3071915

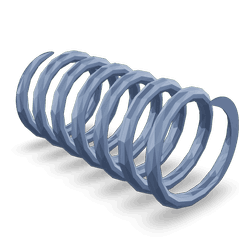

Compression Spring

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3071915 Compression Spring is a specialized component designed for use in heavy-duty truck operations. Its purpose is to provide necessary force and support within various mechanical systems of the truck. The significance of this compression spring lies in its ability to enhance the reliability and efficiency of the truck’s operations, ensuring smooth and consistent performance under demanding conditions 3.

Basic Concepts of Compression Springs

Compression springs are helical springs designed to resist compressive forces. When a load is applied, the spring compresses, storing potential energy. Upon removal of the load, the spring returns to its original shape, releasing the stored energy. These springs are widely used in mechanical systems for applications such as cushioning, maintaining pressure, and providing consistent force. Their design allows for efficient energy absorption and release, making them vital in various industrial and automotive applications 1.

Role of the 3071915 Compression Spring in Truck Operations

The Cummins 3071915 Compression Spring plays a specific role in the operation of heavy-duty trucks by providing necessary force and support within the truck’s mechanical systems. It is often used in components such as suspension systems, valve trains, and clutch mechanisms. In these applications, the spring helps maintain proper tension, absorb shocks, and ensure consistent operation of moving parts. Its function is integral to the overall performance and durability of the truck 4.

Key Features of the 3071915 Compression Spring

The Cummins 3071915 Compression Spring is characterized by its robust design and high-quality materials. Constructed from durable steel alloys, it offers excellent resistance to wear and fatigue. The spring’s precise coiling and tight tolerances ensure consistent performance under varying loads and conditions. Its design also includes features that enhance durability and reliability, making it suitable for the rigorous demands of heavy-duty truck operations 2.

Benefits of Using the 3071915 Compression Spring

The use of the Cummins 3071915 Compression Spring provides several advantages in truck operations. These include improved reliability due to its durable construction, enhanced efficiency through consistent force application, and increased longevity as a result of its resistance to wear and fatigue. The spring’s ability to maintain performance over time contributes to the overall effectiveness and cost-efficiency of the truck’s mechanical systems 3.

Installation and Integration

Proper installation of the Cummins 3071915 Compression Spring is crucial for ensuring optimal performance. It should be integrated within the truck’s mechanical systems according to manufacturer specifications. This includes ensuring correct alignment, proper seating, and secure fastening. Attention to these details during installation helps prevent issues such as misalignment, excessive wear, and reduced efficiency 4.

Troubleshooting and Maintenance

Identifying common issues related to the Cummins 3071915 Compression Spring involves regular inspection for signs of wear, deformation, or fatigue. Maintenance practices include cleaning the spring and its surrounding components, checking for proper tension, and replacing the spring if significant wear is detected. Troubleshooting tips for mechanics and fleet operators may involve analyzing the spring’s performance under load and addressing any inconsistencies or failures promptly 1.

Performance and Efficiency

The Cummins 3071915 Compression Spring contributes to the overall performance and efficiency of heavy-duty trucks by providing consistent force and support within critical mechanical systems. Its durable construction and precise design help maintain optimal operation, reducing the likelihood of failures and enhancing the truck’s reliability. Relevant data and case studies may demonstrate the spring’s positive impact on truck performance and longevity 2.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the automotive and heavy-duty truck industry. The company’s product range includes a variety of engines, components, and systems designed to meet the demanding needs of commercial and industrial applications. Cummins’ commitment to innovation, quality, and customer satisfaction has made it a trusted name in the industry 3.

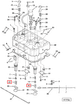

Compression Spring Part 3071915 in Cummins Engines

The Compression Spring part number 3071915, manufactured by Cummins, is integral to the operation of several Cummins engine models. This spring is designed to provide the necessary force to maintain the engine’s components in their correct positions, ensuring smooth and efficient operation.

N14 MECHANICAL Engines

In the N14 MECHANICAL engines, the Compression Spring 3071915 plays a crucial role in the valve train system. It helps to keep the valves closed under high-pressure conditions, ensuring that the engine maintains its performance and reliability. The spring’s design allows it to withstand the extreme conditions within the engine, providing consistent performance over time 3.

NH/NT 855 Engines

Similarly, in the NH/NT 855 engines, the Compression Spring 3071915 is used in the valve train system. This engine model, known for its durability and power, relies on the spring to maintain the integrity of the valve mechanism. The spring’s ability to compress and return to its original shape is vital for the engine’s ability to cycle through its operational phases efficiently 3.

Both engine models benefit from the precision engineering of the Compression Spring 3071915, ensuring that the engine components function correctly and reliably. The spring’s design and material properties are tailored to meet the specific demands of these engines, providing a critical component in the overall engine assembly 3.

Role of Part 3071915 Compression Spring in Engine Systems

The part 3071915 Compression Spring is integral to the functionality of various engine systems, particularly those involving braking mechanisms. In brake systems, this spring plays a significant role in ensuring the proper operation of the brake components. It aids in maintaining the necessary pressure within the system, which is essential for effective braking performance 4.

In the context of an engine brake kit, the 3071915 Compression Spring contributes to the modulation of brake force. It assists in the precise control of the brake application, which is vital for both safety and efficiency in vehicle operation. The spring’s role becomes even more pronounced in systems like the Cummins Engine Brake Kit, where it helps in managing the increased demands placed on the braking system due to the engine’s higher power output 4.

Furthermore, within an engine brake overhaul kit, the 3071915 Compression Spring is used to restore or enhance the braking system’s performance. It ensures that the overhauled system operates as efficiently as a new one, providing reliable braking under various driving conditions 4.

In slave piston kits, this compression spring is essential for the smooth operation of the pistons. It helps in maintaining the correct pressure and movement within the system, which is crucial for the consistent application of the brakes 4.

Overall, the 3071915 Compression Spring is a key component in ensuring the reliability and efficiency of engine and brake systems. Its proper function is essential for the safe and effective operation of these systems in various automotive applications 4.

Conclusion

The Cummins 3071915 Compression Spring is a critical component in heavy-duty truck operations, providing necessary force and support within various mechanical systems. Its robust design, high-quality materials, and precise engineering ensure consistent performance, enhanced reliability, and increased efficiency. Proper installation, regular maintenance, and timely troubleshooting are essential for maximizing the benefits of this Cummins part. The spring’s role in engine and brake systems underscores its importance in ensuring the safe and effective operation of heavy-duty trucks.

-

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ ↩ -

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩ ↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ ↩ ↩ ↩ ↩ ↩ -

Goodnight, N., & VanGelder, K. (2019). Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning.

↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.