This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

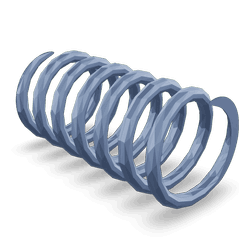

The Cummins 5255746 Compression Spring is a specialized component designed for use in commercial trucks. Its primary function is to provide necessary force and support within various mechanical systems of the truck. This spring is integral to ensuring the smooth operation and reliability of the truck’s components, contributing to overall performance and longevity.

Basic Concepts of Compression Springs

Compression springs are mechanical devices that store energy when compressed. They are designed to resist compressive forces and return to their original shape once the force is removed. These springs are widely used in various mechanical systems due to their ability to absorb shock, maintain pressure, and provide consistent force. In automotive and heavy-duty applications, compression springs play a significant role in suspension systems, engine components, and other areas 1.

Purpose of the Cummins 5255746 Compression Spring

This Cummins part serves a specific role in the operation of commercial trucks. It is designed to provide consistent force and support within the truck’s mechanical systems. This spring is often used in applications where reliable force application is required, such as in valve trains, suspension systems, and other components that undergo repetitive motion or stress. By maintaining proper tension and support, the spring ensures that these systems operate efficiently and reliably.

Key Features

The 5255746 Compression Spring is characterized by several key features that enhance its performance. It is typically made from high-quality materials such as spring steel, which offers excellent durability and resistance to fatigue. The spring’s design specifications, including its coil diameter, wire diameter, and number of coils, are precisely engineered to meet the demands of commercial truck applications. Additionally, the spring may feature unique attributes such as corrosion-resistant coatings or specialized end configurations to improve its functionality and longevity.

Benefits

This part provides several benefits that contribute to the overall performance and reliability of commercial trucks. Its high-quality material composition ensures durability and resistance to wear, while its precise design specifications guarantee consistent force application. The spring’s ability to withstand repetitive stress and maintain performance over time enhances the efficiency and reliability of the truck’s mechanical systems. Furthermore, the spring’s corrosion-resistant properties help protect it from environmental factors, ensuring long-term performance 2.

Installation and Usage

Proper installation of this Cummins part is crucial to ensure optimal performance and longevity. Before installation, it is important to verify that the spring is the correct size and type for the specific application. The installation process should follow manufacturer guidelines to ensure that the spring is properly seated and secured. Any prerequisites, such as cleaning the installation area or lubricating the spring, should be adhered to for best results. Special considerations, such as avoiding over-compression during installation, are also important to prevent damage to the spring.

Troubleshooting and Maintenance

Regular maintenance and troubleshooting are important to ensure the longevity and optimal performance of this part. Common issues may include spring fatigue, corrosion, or improper seating. Regular inspections should be conducted to check for signs of wear or damage. If any issues are detected, the spring should be replaced or repaired as necessary. Maintenance practices, such as keeping the spring clean and free from debris, can help prevent premature failure and ensure consistent performance.

Common Applications

This part is commonly used in various applications within commercial trucks. Typical applications include valve trains, where the spring provides necessary force to open and close valves, and suspension systems, where it helps absorb shock and maintain ride quality. The spring may also be used in other mechanical systems that require consistent force application and reliable performance.

Safety Considerations

When handling and installing this part, it is important to observe safety considerations to prevent injury and ensure proper installation. Potential hazards include spring breakage or sudden release of stored energy, which can cause injury. Precautions such as wearing protective gloves and eyewear, using proper tools, and following manufacturer guidelines can help mitigate these risks. Additionally, ensuring that the work area is clean and free from obstructions can help prevent accidents during installation.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and aftermarket parts. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the commercial truck industry. The company’s extensive product range and commitment to customer satisfaction have made it a trusted name among fleet operators and maintenance professionals.

Compatibility with Cummins Engines

This part, manufactured by Cummins, is designed to fit seamlessly with a range of Cummins engines. Here is a detailed look at its compatibility across various engine models:

ISF2.8 Engines

The Compression Spring is compatible with the following ISF2.8 engine variants:

- ISF2.8 CM2220 F117

- ISF2.8 CM2220 F129

These engines benefit from the spring’s ability to provide consistent compression, ensuring smooth operation and longevity of the engine components.

QSF2.8 Engines

The Compression Spring is also suitable for the following QSF2.8 engine models:

- QSF2.8 CM2880 F104

- QSF2.8 CM2880 F105

- QSF2.8 CM2880 F108

- QSF2.8 CM2880 F114

These engines, which are part of the QSF2.8 series, rely on the spring’s durability and precision to maintain optimal performance levels.

R2.8 Engine

Additionally, the Compression Spring is designed to fit the R2.8 engine:

- R2.8 CM2220 R101B

This engine variant also leverages the spring’s properties to ensure reliable and efficient engine function.

Summary

The Compression Spring by Cummins is a versatile component that enhances the performance of various ISF2.8, QSF2.8, and R2.8 engine models. Its compatibility with these engines underscores its importance in maintaining the operational efficiency and longevity of Cummins engines.

Role of Part 5255746 Compression Spring in Engine Systems

This part is an integral component in the efficient operation of several engine systems. Its primary function is to maintain consistent pressure and ensure smooth operation within these systems.

In the Engine Oil Cooler system, the compression spring works in conjunction with the valve mechanisms to regulate the flow of oil. This ensures that the oil is evenly distributed and maintains optimal temperature, which is essential for the longevity and performance of the engine.

Within the Front Cover assembly, the compression spring assists in the operation of various mechanical components. It helps in the precise movement of parts, ensuring that they function within their designed parameters, thus contributing to the overall reliability of the engine.

In the Lubricating Oil Cooler Module, the spring plays a role in the modulation of oil flow. By providing the necessary pressure, it ensures that the oil cooler operates efficiently, maintaining the oil at the correct temperature for effective lubrication.

The Lubricating Oil Pump also benefits from the presence of the compression spring. It aids in the consistent delivery of oil by ensuring that the pump components move smoothly and reliably. This consistent oil delivery is vital for the protection of engine components from wear and tear.

Lastly, in the Oil Cooler system, the compression spring is instrumental in maintaining the pressure required for efficient cooling. It ensures that the oil is cooled to the appropriate temperature before it is circulated back into the engine, thus playing a significant role in the engine’s thermal management 3.

Conclusion

The Cummins 5255746 Compression Spring is a critical component in the operation of commercial trucks and Cummins engines. Its design, featuring high-quality materials and precise engineering, ensures consistent force application and reliable performance across various mechanical systems. Proper installation, regular maintenance, and adherence to safety considerations are essential to maximize the benefits of this part. Its compatibility with a range of Cummins engines further highlights its importance in maintaining the operational efficiency and longevity of these engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.