This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3062415 Compression Spring is a specialized component designed for heavy-duty truck applications. It plays a role in ensuring the efficient operation of trucks by contributing to various mechanical systems. Understanding its function and importance can help in maintaining and optimizing truck performance.

Basic Concepts of Compression Springs

Compression springs are mechanical devices that store energy when compressed. They are widely used in various applications due to their ability to absorb shock, maintain pressure, and return to their original shape once the compressive force is removed. The principle behind compression springs involves the conversion of mechanical energy into potential energy, which is then released when the spring is allowed to expand 1.

Purpose of the 3062415 Compression Spring in Truck Operation

This Cummins part is integral to the truck’s mechanical systems, particularly in applications where consistent pressure and shock absorption are required. It helps in maintaining the integrity of the system by providing the necessary force to keep components in place and functioning correctly. This spring contributes to the overall functionality and performance of the truck by ensuring that mechanical parts operate within their designed parameters.

Key Features

This part is characterized by its high-quality material composition, typically made from durable steel alloys. Its design specifications include precise coil diameter, wire diameter, and free length, which are tailored to meet the specific demands of heavy-duty truck applications. These features enhance its performance and durability, making it a reliable component in demanding environments.

Benefits

Using this Cummins part offers several advantages. Its robust construction ensures improved reliability and enhanced performance. The spring’s durability leads to potential cost savings over time, as it requires less frequent replacement compared to lower-quality alternatives. Additionally, its efficient design contributes to the overall smoothness and effectiveness of the truck’s operation.

Installation and Integration

Proper installation of this part is crucial for optimal performance. It should be carefully fitted within the truck’s system, ensuring it interfaces correctly with other components. Following manufacturer guidelines during installation helps maintain the spring’s integrity and ensures it functions as intended. Correct installation is key to achieving the desired performance and longevity of the spring.

Troubleshooting and Maintenance

Identifying common issues with this part involves regular inspection for signs of wear, deformation, or damage. Diagnostic techniques may include visual checks and functional tests to ensure the spring is performing correctly. Maintenance practices such as cleaning and lubricating the spring can help prolong its lifespan. Knowing when to inspect and potentially replace the spring is important for consistent performance and safety.

Performance and Efficiency

This part contributes to the truck’s overall performance and efficiency by providing stable and consistent pressure within the mechanical systems. This stability can impact fuel consumption, load handling, and operational smoothness. By ensuring that components function correctly, the spring helps maintain the truck’s efficiency and reliability under various operating conditions.

Safety Considerations

The safety implications associated with this part include the importance of proper maintenance and timely replacement. Ensuring the spring is in good condition helps prevent potential hazards that could arise from component failure. Regular inspections and adherence to maintenance schedules are vital to avoid safety risks and maintain the truck’s operational integrity.

Cummins Corporation

Cummins Inc. is a renowned manufacturer with a rich history in the automotive and heavy-duty truck industry. The company is known for its wide range of high-quality components and its reputation for reliability and innovation. Cummins’ commitment to producing durable and efficient parts makes it a trusted source for automotive components, including the 3062415 Compression Spring 2.

Compatibility with Cummins Engines

The Compression Spring part number 3062415, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is integral to the engine’s operation, providing the necessary compression and tension required for optimal performance.

K19 Series

The K19 engine series benefits from the 3062415 Compression Spring, ensuring reliable performance and durability. This spring is engineered to withstand the specific demands of the K19 engine, enhancing its operational efficiency.

KTA19GC Series

The KTA19GC engines, including the KTA19GC CM558 variant, are compatible with the 3062415 Compression Spring. This part is crucial for maintaining the engine’s integrity and performance, particularly in demanding applications.

QSK19 Series

The QSK19 engines, which include models such as QSK19 CM2350 K105, QSK19 CM2350 K114, QSK19 CM2350 K144G, QSK19 CM500, and QSK19 CM850 MCRS, all utilize the 3062415 Compression Spring. This spring is designed to meet the rigorous standards of the QSK19 series, ensuring consistent performance across various models.

QSK19G Series

The QSK19G engine also integrates the 3062415 Compression Spring seamlessly. This part is essential for the engine’s functionality, providing the necessary compression and support for reliable operation.

Role of 3062415 Compression Spring in Engine Systems

Part 3062415, a Compression Spring, is integral to the functionality of various engine components. Its primary role is to provide the necessary force to maintain the proper operation and interaction between different parts.

Base Parts and Kits

In base parts and kits, the Compression Spring ensures that components remain in their designated positions and operate under the correct tension. This is particularly important in assemblies where parts need to move or engage with one another, such as in valve trains or clutch mechanisms. The spring’s consistent force helps in maintaining the integrity and performance of these assemblies over time.

Onboard Spares

When included in onboard spares, the Compression Spring serves as a reliable replacement for worn-out or damaged springs within the engine system. Its design allows for easy integration into existing systems, ensuring that the engine can continue to operate efficiently without significant downtime.

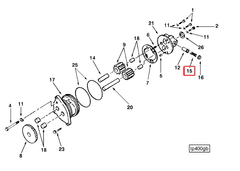

Lubricating Oil Pump

Within the lubricating oil pump, the Compression Spring plays a key role in maintaining the pump’s operational efficiency. It ensures that the pump components, such as the plunger or gears, return to their original position after each cycle. This consistent return motion is essential for the continuous flow of lubricating oil throughout the engine, preventing metal-to-metal contact and reducing wear.

Parts and Base

In broader terms, across various parts and the engine base, the Compression Spring assists in managing the mechanical stresses and movements. It helps in absorbing shocks and vibrations, thereby protecting other sensitive components from damage. This is particularly important in high-stress areas such as the crankshaft or camshaft bearings.

Pump and Lubricating Oil

Finally, in the context of pumps and lubricating oil systems, the Compression Spring ensures that the pump valves and other moving parts function smoothly. It aids in the precise control of oil flow, which is vital for maintaining optimal lubrication and cooling of engine components. This, in turn, enhances the overall durability and performance of the engine.

Conclusion

The Cummins 3062415 Compression Spring is a vital component in heavy-duty truck applications, contributing to the efficient operation and reliability of various mechanical systems. Its robust construction, precise design, and compatibility with multiple Cummins engines make it an essential part for maintaining optimal performance and safety in demanding environments.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.