3030803

Compression Spring

Cummins®

AVAILABLE

2 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3030803 Compression Spring is a specialized component designed for use in commercial truck operations. Its purpose is to provide necessary tension and support within various mechanical systems of the truck. The significance of this spring lies in its ability to enhance the reliability and efficiency of truck operations, contributing to smoother and more dependable performance 4.

Basic Concepts of Compression Springs

Compression springs are mechanical devices that store energy when compressed. They function by resisting compressive forces, which allows them to return to their original shape once the force is removed. These springs are widely used in various mechanical systems for their ability to absorb shock, maintain pressure, and provide consistent force. Their applications range from automotive components to industrial machinery, making them vital in many engineering solutions 1.

Role of the 3030803 Compression Spring in Truck Operation

The Cummins 3030803 Compression Spring plays a specific role in the operation of a commercial truck by providing the necessary tension and support in various mechanical systems. It is often found in components such as suspension systems, where it helps absorb shocks and vibrations, ensuring a smoother ride. Additionally, it may be used in engine components to maintain proper tension and alignment, contributing to the overall efficiency and reliability of the truck’s operation 2.

Key Features

The Cummins 3030803 Compression Spring is characterized by several key features that enhance its performance. It is typically made from high-quality materials such as spring steel, which provides durability and resistance to wear. The design specifications of this spring, including its coil diameter, wire diameter, and free length, are meticulously engineered to meet the demanding requirements of commercial truck applications. Unique attributes such as corrosion resistance and fatigue life further contribute to its reliability and longevity 4.

Benefits of Using the 3030803 Compression Spring

The advantages of using the Cummins 3030803 Compression Spring include enhanced durability, reliability, and efficiency in truck operations. Its high-quality material composition ensures it can withstand the rigors of commercial use, while its precise design specifications guarantee consistent performance. The spring’s ability to maintain tension and support under varying conditions contributes to the overall efficiency and reliability of the truck’s mechanical systems 4.

Installation and Integration

Proper installation and integration of the Cummins 3030803 Compression Spring within a truck’s mechanical system are vital for ensuring optimal performance and longevity. Guidelines for installation include careful alignment with other components, ensuring there is no excessive force applied during compression, and verifying that the spring is securely positioned. Following these guidelines helps prevent premature wear and ensures the spring functions as intended within the truck’s system 2.

Troubleshooting and Maintenance

Common issues that may arise with compression springs include wear, fatigue, and loss of tension. Methods for troubleshooting these problems involve regular inspections for signs of damage or deformation, testing the spring’s ability to return to its original shape, and ensuring it maintains the required tension. Maintenance practices such as cleaning, lubrication, and periodic replacement can help ensure the longevity and effectiveness of the Cummins 3030803 Compression Spring 4.

Performance and Efficiency

The Cummins 3030803 Compression Spring contributes to the overall performance and efficiency of a commercial truck by providing consistent tension and support in critical mechanical systems. This enhances the truck’s ability to absorb shocks and vibrations, leading to improved ride comfort and reduced wear on other components. Additionally, the spring’s role in maintaining proper alignment and tension within engine components can contribute to better fuel efficiency and load-bearing capabilities 4.

Safety Considerations

Important safety considerations when using the Cummins 3030803 Compression Spring include proper handling, installation, and regular inspections. Ensuring the spring is correctly installed and maintained helps prevent accidents and ensures safe operation. Regular inspections for signs of wear or damage are crucial for identifying potential issues before they lead to failure. Additionally, following manufacturer guidelines for handling and installation helps ensure the spring functions safely and effectively within the truck’s system 2.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes a variety of components and systems designed to enhance the performance, reliability, and efficiency of commercial vehicles. Cummins’ commitment to quality is evident in its rigorous testing and quality control processes, ensuring that its products meet the highest standards of performance and durability 3.

Compression Spring 3030803 Compatibility with Cummins Engines

The Compression Spring part number 3030803, manufactured by Cummins, is a critical component in various Cummins engine models. This spring is designed to provide the necessary compression force in the engine’s valve train, ensuring smooth and reliable operation.

G855 and NH/NT 855 Engines

The Compression Spring 3030803 is compatible with the G855 and NH/NT 855 engines. These engines are known for their robust design and high performance, often used in heavy-duty applications. The spring’s role in these engines is to maintain the correct valve clearance, ensuring efficient combustion and reducing wear on the valve components 3.

N14 CELECT and N14 MECHANICAL Engines

For the N14 CELECT and N14 MECHANICAL engines, the Compression Spring 3030803 is equally essential. These engines are widely used in various industries, including construction and transportation. The spring helps in maintaining the valve timing and pressure, which is crucial for the engines’ performance and longevity 3.

QSNT14 CM876 N102 Engine

The QSNT14 CM876 N102 engine also benefits from the Compression Spring 3030803. This engine model is designed for high-performance applications, and the spring plays a vital role in ensuring that the valves operate correctly under high-stress conditions. The precise compression force provided by the spring helps in achieving optimal engine efficiency and reliability 3.

Role of Part 3030803 Compression Spring in Engine Systems

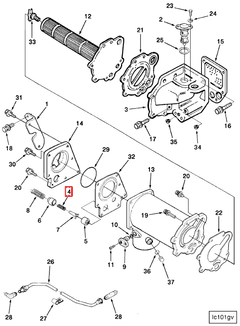

The 3030803 Compression Spring is an essential component in various engine systems, contributing to the efficient operation and maintenance of several critical functions.

In the cooler engine oil system, the compression spring aids in maintaining consistent pressure, ensuring that the oil is effectively cooled before it is recirculated through the engine. This is particularly important in high-performance engines where oil temperature management is vital for longevity and efficiency 4.

Within the cooler lubricating oil filter assembly, the 3030803 spring helps in regulating the flow of oil through the filter media. By providing the necessary tension, it ensures that the filter elements remain in optimal position, enhancing filtration efficiency and prolonging the filter’s service life 4.

In the EBM: Cooler (Engine Block Mounted Cooler), the compression spring plays a role in the mechanical operation of the cooler, assisting in the consistent flow of oil through the cooling passages. This ensures that the oil maintains an appropriate temperature, which is essential for engine protection 4.

The engine oil cooler system benefits from the 3030803 spring by ensuring that the cooling process is smooth and uninterrupted. The spring helps in maintaining the structural integrity of the cooler, preventing leaks and ensuring efficient heat exchange 4.

In the filter/cooler lub oil system, the spring is integral to the operation of the bypass valve. It ensures that the valve functions correctly under varying pressure conditions, allowing for safe operation even when the filter becomes clogged 4.

The lub oil cooler and lub oil filter cooler assemblies utilize the compression spring to maintain the proper tension on the filter elements. This ensures that the oil is effectively filtered and cooled, reducing the risk of contaminants reaching the engine components 4.

In the full flow oil filter system, the spring ensures that the filter media is held firmly in place, maximizing the filtration efficiency and protecting the engine from harmful particles 4.

The lub oil filter and lube oil cooler systems also rely on the 3030803 spring to ensure that the filter elements are correctly positioned and that the cooling process is efficient. This is vital for maintaining the quality of the lubricating oil and ensuring optimal engine performance 4.

In the lubricating oil cooler (top level assembly), the spring assists in the mechanical operation of the cooler, ensuring that the oil is effectively cooled before it is returned to the engine 4.

The lubricating oil cooler conversion kit and lubricating oil cooler kit incorporate the compression spring to ensure that the cooler components function correctly, providing reliable cooling performance 4.

In the lubricating oil filter and lubricating oil filter and cooler systems, the spring ensures that the filter elements are held in place, enhancing filtration efficiency and protecting the engine from contaminants 4.

The oil cooler system utilizes the compression spring to maintain the structural integrity of the cooler, ensuring efficient heat exchange and consistent oil temperature 4.

The oil cooler cover mounting system benefits from the spring by ensuring that the cover is securely held in place, preventing leaks and ensuring the cooler operates efficiently 4.

In the oil cooler engine and oil cooler lubricating systems, the spring ensures that the cooling process is smooth and uninterrupted, protecting the engine from overheating 4.

The oil filter and cooler system relies on the compression spring to maintain the proper tension on the filter elements, ensuring effective filtration and cooling 4.

The pressure sensing switch and sensing bypass valve systems incorporate the spring to ensure that these components function correctly under varying pressure conditions, providing reliable engine protection 4.

Conclusion

The Cummins 3030803 Compression Spring is a critical component in the operation and maintenance of commercial trucks and Cummins engines. Its role in providing necessary tension and support within various mechanical systems enhances the reliability, efficiency, and performance of these vehicles. Proper installation, regular maintenance, and adherence to safety guidelines are essential for ensuring the longevity and effectiveness of this part. Cummins’ commitment to quality and innovation is reflected in the design and functionality of the 3030803 Compression Spring, making it a valuable asset in the commercial truck industry.

-

Jazar, Reza N. Vehicle Dynamics: Theory and Application. Springer, 2017.

↩ -

Cummins Inc. Owners Manual. Bulletin Number 5612930.

↩ ↩ ↩ -

Gifford, Clive. Cars Encyclopedia. DK Publishing, 2014.

↩ ↩ ↩ ↩ -

Duffy, Owen C., and Gus Wright. Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning, 2016.

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.