This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

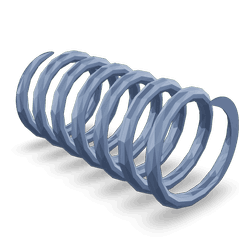

The Cummins 4349743 Compression Spring is a specialized component designed for use in heavy-duty truck operations. Its purpose is to provide necessary force and support within the truck’s mechanical systems, ensuring efficient and reliable performance. This spring is integral to maintaining the functionality and durability of various truck components.

Basic Concepts of Compression Springs

Compression springs are mechanical devices that store energy when compressed. They are designed to resist compressive forces and return to their original length when the force is removed. These springs are widely used in various mechanical systems for their ability to absorb shock, maintain pressure, and provide consistent force. Their applications range from automotive components to industrial machinery, making them versatile in many fields 1.

Role of the 4349743 Compression Spring in Truck Operations

The 4349743 Compression Spring plays a specific role in the operation of heavy-duty trucks by providing the necessary force and support in various mechanical systems. It is often used in suspension systems, valve trains, and other components where consistent force and reliable performance are required. The spring helps in absorbing shocks, maintaining pressure, and ensuring smooth operation of the truck’s mechanical parts 2.

Key Features of the 4349743 Compression Spring

The design and construction of the 4349743 Compression Spring include several key features that enhance its performance and durability. These features include its material composition, typically made from high-quality steel for strength and resilience, its coil diameter which determines the spring’s rate and load capacity, its wire diameter which affects the spring’s strength and flexibility, and its free length which is the length of the spring when not under compression. These characteristics ensure that the spring can withstand the rigors of heavy-duty truck operations 3.

Benefits of Using the 4349743 Compression Spring

The advantages provided by the 4349743 Compression Spring include enhanced durability, reliability, and performance in truck operations. Its high-quality construction ensures long-lasting use, while its precise design allows for consistent force application. This results in improved efficiency and reduced maintenance needs, making it a valuable component for heavy-duty trucks.

Installation and Integration

Proper installation and integration of the 4349743 Compression Spring into truck mechanical systems are crucial for ensuring optimal performance. Specific procedures should be followed to ensure the spring is correctly positioned and secured. This may include using appropriate tools and following manufacturer guidelines to avoid damage and ensure the spring functions as intended.

Troubleshooting Common Issues

Common problems associated with compression springs in truck operations can include spring failure, misalignment, and reduced performance. Troubleshooting steps may involve inspecting the spring for signs of wear or damage, ensuring it is correctly installed, and replacing it if necessary. Regular checks and maintenance can help identify and address these issues before they lead to more significant problems.

Maintenance Tips

Regular maintenance of the 4349743 Compression Spring is important to ensure its longevity and optimal performance. This includes routine inspections for signs of wear, corrosion, or damage. Replacement guidelines should be followed to ensure the spring is replaced before it fails. Additionally, keeping the spring clean and free from debris can help maintain its performance and extend its lifespan.

Cummins: A Brief Overview

Cummins Inc. is a well-established company with a strong reputation in the heavy-duty truck industry. Founded in 1919, Cummins has a long history of producing high-quality engines and components. Their product range includes engines, filtration systems, and aftermarket parts, all designed to meet the demanding needs of heavy-duty applications. Cummins is known for its commitment to innovation, quality, and customer satisfaction, making it a trusted name in the industry.

Compression Spring 4349743 Compatibility with Cummins Engines

The Compression Spring part number 4349743, manufactured by Cummins, is designed to fit seamlessly within the specified engine models. This part is integral to the engine’s operation, ensuring optimal performance and reliability.

QSK95 Engines

The Compression Spring 4349743 is compatible with the following QSK95 engine variants:

- QSK95 CM2350 K111

- QSK95 CM2350 K113

In these engines, the compression spring plays a crucial role in maintaining the integrity of the engine’s internal components. It ensures that the engine’s parts are held together under high pressure, preventing any potential misalignment or failure during operation.

Installation and Functionality

When installed in the QSK95 engines, the compression spring works in conjunction with other mechanical parts to provide a balanced and efficient engine performance. Its design allows it to withstand the rigors of continuous operation, ensuring longevity and reliability.

Importance of Proper Fitment

Proper fitment of the Compression Spring 4349743 is essential for the overall health of the engine. Any deviation from the specified design can lead to performance issues, increased wear, and potential engine failure. Therefore, it is crucial to use the correct part number for each engine model to maintain optimal engine function.

Maintenance and Replacement

Regular maintenance checks should include inspecting the compression spring for any signs of wear or damage. Timely replacement of the spring, if necessary, will help in preventing unexpected engine downtime and ensure the engine operates at peak efficiency.

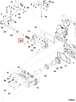

Role of Part 4349743 Compression Spring in Engine Systems

The part 4349743 Compression Spring is integral to the operation of several engine components, particularly those involved in the lubrication system.

In the Lubricating Oil Pump, the compression spring works in tandem with the pump’s internal mechanisms to ensure consistent and reliable oil flow. It helps maintain the necessary pressure for the pump to draw oil from the sump and deliver it to various engine parts, ensuring they remain well-lubricated and operate smoothly.

When considering the Lubricating Oil Pump Kit, the inclusion of the compression spring is essential. This kit often contains multiple components designed to work together to enhance the pump’s efficiency. The spring ensures that the pump can handle varying oil viscosities and temperatures, contributing to the overall reliability of the lubrication system.

In a broader sense, within the Pump assembly, the compression spring assists in regulating the mechanical movements that drive oil circulation. Its role is to provide the necessary force to keep the pump’s components in optimal working condition, thereby prolonging the pump’s lifespan and ensuring consistent performance.

The Lubricating Oil itself benefits from the efficient operation of the pump, which is partly dependent on the compression spring. Proper lubrication is vital for reducing friction and wear on moving parts, and the spring’s function ensures that the oil is delivered under the right conditions.

Lastly, in a Service Kit for engine maintenance, the compression spring is often a key replacement part. Its condition can significantly affect the pump’s performance, and including a high-quality spring in the service kit ensures that the pump can be restored to its original efficiency during maintenance procedures.

Conclusion

The Cummins 4349743 Compression Spring is a critical component in heavy-duty truck operations, ensuring the efficient and reliable performance of various mechanical systems. Its high-quality construction, precise design, and compatibility with specific Cummins engines make it an essential part for maintaining the durability and functionality of heavy-duty trucks. Regular maintenance and proper installation are key to maximizing the benefits of this component.

-

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ -

Mom, G. (2023). The Evolution of Automotive Engineering: A Handbook. SAE International.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2019). Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.