This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

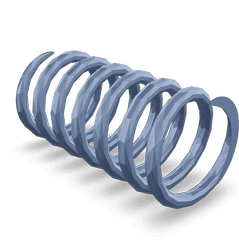

The Cummins 3004754 Compression Spring is a specialized component designed for use in heavy-duty truck operations. This spring plays a significant role in ensuring the efficient functioning of various mechanical systems within the truck. Understanding its purpose and significance is vital for maintaining optimal truck performance and reliability.

Basic Concepts of Compression Springs

Compression springs are mechanical devices that store energy when compressed. They are widely used in various applications due to their ability to exert a force when released. These springs are typically made from coiled metal and function by resisting compressive forces, returning to their original shape once the force is removed. In mechanical systems, compression springs are utilized for a variety of purposes, including cushioning, maintaining pressure, and facilitating the return motion of components 1.

Role of the 3004754 Compression Spring in Truck Operation

The Cummins 3004754 Compression Spring is integral to the truck’s mechanical system, particularly in applications where consistent and reliable force is required. This spring interacts with other components to ensure smooth operation and efficient energy transfer. Its role includes providing necessary pressure, absorbing shocks, and ensuring the proper functioning of interconnected parts within the truck’s system 2.

Key Features

The Cummins 3004754 Compression Spring is characterized by several key features that enhance its performance. It is constructed from high-quality materials, ensuring durability and reliability under demanding conditions. The design specifications of this spring are tailored to meet the specific requirements of heavy-duty truck applications, providing optimal performance and longevity. Unique attributes such as precise coil spacing and robust construction contribute to its effectiveness 3.

Benefits of Using the 3004754 Compression Spring

Utilizing the Cummins 3004754 Compression Spring offers several advantages. Its high-quality construction ensures improved durability, reducing the need for frequent replacements. The reliable performance of this spring contributes to the overall efficiency of the truck’s mechanical system. Additionally, its design enhances the stability and consistency of the system, leading to better overall truck operation 4.

Installation and Integration

Proper installation and integration of the Cummins 3004754 Compression Spring are crucial for ensuring its effective functioning within the truck’s system. Guidelines for installation include careful alignment with other components and securing it in place to prevent movement. Best practices involve following manufacturer recommendations and conducting thorough inspections to avoid potential issues. Challenges may arise from incorrect installation, highlighting the importance of precise handling and attention to detail 5.

Troubleshooting and Maintenance

Common issues related to the Cummins 3004754 Compression Spring can be addressed through systematic troubleshooting. Regular inspections for signs of wear or damage are recommended to ensure optimal performance. Maintenance tips include cleaning the spring and its surrounding components, checking for proper alignment, and replacing the spring if significant wear is detected. These practices help maintain the spring’s effectiveness and prolong its service life 6.

Performance Under Various Conditions

The Cummins 3004754 Compression Spring is designed to perform reliably under a range of operating conditions. It can withstand varying temperatures, loads, and environments, making it suitable for heavy-duty truck applications. Its robust construction ensures consistent performance, even in challenging conditions, contributing to the overall reliability of the truck’s mechanical system 7.

Comparative Analysis

When compared to similar components from other manufacturers, the Cummins 3004754 Compression Spring demonstrates competitive performance, durability, and cost-effectiveness. Its high-quality construction and precise design specifications position it as a reliable choice for heavy-duty truck applications. This spring’s ability to meet or exceed industry standards makes it a valuable component in ensuring the efficient operation of truck mechanical systems 8.

Cummins: A Brief Overview

Cummins Inc. is a renowned manufacturer in the heavy-duty truck industry, known for its wide range of high-quality products. With a rich history of innovation and excellence, Cummins has established a strong reputation for producing reliable and efficient components. The company’s product range includes engines, filtration systems, and various mechanical parts, all designed to meet the demanding requirements of heavy-duty applications. Cummins’ commitment to quality and performance is evident in its comprehensive offerings and continued industry leadership 9.

Compression Spring 3004754 Compatibility with Cummins Engines

The Compression Spring part number 3004754, manufactured by Cummins, is designed to fit seamlessly within a variety of Cummins engines. This spring is engineered to provide the necessary compression force required for optimal engine performance. Below is a detailed look at how this part integrates with specific Cummins engines.

K19 and L10 MECHANICAL Engines

The Compression Spring 3004754 is compatible with the K19 and L10 MECHANICAL engines. These engines are known for their robust design and reliability, often used in heavy-duty applications. The spring ensures that the engine components maintain the correct tension, which is crucial for the smooth operation of the engine’s internal mechanisms.

NH/NT 855 Engines

The NH/NT 855 engines also benefit from the Compression Spring 3004754. These engines are part of the Cummins lineup that is widely used in agricultural and construction machinery. The spring’s design allows it to withstand the high-stress environments these engines operate in, ensuring longevity and consistent performance.

V28 Engines

The V28 engine is another model where the Compression Spring 3004754 is a perfect fit. This engine is known for its power and efficiency, often used in various industrial applications. The spring’s role in the V28 engine is to maintain the precise compression needed for the engine’s valves and other moving parts, contributing to the engine’s overall efficiency and durability.

By ensuring that the Compression Spring 3004754 is correctly installed in these engines, users can expect enhanced performance, reliability, and longevity of their engine components.

Role of Part 3004754 Compression Spring in Engine Systems

In the realm of engine systems, the part 3004754 Compression Spring is instrumental in ensuring the smooth operation of several key components. This spring is primarily integrated into the fuel system, where it plays a significant role in maintaining the desired fuel pressure and flow.

Fuel Pump Operation

The Compression Spring is a vital component in the fuel pump assembly. It works in conjunction with the pump’s diaphragm or piston to regulate the fuel flow. By providing the necessary tension, the spring ensures that the fuel pump can effectively draw fuel from the tank and deliver it to the engine at the required pressure. This consistent fuel delivery is essential for the engine’s performance and efficiency.

Calibration and Fuel Code Management

In modern engine systems, precise calibration is necessary to optimize performance and meet emissions standards. The Compression Spring contributes to this by helping maintain the correct fuel pressure, which is a critical parameter in the engine’s calibration process. Additionally, it assists in managing the fuel code, ensuring that the engine control unit (ECU) receives accurate data regarding fuel delivery. This data is vital for the ECU to make real-time adjustments to the fuel injection timing and quantity.

Governor Maximum Spring Function

The Compression Spring also plays a role in the governor maximum (gov max) system. This system is designed to limit the engine’s speed to a safe maximum. The spring helps in modulating the governor’s response, ensuring that the engine does not exceed its speed limits under any condition. This is particularly important in high-performance engines where precise control over speed is necessary to prevent damage and ensure longevity.

Code Fuel Integration

In engines equipped with code fuel systems, the Compression Spring is integral to the operation of the code fuel mechanism. This system uses a series of codes to regulate fuel delivery based on various operating conditions. The spring ensures that the code fuel system can respond quickly and accurately to changes in engine load, throttle position, and other variables, thereby enhancing the engine’s overall performance and fuel efficiency.

Spring Governor Maximum System

Finally, the Compression Spring is a key component in the spring governor maximum system. This system uses a spring-loaded mechanism to control the engine’s speed by modulating the fuel supply. The Compression Spring provides the necessary tension to ensure that the governor can effectively regulate the fuel flow, maintaining the engine’s speed within the desired range. This is particularly important in applications where consistent engine speed is crucial, such as in industrial machinery and automotive applications.

Conclusion

In summary, the Cummins 3004754 Compression Spring is a fundamental component in various engine systems, contributing to the efficient and reliable operation of fuel pumps, calibration processes, fuel code management, and governor systems. Its role in these components underscores the importance of precision engineering in achieving optimal engine performance.

-

Hilgers, Michael. Chassis and Axles. Springer Vieweg, 2023.

↩ -

Hilgers, Michael. Electrical Systems and Mechatronics, Second Edition. Springer Vieweg, 2023.

↩ -

Halderman, James D. Automotive Principles: Diagnosis and Service. Prentice Hall, 2012.

↩ -

Caines, Arthur J., Haycock, Roger F., & Hillier, John E. Automotive Lubricants Reference Book. SAE International, 2004.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 5504548, QSM11 CM876 M101.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 5504548, QSM11 CM876 M101.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 5504548, QSM11 CM876 M101.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 5504548, QSM11 CM876 M101.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 5504548, QSM11 CM876 M101.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.