other moving parts operate within the specified parameters, enhancing overall engine efficiency and longevity.

K50 and L10 MECHANICAL Engines

For the K50 and L10 MECHANICAL engines, the Compression Spring 179836 is equally essential. These engines, which are part of Cummins’ lineup of high-performance diesel engines, require a spring that can withstand the demanding conditions of heavy-duty operations. The spring’s design allows it to absorb and distribute the forces generated during the engine’s operation, thereby reducing wear and tear on critical components.

Grouping of Engines

When considering the K19, K38, K50, and L10 MECHANICAL engines together, it is evident that the Compression Spring 179836 is a versatile component. Its ability to fit and function effectively across these different engine types underscores its importance in the Cummins engine ecosystem. This compatibility ensures that technicians and mechanics can confidently use this spring across various engine models, simplifying maintenance and repair processes.

Role of Part 179836 Compression Spring in Engine Systems

The part 179836 Compression Spring is integral to the efficient operation of several engine components, ensuring optimal performance and reliability.

In the context of calibration, the Compression Spring assists in maintaining consistent pressure levels, which is essential for accurate fuel delivery and combustion efficiency. This consistency is vital for the engine’s overall performance and longevity.

When integrated with the fuel pump, the Compression Spring helps in regulating the pressure within the fuel system. This regulation ensures that the fuel pump operates within its specified parameters, thereby enhancing its durability and effectiveness.

The interaction between the Compression Spring and the fuel pump code (such as CPL205) is particularly noteworthy. The spring’s role in modulating pressure directly influences the fuel pump’s performance, as indicated by the code. Proper pressure modulation ensures that the fuel pump code reflects optimal operating conditions, leading to efficient fuel delivery.

Furthermore, the Compression Spring plays a significant role in the fuel code system. By maintaining stable pressure, it ensures that the fuel code accurately represents the fuel system’s status, aiding in diagnostics and maintenance.

Conclusion

The 179836 Compression Spring is a critical component in the operation of commercial trucks and Cummins engines. Its robust design, compatibility with various engine models, and role in maintaining consistent pressure and force application contribute to the overall efficiency and reliability of truck and engine systems. Regular maintenance and proper installation are essential to ensure the longevity and performance of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.