This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

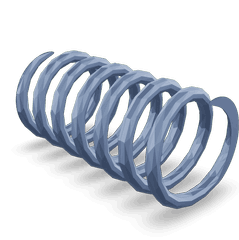

The Cummins 3002055 Compression Spring is a component designed for use in commercial truck operations. It serves a specific function within the truck’s mechanical systems, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance can help fleet managers and technicians maintain optimal truck performance.

Basic Concepts of Compression Springs

Compression springs are mechanical devices that store energy when compressed. They are widely used in various applications due to their ability to absorb shock, maintain pressure, and return to their original shape once the compressive force is removed. In mechanical systems, compression springs play roles in cushioning impacts, maintaining tension, and ensuring the proper functioning of moving parts 1.

Role of the 3002055 Compression Spring in Truck Operation

This Cummins part is integral to the operation of commercial trucks. It is designed to work within the truck’s mechanical systems, where it helps to absorb vibrations and shocks that occur during operation. By doing so, it contributes to the smooth running of the truck and helps protect other components from excessive wear and damage 2.

Key Features of the 3002055 Compression Spring

The 3002055 Compression Spring is characterized by several key features that enhance its performance. It is made from high-quality materials that provide durability and resistance to corrosion. The design specifications of the spring, including its coil diameter, wire diameter, and free length, are tailored to meet the specific demands of commercial truck applications. These features ensure that the spring can withstand the rigors of heavy-duty use while maintaining its functional integrity 3.

Benefits of Using the 3002055 Compression Spring

Incorporating this part into truck operations offers several benefits. Its robust construction and precise engineering contribute to improved reliability and durability. The spring’s ability to absorb shocks and vibrations leads to enhanced efficiency in truck operations, reducing the likelihood of component failure and extending the lifespan of the vehicle.

Installation and Integration

Proper installation and integration of the 3002055 Compression Spring are vital for ensuring optimal performance and longevity. Technicians should follow manufacturer guidelines when installing the spring, paying close attention to alignment and securing it within the truck’s mechanical systems. Correct installation ensures that the spring functions as intended, providing the intended benefits to the truck’s operation.

Common Issues and Troubleshooting

Like any mechanical component, this Cummins part may encounter issues over time. Common problems include spring fatigue, corrosion, and misalignment. Troubleshooting these issues involves inspecting the spring for signs of wear or damage, ensuring it is properly aligned, and addressing any corrosion with appropriate treatments. Regular maintenance can help prevent these issues from arising.

Maintenance Practices

To ensure continued reliable performance, the 3002055 Compression Spring should be subject to regular maintenance practices. This includes periodic inspections to check for signs of wear, corrosion, or misalignment. Replacement guidelines should be followed to ensure that the spring is replaced before it reaches the end of its service life, maintaining the efficiency and reliability of the truck’s mechanical systems.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established itself as a trusted name in the automotive and heavy-duty truck industries. The company’s expertise in manufacturing automotive components, including the 3002055 Compression Spring, underscores its dedication to providing reliable and high-performance solutions for commercial vehicle operators.

Compression Spring Part 3002055 in Cummins Engines

The Compression Spring part 3002055, manufactured by Cummins, is a critical component in several of their engine models. This spring is designed to provide the necessary force to maintain the engine’s operational integrity and efficiency.

K50 Engines

In the K50 engines, the Compression Spring part 3002055 plays a pivotal role in the valve train system. It ensures that the valves remain tightly closed during the compression and power strokes, preventing any potential leaks that could compromise engine performance. The spring’s design allows it to withstand the high pressures and temperatures within the engine, ensuring durability and reliability.

L10 MECHANICAL Engines

For the L10 MECHANICAL engines, the Compression Spring part 3002055 is integral to the fuel injection system. This spring helps maintain the correct pressure and timing in the fuel injectors, which is crucial for efficient combustion and power output. The spring’s ability to return to its original shape after compression ensures consistent fuel delivery, contributing to the engine’s overall performance and longevity.

N14 MECHANICAL Engines

In the N14 MECHANICAL engines, the Compression Spring part 3002055 is utilized in the turbocharger system. Here, it assists in maintaining the proper tension and alignment of the turbocharger components. This ensures that the turbocharger operates smoothly and efficiently, providing the necessary boost to enhance engine performance. The spring’s resilience under high-stress conditions is vital for the longevity and reliability of the turbocharger system.

By integrating the Compression Spring part 3002055 into these engines, Cummins ensures that each component operates within its designed parameters, contributing to the overall efficiency and durability of the engine.

Role of Part 3002055 Compression Spring in Engine Systems

The part 3002055 Compression Spring is integral to the efficient operation of several components within engine systems. Its primary function is to provide the necessary force to maintain the proper tension and alignment of moving parts, ensuring smooth and reliable performance.

Calibration

In the context of engine calibration, the 3002055 Compression Spring assists in maintaining consistent pressure and force on various sensors and actuators. This ensures that the engine control unit (ECU) receives accurate data, allowing for precise adjustments and optimal performance. The spring’s role in calibration helps in fine-tuning the engine’s parameters, leading to improved efficiency and reduced emissions.

Fuel Pump

Within the fuel pump system, the 3002055 Compression Spring is used to maintain the correct pressure within the fuel lines. It ensures that the fuel pump operates within its specified parameters, delivering the right amount of fuel to the engine under varying conditions. This consistent fuel delivery is essential for stable engine operation and performance.

Code and Fuel Code

When dealing with engine diagnostic codes, the 3002055 Compression Spring plays a part in ensuring that components related to fuel delivery and sensor readings function correctly. Any malfunction in these areas can trigger specific diagnostic trouble codes (DTCs). The spring’s reliable performance helps prevent such issues, contributing to a smoother diagnostic process and more accurate code readings.

Fuel Pump Code

In scenarios where the fuel pump code is triggered, the 3002055 Compression Spring’s role becomes even more apparent. It ensures that the fuel pump’s mechanical components, such as check valves and pressure regulators, operate within their design specifications. This helps in diagnosing and resolving fuel-related issues more effectively.

Fuel and Code Fuel

The interplay between fuel delivery and the diagnostic process is where the 3002055 Compression Spring shines. By maintaining the integrity of fuel system components, it ensures that the fuel supply is consistent and that any deviations are accurately reflected in the diagnostic codes. This integration is vital for both performance tuning and troubleshooting.

Conclusion

In summary, the 3002055 Compression Spring is a key component in various engine systems, contributing to the accurate calibration, reliable fuel delivery, and effective diagnostic processes. Its consistent performance ensures that engine components operate within their specified parameters, leading to overall improved engine efficiency and reliability.

-

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing.

↩ -

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩ -

Hu, H., Baseley, S. J., & Song, X. (2021). Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.