This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

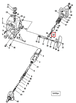

The Connection Bracket 3071951, manufactured by Cummins, is a component designed for use in commercial trucks. Cummins, a well-established name in the commercial truck industry, produces a range of engine and component parts that are integral to the functionality and efficiency of commercial vehicles. This part is significant within this context as it plays a role in connecting various components and systems within the truck, contributing to the overall performance and reliability of the vehicle.

Purpose and Functionality

The Connection Bracket 3071951 serves to facilitate the connection between different components and systems within a commercial truck. By providing a secure mounting point, it ensures that these components remain properly aligned and connected, which is vital for the efficient operation of the truck. This Cummins part is instrumental in maintaining the structural integrity of the truck’s systems, allowing for the smooth transfer of forces and ensuring that components function as intended.

Key Features

The Connection Bracket 3071951 is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials, which contribute to its strength and resistance to wear and tear. The design of the bracket includes specific elements that allow for easy installation and secure fastening. Additionally, it may feature unique characteristics such as corrosion-resistant coatings or specialized mounting points that further improve its functionality in demanding commercial truck environments.

Benefits

The advantages provided by the Connection Bracket 3071951 include improved structural integrity within the truck’s systems, which can lead to enhanced performance and reliability. Its design allows for ease of installation, reducing downtime during maintenance or repair procedures. Furthermore, by ensuring proper alignment and secure connection of components, the bracket contributes to the overall efficiency of the truck’s systems, potentially leading to better fuel economy and reduced maintenance costs over time.

Installation Process

Installing the Connection Bracket 3071951 involves several steps to ensure proper alignment and secure fastening. The process begins with identifying the correct location for the bracket on the truck. Once positioned, the bracket should be aligned with the components it is intended to connect. Using the appropriate tools and fasteners, the bracket is then securely attached. It is important to follow the manufacturer’s guidelines for torque specifications to ensure that the fasteners are tightened to the correct level, providing a secure connection without over-tightening, which could damage the bracket or the components it is connecting.

Maintenance Tips

To ensure the longevity and optimal performance of the Connection Bracket 3071951, routine maintenance practices should be followed. This includes periodic inspections to check for signs of wear, damage, or loose fasteners. Cleaning the bracket and its surrounding area can prevent the buildup of dirt and debris, which could affect its performance. Additionally, tightening any loose fasteners as part of regular maintenance can help maintain the secure connection of components, ensuring the continued efficient operation of the truck.

Troubleshooting Common Issues

Common problems that may arise with the Connection Bracket 3071951 include signs of wear or damage, loose fasteners, or misalignment of connected components. Troubleshooting these issues involves inspecting the bracket and its connections for any visible signs of damage or wear. Loose fasteners should be tightened according to the manufacturer’s specifications, and any misalignment of components may require re-positioning or re-securing the bracket. Recognizing these signs early can prevent more significant issues from developing, maintaining the efficiency and safety of the truck’s operation.

Compatibility and Applications

The Connection Bracket 3071951 is designed to be compatible with specific types of commercial trucks and engine models. Its applications vary depending on the truck’s configuration and setup, playing a role in connecting components in a manner that is tailored to the specific requirements of the vehicle. Understanding the compatibility of the bracket with the truck’s make and model is crucial for ensuring proper function and integration within the vehicle’s systems.

Safety Considerations

When working with the Connection Bracket 3071951, it is important to follow safety precautions and guidelines. This includes proper handling of the bracket and components, usage of personal protective equipment, and adherence to manufacturer recommendations for installation and maintenance. Ensuring that all fasteners are tightened to the correct specifications and that the bracket is securely installed can prevent accidents or injuries during the operation of the truck.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its high-quality engines and components. With a history of innovation and commitment to quality, Cummins offers a wide range of products designed to enhance the performance, efficiency, and reliability of commercial vehicles. The company’s reputation is built on its dedication to providing solutions that meet the demanding requirements of the commercial truck sector, ensuring that its components, like the Connection Bracket 3071951, contribute to the success and safety of commercial operations.

Compatibility with Cummins Engines

This part is compatible with several Cummins engine models, including the K38, K50, M11 CELECT PLUS, M11 MECHANICAL, and N14 MECHANICAL engines. Its design ensures that it can withstand the stresses and vibrations inherent in these engines, maintaining the integrity of the engine’s mounting system.

Role in Engine Systems

The Connection Bracket 3071951 is integral to the seamless operation of various engine components, ensuring efficient and reliable performance. This bracket facilitates the secure attachment of the fuel pump to the engine system, allowing for precise calibration and optimal fuel delivery.

When integrating the fuel pump into the engine, the Connection Bracket ensures that the pump is correctly aligned and firmly held in place. This alignment is essential for the accurate reading of the fuel code, which is a critical parameter for the engine’s fuel management system. The fuel code, derived from the fuel pump calibration, dictates the precise amount of fuel to be injected into the engine under various operating conditions.

The Connection Bracket also plays a role in maintaining the integrity of the fuel lines and connections. By providing a stable mounting point, it reduces the risk of fuel leaks and ensures that the fuel pump operates within its specified parameters. This stability is particularly important during engine calibration, where even minor deviations can affect engine performance and efficiency.

Furthermore, the bracket aids in the organization and management of wiring and sensor connections related to the fuel pump. This organization is vital for the accurate transmission of data between the fuel pump and the engine control unit (ECU). The ECU relies on this data to make real-time adjustments to the fuel injection process, ensuring that the engine runs smoothly and efficiently.

Conclusion

In summary, the Connection Bracket 3071951 is a versatile and essential component for several Cummins engine models, ensuring proper mounting and alignment across different engine types. Its role in maintaining the structural and functional integrity of the fuel delivery system is indispensable for overall engine performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.