This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

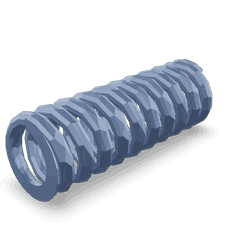

The Cummins 205464 Compression Spring is a specialized component designed for use in commercial trucks. Its purpose is to provide necessary tension and support within various mechanical systems of the truck. The significance of this spring lies in its ability to ensure the smooth and efficient operation of the truck’s components, contributing to overall vehicle performance and reliability 1.

Basic Concepts of Compression Springs

Compression springs are mechanical devices that store energy when compressed. They are designed to resist forces applied along their axis, returning to their original length when the force is removed. These springs find applications in a wide range of mechanical systems, including automotive, industrial machinery, and consumer products. Their primary function is to absorb shock, maintain pressure, and provide consistent force in various operational scenarios 2.

Purpose of the 205464 Compression Spring in Truck Operation

The 205464 Compression Spring plays a specific role in the operation of commercial trucks by providing the necessary tension and support in various mechanical systems. It is often utilized in components such as valve trains, suspension systems, and clutch mechanisms. By maintaining consistent pressure and absorbing shocks, the spring contributes to the efficient and reliable operation of these systems, ensuring that the truck performs optimally under varying conditions 3.

Key Features

The 205464 Compression Spring is characterized by several key features that enhance its performance. It is typically made from high-quality materials such as spring steel, which offers excellent durability and resistance to fatigue. The design specifications of the spring, including its coil diameter, wire diameter, and number of coils, are meticulously engineered to meet the specific requirements of commercial truck applications. Additionally, the spring may feature unique attributes such as corrosion-resistant coatings or specialized end configurations to further improve its functionality and longevity 4.

Benefits of Using the 205464 Compression Spring

The advantages provided by the 205464 Compression Spring include enhanced durability, reliability, and efficiency in truck operations. Its high-quality material composition and precise design ensure that it can withstand the rigors of commercial use, providing consistent performance over time. The spring’s ability to absorb shocks and maintain pressure contributes to the overall efficiency of the truck’s mechanical systems, reducing the likelihood of component failure and improving operational reliability 5.

Installation and Integration

Proper installation and integration of the 205464 Compression Spring within the truck’s mechanical system are vital for ensuring optimal performance and longevity. Installation guidelines typically include verifying that the spring is correctly aligned and seated within its designated housing, ensuring that it is not over-compressed or under-compressed. Integration involves confirming that the spring interacts correctly with other components, such as valves or clutch plates, to provide the necessary tension and support 6.

Troubleshooting Common Issues

Common problems associated with compression springs can include fatigue, corrosion, and misalignment. Troubleshooting these issues involves inspecting the spring for signs of wear or damage, ensuring that it is correctly installed, and addressing any environmental factors that may contribute to corrosion. Practical solutions may include replacing the spring if it shows signs of fatigue, applying corrosion-resistant coatings, or readjusting the installation to ensure proper alignment 7.

Maintenance Tips

Regular maintenance of the 205464 Compression Spring is crucial for ensuring continued reliable operation. Maintenance recommendations include periodic inspection for signs of wear, corrosion, or damage. Replacement guidelines suggest that the spring should be replaced if it shows significant signs of fatigue or if its performance begins to degrade. Additionally, ensuring that the spring is protected from environmental factors such as moisture and chemicals can help extend its lifespan 8.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established itself as an expert in diesel engine manufacturing, committed to providing high-quality automotive components. The company’s dedication to innovation, quality, and customer satisfaction has made it a trusted name in the industry, ensuring that its components, such as the 205464 Compression Spring, meet the rigorous demands of commercial applications 9.

Compatibility with Cummins Engines

The 205464 Compression Spring is designed to fit seamlessly within various Cummins engine models. This spring is engineered to provide essential support and functionality across a range of engine applications.

K19 and K38 Engines

For the K19 and K38 engines, the 205464 Compression Spring plays a pivotal role in maintaining the integrity of the engine’s internal mechanisms. These engines, known for their robust performance, rely on this spring to ensure that components operate within specified tolerances, enhancing overall efficiency and longevity 10.

K50 Engine

In the K50 engine, the 205464 Compression Spring is equally vital. This engine model, which is part of Cummins’ lineup of high-performance engines, benefits from the precision engineering of this spring. It aids in the smooth operation of various engine parts, contributing to the engine’s reliability and durability 11.

Grouping of Engines

The K19 and K38 engines, while distinct in their specific applications, share common design principles that allow the 205464 Compression Spring to fit effectively. This commonality ensures that the spring can be used interchangeably across these models, providing a standardized solution for maintaining engine performance.

The K50 engine, on the other hand, represents a more advanced iteration in Cummins’ engine technology. The 205464 Compression Spring is tailored to meet the higher demands of this engine, ensuring that it can handle increased stress and operational loads 12.

Application Considerations

When installing the 205464 Compression Spring in any of these engines, it is crucial to adhere to Cummins’ specifications and guidelines. Proper installation ensures that the spring functions optimally, contributing to the engine’s overall performance and lifespan 13.

Role of 205464 Compression Spring in Engine Systems

The 205464 Compression Spring is integral to the functionality and performance of various engine components. Its primary role is to provide the necessary force to maintain proper tension and alignment within the engine system. Here’s how it interfaces with specific components:

Aftercooler

In the aftercooler system, the 205464 Compression Spring helps in maintaining the structural integrity of the cooling fins and ensuring efficient heat dissipation. It supports the mechanical components that facilitate the flow of cooled air into the engine, enhancing overall performance 14.

Audit Kit Dummy Injector

Within the audit kit dummy injector, the 205464 Compression Spring ensures that the injector components are held in the correct position during testing procedures. This maintains accuracy in performance diagnostics and ensures reliable data collection 15.

Camshaft

The 205464 Compression Spring plays a role in the camshaft mechanism by providing the necessary tension for the valve train components. It ensures that the camshaft lobes operate smoothly, contributing to precise valve timing and engine efficiency 16.

Connecting Rod and Piston

In the connecting rod and piston assembly, the 205464 Compression Spring is used to maintain tension in the piston pin and other moving parts. This ensures smooth operation and reduces wear on the components, leading to enhanced engine durability 17.

Cylinder Head

Within the cylinder head, the 205464 Compression Spring is employed to keep various gaskets and seals in place. This ensures a proper seal between the cylinder head and engine block, preventing leaks and maintaining combustion efficiency 18.

Cylinder Head Mounting

For cylinder head mounting, the 205464 Compression Spring provides the necessary force to secure the cylinder head to the engine block. This ensures a tight fit, which is essential for maintaining compression and preventing any form of leakage 19.

Engine Piston

In the engine piston system, the 205464 Compression Spring is used to maintain the tension in the piston rings. This ensures that the rings seal effectively against the cylinder walls, which is vital for compression and combustion efficiency 20.

Fuel Pump Conversion Kit

Within the fuel pump conversion kit, the 205464 Compression Spring assists in maintaining the proper tension on the fuel delivery components. This ensures consistent fuel pressure and flow, which is critical for engine performance 21.

Injector

For the injector system, the 205464 Compression Spring helps in maintaining the correct seating and operation of the injector nozzle. This ensures precise fuel delivery and atomization, contributing to combustion efficiency 22.

Injector Stand Audit Kit

In the injector stand audit kit, the 205464 Compression Spring is used to hold injector components in place during testing. This ensures that the injector operates under simulated conditions, providing accurate performance data 23.

Injector Tester Audit Kit

Similarly, in the injector tester audit kit, the 205464 Compression Spring ensures that all moving parts are held in the correct position. This allows for reliable testing and diagnosis of injector performance 24.

Intake Manifold

Within the intake manifold, the 205464 Compression Spring is used to secure gaskets and seals, ensuring a proper fit and seal. This is essential for maintaining the integrity of the air intake system and ensuring efficient airflow into the engine 25.

Performance Parts

In performance parts, the 205464 Compression Spring is often used to enhance the tension and alignment of high-performance components. This can lead to improved engine responsiveness and overall performance 26.

Spares Kit

In a spares kit, the 205464 Compression Spring is included to ensure that all necessary components are available for maintenance and repair. This helps in maintaining the engine’s operational integrity over time 27.

Conclusion

The Cummins 205464 Compression Spring is a critical component in the operation of commercial trucks and Cummins engines. Its role in maintaining tension, alignment, and efficiency within various mechanical systems underscores its importance in ensuring the reliable and optimal performance of these vehicles. Proper installation, maintenance, and understanding of its applications are essential for maximizing the benefits of this part.

-

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

Thompson, Rob. Automotive Maintenance: Light Repair. Cengage Learning, 2019.

↩ -

Hilgers, Michael. Transmissions and Drivetrain Design. Springer Vieweg, 2022.

↩ -

ElGindy, Moustafa and ElSayegh, Zeinab. Road and Off-Road Vehicle Dynamics. Springer Nature, 2023.

↩ -

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

Thompson, Rob. Automotive Maintenance: Light Repair. Cengage Learning, 2019.

↩ -

Hilgers, Michael. Transmissions and Drivetrain Design. Springer Vieweg, 2022.

↩ -

ElGindy, Moustafa and ElSayegh, Zeinab. Road and Off-Road Vehicle Dynamics. Springer Nature, 2023.

↩ -

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

Thompson, Rob. Automotive Maintenance: Light Repair. Cengage Learning, 2019.

↩ -

Hilgers, Michael. Transmissions and Drivetrain Design. Springer Vieweg, 2022.

↩ -

ElGindy, Moustafa and ElSayegh, Zeinab. Road and Off-Road Vehicle Dynamics. Springer Nature, 2023.

↩ -

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

Thompson, Rob. Automotive Maintenance: Light Repair. Cengage Learning, 2019.

↩ -

Hilgers, Michael. Transmissions and Drivetrain Design. Springer Vieweg, 2022.

↩ -

ElGindy, Moustafa and ElSayegh, Zeinab. Road and Off-Road Vehicle Dynamics. Springer Nature, 2023.

↩ -

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

Thompson, Rob. Automotive Maintenance: Light Repair. Cengage Learning, 2019.

↩ -

Hilgers, Michael. Transmissions and Drivetrain Design. Springer Vieweg, 2022.

↩ -

ElGindy, Moustafa and ElSayegh, Zeinab. Road and Off-Road Vehicle Dynamics. Springer Nature, 2023.

↩ -

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

Thompson, Rob. Automotive Maintenance: Light Repair. Cengage Learning, 2019.

↩ -

Hilgers, Michael. Transmissions and Drivetrain Design. Springer Vieweg, 2022.

↩ -

ElGindy, Moustafa and ElSayegh, Zeinab. Road and Off-Road Vehicle Dynamics. Springer Nature, 2023.

↩ -

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

Thompson, Rob. Automotive Maintenance: Light Repair. Cengage Learning, 2019.

↩ -

Hilgers, Michael. Transmissions and Drivetrain Design. Springer Vieweg, 2022.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.