3053157

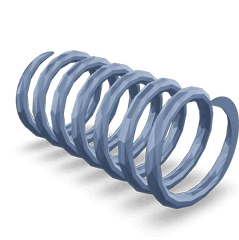

Compression Spring

Cummins®

AVAILABLE

2 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3053157 Compression Coil Spring is a specialized component designed for use in heavy-duty trucks. Its purpose is to support the vehicle’s suspension system, ensuring efficient load handling and contributing to ride comfort. Given the demanding conditions under which heavy-duty trucks often operate, the role of such components is significant for maintaining vehicle performance and durability 3.

Basic Concepts of Compression Coil Springs

Compression coil springs are mechanical devices that store energy when compressed. They are widely used in automotive systems for their ability to absorb shock and maintain structural integrity under load. These springs function by resisting compressive forces, which allows them to return to their original shape once the force is removed. Their applications in automotive systems range from suspension components to engine mounting systems 1.

Role of the 3053157 Compression Coil Spring in Truck Operation

The 3053157 Compression Coil Spring plays a specific role in the suspension system of heavy-duty trucks. It is designed to support the weight of the vehicle and its cargo, absorbing shocks from the road to provide a smoother ride. By effectively managing the forces exerted on the truck during operation, this spring contributes to both the stability of the vehicle and the comfort of its occupants 3.

Key Features of the 3053157 Compression Coil Spring

The design and construction of the 3053157 Compression Coil Spring include several notable features. It is made from high-quality materials that offer durability and resistance to wear. The coil diameter and the number of coils are engineered to provide optimal load-bearing capacity, ensuring the spring can handle the significant weights associated with heavy-duty truck operations. Additionally, the spring’s construction allows for efficient energy absorption and release, contributing to its performance under heavy loads 2.

Benefits of Using the 3053157 Compression Coil Spring

The advantages of using the 3053157 Compression Coil Spring include enhanced durability, reliable performance under heavy loads, and longevity. Its design ensures it can withstand the rigors of heavy-duty truck use, providing consistent support and shock absorption. This contributes to the overall efficiency and safety of the vehicle, reducing the need for frequent replacements and maintenance 3.

Installation and Integration

Proper installation of the 3053157 Compression Coil Spring within the truck’s suspension system is crucial for its effective operation. Installation guidelines recommend ensuring the spring is correctly aligned and secured to prevent any movement that could lead to damage or reduced performance. Special considerations may include checking for any signs of wear on mounting points and ensuring the spring is compatible with the truck’s suspension system 3.

Maintenance and Troubleshooting

Regular maintenance practices for the 3053157 Compression Coil Spring include inspecting it for signs of wear or damage, ensuring it remains clean and free from debris that could affect its performance. Common issues that may arise include reduced spring efficiency or physical damage to the coils. Troubleshooting steps may involve checking the spring’s alignment, inspecting for corrosion, and ensuring it is properly lubricated if required 3.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive industry, particularly in the segment of heavy-duty truck components. The company’s product range includes a variety of engine and component solutions designed to meet the demanding requirements of heavy-duty applications 3.

Compatibility of 3053157 with Cummins Engines

The Compression Coil Spring, part number 3053157, manufactured by Cummins, is designed to fit seamlessly with several Cummins engine models, ensuring optimal performance and reliability. Below is a detailed overview of its compatibility with specific engine types.

K19 and K50 Engines

The Compression Coil Spring is compatible with both the K19 and K50 engines. These engines are known for their robust design and are often used in heavy-duty applications. The spring’s design ensures it can withstand the high pressures and stresses encountered in these engines, providing consistent performance over time 3.

M11 CELECT PLUS and M11 MECHANICAL Engines

The Compression Coil Spring is also suitable for the M11 CELECT PLUS and M11 MECHANICAL engines. These engines are part of Cummins’ M11 series, which is renowned for its versatility and efficiency. The spring’s compatibility with these models ensures that it can handle the specific demands of these engines, contributing to their overall reliability and longevity 3.

N14 MECHANICAL Engine

The N14 MECHANICAL engine is another model that benefits from the Compression Coil Spring. This engine is widely used in various industries due to its durability and power. The spring’s design is tailored to meet the unique requirements of the N14 MECHANICAL engine, ensuring it can operate efficiently under different conditions 3.

NH/NT 855 Engines

Lastly, the Compression Coil Spring is compatible with the NH/NT 855 engines. These engines are known for their high performance and efficiency, making them a popular choice in many applications. The spring’s design ensures it can handle the stresses and pressures associated with these engines, providing reliable performance and durability 3.

Role of 3053157 Compression Coil Spring in Engine Systems

The 3053157 Compression Coil Spring is integral to the efficient operation of various engine components. It primarily functions to maintain consistent pressure and ensure smooth operation within the engine system.

Fuel System Integration

In the fuel system, the Compression Coil Spring works in conjunction with the fuel pump. It helps in regulating the pressure of the fuel as it is pumped from the tank to the engine. This consistent pressure is vital for the fuel injectors to deliver the correct amount of fuel into the combustion chamber, ensuring optimal fuel-air mixture for combustion 3.

Calibration and Fuel Codes

The spring also plays a role in the calibration of the fuel system. Accurate calibration is necessary for the engine to operate efficiently under various conditions. The Compression Coil Spring assists in maintaining the precise pressure levels required for the fuel system, which is often indicated by specific fuel codes. These codes are part of the engine’s diagnostic system and help in identifying any discrepancies in fuel delivery or pressure 3.

Interaction with Fuel Pump Code

When dealing with the fuel pump code, the Compression Coil Spring ensures that the fuel pump operates within its designed parameters. The spring’s ability to compress and expand helps in stabilizing the fuel flow, which is essential for the fuel pump to function correctly. This stability is particularly important when the engine is under load or during rapid acceleration, where fuel demand fluctuates 3.

Fuel Base and Overall System Harmony

At the fuel base, where the fuel is stored before injection, the Compression Coil Spring contributes to maintaining a stable fuel environment. This stability is crucial for the overall harmony of the engine system, as it ensures that the fuel is ready for immediate and efficient combustion when required 3.

Conclusion

The 3053157 Compression Coil Spring is a vital component in both the suspension and engine systems of heavy-duty trucks. Its role in supporting the vehicle’s load, absorbing shocks, and maintaining consistent pressure within the engine system underscores its importance in ensuring vehicle performance, durability, and reliability. Proper installation, maintenance, and understanding of its compatibility with various engine models are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.