This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4014539 Compression Spring is a specialized component designed for use in commercial trucks. Manufactured by Cummins, a well-established name in the automotive industry, this part is integral to the efficient operation of truck mechanical systems. Understanding its role, features, and benefits can provide valuable insights into its importance in maintaining truck performance.

Basic Concepts of Compression Springs

Compression springs are mechanical devices that store energy when compressed. They are widely used in various mechanical systems due to their ability to absorb shock, maintain pressure, and return to their original shape once the compressive force is removed. These springs are crafted from materials that offer high elasticity and durability, ensuring they can withstand repeated use in demanding environments 1.

Purpose of the 4014539 Compression Spring in Truck Operation

The 4014539 Compression Spring plays a specific role in the operation of commercial trucks. It is designed to provide consistent pressure within the truck’s mechanical systems, ensuring smooth and reliable performance. This spring is often found in components where maintaining pressure or absorbing shock is necessary, contributing to the overall efficiency and longevity of the truck’s operation 2.

Key Features

The Cummins 4014539 Compression Spring is characterized by several key features that enhance its performance. It is made from high-quality materials, ensuring durability and resistance to wear. The design specifications of this spring are tailored to meet the demanding requirements of commercial truck applications, providing reliable performance under various operating conditions. Additionally, its unique attributes, such as precise coil spacing and optimal wire diameter, contribute to its effectiveness in truck mechanical systems 3.

Benefits

The use of the 4014539 Compression Spring in truck operations offers several benefits. Its high durability ensures long-term performance, reducing the need for frequent replacements. The reliability of this spring contributes to the overall efficiency of the truck, minimizing downtime and maintenance costs. Furthermore, its design enhances the truck’s operational efficiency by ensuring consistent pressure and shock absorption in critical components.

Installation and Usage

Proper installation of the 4014539 Compression Spring is crucial for its effective performance. It should be installed according to the manufacturer’s guidelines to ensure it functions as intended within the truck’s mechanical systems. Specific instructions may include ensuring the spring is correctly aligned and secured in place to prevent movement or damage during operation. Regular checks should be performed to ensure the spring remains in optimal condition.

Troubleshooting and Maintenance

Common issues with the 4014539 Compression Spring may include signs of wear, reduced performance, or failure to maintain pressure. Troubleshooting these issues involves inspecting the spring for physical damage, ensuring it is correctly installed, and checking for any obstructions that may affect its operation. Regular maintenance practices, such as cleaning and lubrication (if applicable), can help ensure the longevity and optimal performance of the spring.

Manufacturer: Cummins

Cummins is a reputable manufacturer known for producing high-quality automotive components. With a rich history in the industry, Cummins has established a strong reputation for reliability and innovation. Their commitment to quality is evident in the design and production of components like the 4014539 Compression Spring, ensuring they meet the high standards required for commercial truck applications.

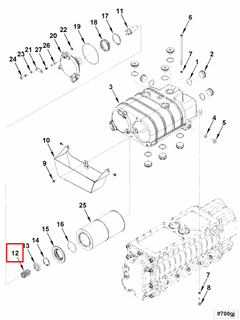

Role of Part 4014539 Compression Spring in Engine Systems

In the context of engine systems, the 4014539 Compression Spring is integral to the operation of various components, ensuring efficient and reliable performance. This spring is specifically designed to work within the assembly of the lubricating oil module, where it plays a significant role in maintaining the structural integrity and functionality of the system.

Within the Lubricating Oil Module Assembly, the compression spring assists in the proper seating and sealing of the Lubricating Oil Filter. It ensures that the filter is held firmly against the filter housing, preventing any bypass of unfiltered oil, which is essential for maintaining the cleanliness and viscosity of the engine oil.

In the Full Flow Oil Filter Assembly, the spring is responsible for applying consistent pressure to the filter media. This pressure is vital for the effective filtration of contaminants from the engine oil, ensuring that only clean oil circulates through the engine’s critical components.

The Filter Housing also benefits from the presence of the compression spring. It helps in maintaining a secure fit between the filter and the housing, which is crucial for the overall efficiency of the filtration process. The spring’s role becomes even more apparent in the Full Flow Assembly Filter, where it ensures that the filter element is correctly positioned and sealed, preventing any leakage or inefficient filtration.

Furthermore, in the Oil Filter Assembly Housing, the compression spring contributes to the durability and longevity of the assembly. It absorbs shocks and vibrations that occur during engine operation, protecting the filter and housing from potential damage.

In summary, the 4014539 Compression Spring is a key component in various engine oil filtration systems. Its role in ensuring proper filter seating, maintaining consistent pressure, and absorbing operational stresses is fundamental to the efficient and reliable operation of these systems.

Conclusion

The Cummins 4014539 Compression Spring is a vital component in the operation of commercial trucks and various engine systems. Its design and features ensure consistent pressure, shock absorption, and reliable performance, contributing to the overall efficiency and longevity of the truck and engine operations. Proper installation, maintenance, and understanding of its role are essential for maximizing its benefits and ensuring optimal performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.