This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

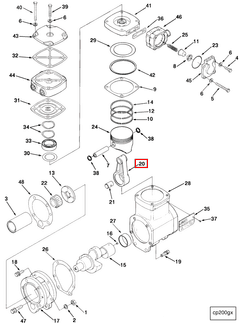

The Cummins 3011891 Compressor Connecting Rod is a specialized component designed for use in heavy-duty truck compressors. Its purpose is to facilitate the transfer of motion and force between the compressor’s crankshaft and piston, ensuring efficient operation of the compressor system. The significance of this component lies in its role in maintaining the mechanical integrity and performance of the compressor, which is vital for the overall functionality of the truck’s air system 1.

Function and Operation

The Compressor Connecting Rod operates within the compressor assembly by connecting the crankshaft to the piston. As the crankshaft rotates, the connecting rod translates this rotational motion into linear motion, driving the piston up and down within the compressor cylinder. This motion is fundamental to the compression process, where air is drawn in, compressed, and then discharged to supply the truck’s air brake system and other pneumatic components. The efficiency of this motion transfer directly impacts the compressor’s ability to generate the required pressure and volume of compressed air 2.

Key Features

The design and material characteristics of the 3011891 Compressor Connecting Rod are tailored to withstand the high stresses and dynamic loads encountered in heavy-duty applications. Constructed from high-strength materials, the connecting rod is engineered to offer durability and resistance to wear. Its design may include features such as precision machining for tight tolerances, which ensures smooth operation and minimal friction. Additionally, the connecting rod might incorporate heat treatment processes to enhance its strength and fatigue resistance, contributing to its longevity in demanding environments 3.

Role in Compressor Efficiency

The Compressor Connecting Rod plays a significant role in the overall efficiency and reliability of the truck’s compressor system. By ensuring a smooth and efficient transfer of motion from the crankshaft to the piston, it helps maintain the compressor’s operational performance. This component’s design and material properties contribute to reducing mechanical losses and enhancing the compressor’s ability to meet the truck’s air supply demands under various operating conditions 4.

Installation and Compatibility

Proper installation of the 3011891 Compressor Connecting Rod is crucial for ensuring the compressor’s optimal performance and longevity. Installation guidelines typically include verifying the rod’s alignment with the crankshaft and piston, ensuring all mating surfaces are clean and free of debris, and using the correct torque specifications for any fasteners. Compatibility with various Cummins compressor models is an important consideration, and specific installation requirements may vary depending on the compressor model. It is advisable to consult the manufacturer’s guidelines for detailed compatibility and installation instructions 5.

Maintenance and Troubleshooting

Routine maintenance practices for the Compressor Connecting Rod include regular inspections for signs of wear, damage, or excessive play. Lubrication, if applicable, should be checked and replenished according to the manufacturer’s recommendations to ensure smooth operation. Common issues that may arise include wear on the connecting rod bearings or fatigue cracks in the rod itself. Troubleshooting steps may involve inspecting the rod for visible damage, checking the clearances between the rod and crankshaft/piston, and assessing the condition of the bearings. Any detected issues should be addressed promptly to prevent further damage and ensure the compressor’s continued reliable operation 6.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history dating back to 1919, Cummins has established a strong reputation for quality, innovation, and reliability in the automotive and heavy-duty truck industries. The company’s commitment to excellence is evident in its comprehensive product range, which includes engines, powertrain components, and aftermarket parts designed to meet the demanding requirements of various applications. Cummins’ dedication to quality and innovation is reflected in the design and manufacturing of components like the 3011891 Compressor Connecting Rod, ensuring they meet the high standards expected in heavy-duty truck operations 7.

Compatibility of Compressor Connecting Rod Part 3011891 with Cummins Engines

The Compressor Connecting Rod part 3011891, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is integral to the engine’s operation, connecting the piston to the crankshaft and facilitating the conversion of linear motion into rotational motion. Below is a detailed description of the engines with which this part is compatible:

4B3.9 and 6B5.9 Engines

The 4B3.9 and 6B5.9 engines are part of Cummins’ B and 6B series, known for their robust performance and reliability in various applications. The Compressor Connecting Rod part 3011891 is specifically engineered to fit these engines, ensuring smooth operation and longevity.

6C8.3, B5.9 G, and C8.3 G Engines

The 6C8.3, B5.9 G, and C8.3 G engines are also part of Cummins’ lineup, offering a range of power outputs and configurations. The part 3011891 is compatible with these engines, providing the necessary strength and durability to withstand the demands of heavy-duty applications.

C GAS PLUS CM556 and QSB5.9 44 CM550 Engines

The C GAS PLUS CM556 and QSB5.9 44 CM550 engines are designed for specific applications, including agricultural and industrial uses. The Compressor Connecting Rod part 3011891 is engineered to fit these engines, ensuring optimal performance and reliability.

ISB CM550, ISC CM554, ISL CM554, ISM CM570, ISX CM570 Engines

The ISB, ISC, ISL, ISM, and ISX engines are part of Cummins’ Powertrain lineup, known for their versatility and efficiency. The part 3011891 is compatible with these engines, providing a critical link in the engine’s operation.

K19, K38, and K50 Engines

The K19, K38, and K50 engines are part of Cummins’ K series, designed for heavy-duty applications. The Compressor Connecting Rod part 3011891 is engineered to fit these engines, ensuring durability and performance in demanding environments.

L10 CELECT, L10 GAS, and L10 MECHANICAL Engines

The L10 CELECT, L10 GAS, and L10 MECHANICAL engines are part of Cummins’ L10 series, offering a range of configurations for various applications. The part 3011891 is compatible with these engines, providing the necessary strength and reliability.

M11 CELECT, M11 CELECT PLUS, and M11 MECHANICAL Engines

The M11 CELECT, M11 CELECT PLUS, and M11 MECHANICAL engines are part of Cummins’ M11 series, known for their efficiency and performance. The Compressor Connecting Rod part 3011891 is designed to fit these engines, ensuring smooth operation and longevity.

N14 CELECT, N14 CELECT PLUS, and N14 MECHANICAL Engines

The N14 CELECT, N14 CELECT PLUS, and N14 MECHANICAL engines are part of Cummins’ N14 series, offering a range of power outputs and configurations. The part 3011891 is compatible with these engines, providing the necessary strength and durability.

NH/NT 855 Engines

The NH/NT 855 engines are part of Cummins’ NH/NT series, designed for agricultural applications. The Compressor Connecting Rod part 3011891 is engineered to fit these engines, ensuring optimal performance and reliability.

This comprehensive compatibility ensures that the Compressor Connecting Rod part 3011891 is a versatile and reliable component for a wide range of Cummins engines 8.

Role of Part 3011891 Compressor Connecting Rod in Engine Systems

The part 3011891 Compressor Connecting Rod is integral to the efficient operation of various engine systems, particularly those involving air compressors and their associated components. This component facilitates the transfer of motion from the crankshaft to the piston within the cylinder of an air compressor.

In the context of a 1-Cylinder Air Compressor, the connecting rod ensures that the rotational motion of the Crankcase is effectively converted into the linear motion required to drive the piston. This motion is essential for compressing air within the cylinder, which is a fundamental function of the compressor.

When considering the Accessory Drive system, the connecting rod plays a role in maintaining the synchronization between the compressor’s moving parts and the engine’s crankshaft. This synchronization is vital for the consistent operation of the Air Compressor Drive and the overall efficiency of the Air Compressor Support and Drive mechanism.

In more complex setups, such as those involving a Compressor Conversion Kit or an Air Compressor Kit, the connecting rod’s function remains consistent: to ensure smooth and reliable transmission of motion. This is particularly important in systems where the compressor is part of a larger network, such as in Painted Air Compressor units or those integrated with Vacuum Pump Crankcase systems.

For systems utilizing specific head codes like Comp AR73659 to Head 1204 or Comp AR73807 Head 2420, the connecting rod’s role is to maintain the precise mechanical linkage required for optimal performance. This is essential in high-performance or specialized compressor applications where exact timing and motion transfer are paramount.

In summary, the part 3011891 Compressor Connecting Rod is a key component in various engine systems, ensuring the effective transfer of motion from the crankshaft to the piston, thereby facilitating the compression of air and the efficient operation of the compressor 9.

Conclusion

The Cummins 3011891 Compressor Connecting Rod is a critical component in the operation of heavy-duty truck compressors. Its design and material properties are tailored to withstand the demanding conditions of heavy-duty applications, ensuring durability, efficiency, and reliability. Proper installation, maintenance, and troubleshooting are essential to maximize the performance and longevity of this component. The compatibility of this part with a wide range of Cummins engines underscores its versatility and importance in the efficient operation of various engine systems.

-

Peters, G., & Peters, B. J. (2002). Automobile Vehicle Safety. CRC Press.

↩ -

Bari, S. (2013). Diesel Engine Combustion, Emissions and Condition Monitoring. InTech.

↩ -

Stiesch, G. (2003). Modeling Engine Spray and Combustion Processes. Springer Verlag.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 6314881.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 6314881.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 6314881.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 6314881.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 6314881.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.