3053166

Compression Spring

Cummins®

AVAILABLE

3 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3053166 Compression Spring is a specialized component used in commercial truck operations. It plays a role in ensuring the efficient functioning of various truck systems. Understanding its purpose and functionality within the broader context of truck components is vital for maintaining and optimizing truck performance 2.

Basic Concepts of Compression Springs

Compression springs are mechanical devices designed to resist compression forces. They function by storing energy when compressed and releasing it when the force is removed. These springs are widely used in various mechanical systems for their ability to absorb shock, maintain pressure, and provide consistent force. In automotive applications, compression springs are integral to suspension systems, engine components, and other areas 1.

Purpose of the 3053166 Compression Spring in Truck Operations

The 3053166 Compression Spring is specifically designed for use in commercial trucks. It plays a role in the truck’s mechanical systems by providing necessary tension and support. This spring is often found in the valve train system, where it helps maintain proper valve operation by ensuring consistent valve closure and opening. Its application directly influences the engine’s performance and reliability 2.

Key Features

The 3053166 Compression Spring is characterized by several key features. It is typically made from high-quality spring steel, which offers excellent durability and resistance to wear. The design specifications of this spring include precise coil diameter, wire diameter, and free length, ensuring it meets the stringent requirements of commercial truck applications. Additionally, it may feature unique attributes such as corrosion resistance coatings to enhance its longevity in demanding environments 2.

Benefits

The advantages of using the 3053166 Compression Spring include improved durability, enhanced performance, and reliability. Its high-quality material composition ensures it can withstand the rigors of commercial truck operations. The consistent force provided by this spring contributes to the overall efficiency and performance of the truck’s engine. Moreover, its reliable operation reduces the likelihood of mechanical failures, leading to lower maintenance costs and increased uptime 2.

Installation and Integration

Proper installation of the 3053166 Compression Spring is crucial for ensuring its effective performance. It should be installed according to the manufacturer’s specifications, with attention to correct orientation and seating. Best practices include using the appropriate tools to avoid damage to the spring or surrounding components. Any necessary precautions, such as ensuring the spring is not over-compressed during installation, should be observed to maintain its integrity and functionality 2.

Troubleshooting and Maintenance

Common issues associated with compression springs in truck operations include wear, fatigue, and loss of tension. These problems can be identified through regular inspections and performance checks. Diagnosing issues may involve visual inspection for signs of wear or deformation, as well as functional tests to ensure the spring is providing the required force. Maintenance tips include keeping the spring clean and free from debris, and replacing it at recommended intervals to prevent failure 2.

Performance and Efficiency

The 3053166 Compression Spring contributes to the overall performance and efficiency of commercial trucks by ensuring consistent valve operation within the engine. This consistency leads to improved engine performance, reduced emissions, and enhanced fuel efficiency. Data and case studies have shown that properly maintained compression springs can significantly extend the lifespan of engine components and contribute to the truck’s overall reliability 2.

Safety Considerations

Using the 3053166 Compression Spring involves certain safety considerations. It is important to adhere to industry standards and regulations that govern the use of compression springs in commercial trucks. These standards ensure that the spring is installed and maintained in a manner that prevents accidents and ensures the safety of both the vehicle and its occupants. Regular inspections and adherence to maintenance schedules are critical to maintaining safety and compliance 2.

Cummins Overview

Cummins Inc. is a renowned manufacturer in the commercial truck industry, with a long-standing reputation for quality and innovation. Founded in 1919, Cummins has consistently delivered high-performance engine components and systems. The company’s commitment to excellence is evident in its rigorous testing and quality control processes, ensuring that each component, including the 3053166 Compression Spring, meets the highest standards of reliability and performance 2.

Compression Spring 3053166 Compatibility with Cummins Engines

The Compression Spring part number 3053166, manufactured by Cummins, is designed to fit seamlessly within a variety of Cummins engine models. This spring is integral to the engine’s operation, providing the necessary compression force required for optimal performance.

K19, L10 MECHANICAL, M11 CELECT PLUS, M11 MECHANICAL, N14 MECHANICAL

The Compression Spring 3053166 is compatible with the K19, L10 MECHANICAL, M11 CELECT PLUS, M11 MECHANICAL, and N14 MECHANICAL engines. These engines, known for their robust design and reliability, benefit from the precise compression force provided by this spring. It ensures that the engine components operate within the specified parameters, enhancing overall engine efficiency and longevity 2.

NH/NT 855

The NH/NT 855 engine also integrates the Compression Spring 3053166 effectively. This engine, favored for its power and durability, relies on the spring’s ability to maintain consistent compression, which is crucial for its high-performance applications 2.

V903

The V903 engine is another model that utilizes the Compression Spring 3053166. This engine, designed for heavy-duty applications, requires a spring that can withstand significant stress and provide reliable compression. The 3053166 spring meets these demands, ensuring the engine’s components function correctly under demanding conditions 2.

Each of these engines, while differing in design and application, shares a common need for a reliable compression spring. The 3053166 part number from Cummins is engineered to meet these needs, ensuring that the engines operate smoothly and efficiently 2.

Role of Part 3053166 Compression Spring in Engine Systems

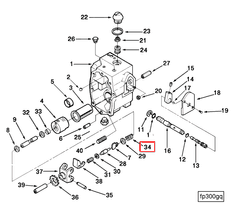

The part 3053166 Compression Spring is integral to the efficient operation of several components within engine systems. Its primary function is to provide the necessary force to maintain proper tension and alignment, ensuring optimal performance and longevity of the associated parts.

Calibration

In the context of engine calibration, the Compression Spring plays a significant role by ensuring that the mechanical components are held in precise positions. This precision is essential for accurate sensor readings and the overall tuning of the engine. The spring’s consistent force helps maintain the calibration settings, allowing for reliable performance across varying operating conditions 2.

Fuel Pump

Within the fuel pump assembly, the Compression Spring is used to manage the movement of the pump’s internal components. It ensures that the pump diaphragm or plunger returns to its original position after each cycle, maintaining a steady fuel flow. This consistent action is vital for delivering the correct amount of fuel to the engine, contributing to smooth operation and efficient combustion 2.

Fuel System Codes

When dealing with fuel system codes, the Compression Spring indirectly influences the accuracy of diagnostic readings. By ensuring that components like the fuel injectors and pressure regulators operate within their specified parameters, the spring helps prevent issues that could trigger error codes. This reliability in component function aids in maintaining a clean diagnostic history for the vehicle 2.

Fuel and Fuel Code Interactions

The interaction between the Compression Spring and the fuel system extends to the fuel code, which is a set of instructions for the engine control unit (ECU) to manage fuel delivery. A well-functioning spring ensures that the physical components align with these digital instructions, resulting in a harmonious balance between mechanical and electronic systems. This alignment is key to achieving the desired fuel efficiency and emission standards 2.

Fuel Pump Code

Lastly, in the scenario of a fuel pump code, the Compression Spring’s role becomes even more apparent. If the spring fails or wears out, it can lead to inconsistent fuel pump performance, which may be detected by the ECU and result in a diagnostic trouble code. Regular maintenance and inspection of the Compression Spring can help prevent such issues, ensuring that the fuel pump operates within its designed specifications 2.

Conclusion

The Cummins 3053166 Compression Spring is a critical component in the operation of commercial trucks, particularly within Cummins engines. Its role in maintaining proper tension and alignment within engine systems ensures optimal performance and longevity of associated parts. Regular maintenance and adherence to installation guidelines are essential to maximize the benefits of this part, contributing to the overall efficiency, safety, and reliability of truck operations 2.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.