This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3063644 Compressor Crankcase is a component designed for use in heavy-duty trucks. It plays a role in the compressor system, contributing to the efficient operation of the vehicle. This part is integral to maintaining the performance and reliability of the truck’s engine by ensuring the proper functioning of the compressor.

Basic Concepts of Compressor Crankcase

A compressor crankcase is a housing that encloses the rotating components of a compressor. Its primary function is to contain and protect these internal parts, which include the crankshaft, bearings, and other moving elements. The crankcase also plays a role in managing the lubrication system, ensuring that oil is distributed to critical areas to reduce friction and wear. Additionally, it contributes to the overall performance of the truck by maintaining the integrity of the compressor system and supporting efficient air compression 1.

Purpose of the 3063644 Compressor Crankcase

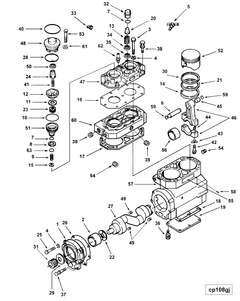

The 3063644 Compressor Crankcase is designed to house and protect the internal components of the compressor. It provides a secure environment for the crankshaft, bearings, and other rotating parts, shielding them from external contaminants and mechanical stress. This protection is vital for the longevity and performance of the compressor, as it helps to maintain the precision alignment and smooth operation of these components 2.

Key Features

The 3063644 Compressor Crankcase boasts several key features that enhance its functionality and durability. These include a robust construction that withstands the rigors of heavy-duty use, precise engineering to ensure optimal performance, and seamless integration with other compressor components. The design of the crankcase also facilitates efficient oil circulation, which is crucial for the lubrication and cooling of internal parts 3.

Benefits

The use of the 3063644 Compressor Crankcase offers several benefits. It contributes to improved reliability by protecting critical components from wear and damage. Enhanced performance is achieved through precise engineering and efficient lubrication. Additionally, the design of the crankcase helps to reduce maintenance requirements, making it a cost-effective solution for heavy-duty truck operators.

Installation Process

Installing the 3063644 Compressor Crankcase requires careful attention to detail. The process involves preparing the compressor for installation, ensuring that all mating surfaces are clean and free of debris. Proper alignment of the crankcase with the compressor is critical to ensure optimal performance. Necessary tools, such as torque wrenches and alignment tools, should be used to secure the crankcase in place and to make any required adjustments.

Common Issues and Troubleshooting

Common issues that may arise with the 3063644 Compressor Crankcase include leaks, cracks, or excessive wear. These problems can often be traced to improper installation, lack of maintenance, or operational stress. Troubleshooting these issues involves a thorough inspection of the crankcase and its seals, as well as an assessment of the compressor’s overall condition. Solutions may range from simple repairs, such as sealing a leak, to more complex procedures, like replacing worn components.

Maintenance Tips

Regular maintenance is key to ensuring the longevity and optimal performance of the 3063644 Compressor Crankcase. This includes routine inspections for signs of wear or damage, cleaning the crankcase to remove any accumulated debris, and checking the lubrication system to ensure proper oil circulation. Adhering to recommended inspection intervals and performing these maintenance practices can help prevent issues and extend the life of the compressor.

Manufacturer Information - Cummins

Cummins is a renowned manufacturer with a long-standing reputation in the industry for producing high-quality compressor components. The company’s commitment to innovation and quality is evident in the design and construction of the 3063644 Compressor Crankcase. Cummins’ expertise in engineering and manufacturing ensures that their products meet the demanding requirements of heavy-duty applications, providing reliable performance and durability.

Cummins Compressor Crankcase Part 3063644 Compatibility

The Cummins Compressor Crankcase part number 3063644 is designed to fit seamlessly with several engine models, ensuring optimal performance and reliability. This part is integral to the engine’s operation, providing a robust housing for the compressor components.

K19 Engines

The K19 engine series benefits from the precision engineering of the 3063644 compressor crankcase. This part is specifically tailored to the K19’s design, ensuring that it integrates smoothly with the engine’s other components. The K19 engines are known for their durability and efficiency, and the compressor crankcase plays a role in maintaining these qualities.

N14 MECHANICAL Engines

Similarly, the N14 MECHANICAL engines are compatible with the 3063644 compressor crankcase. This part is engineered to fit the unique specifications of the N14 MECHANICAL series, providing a reliable and sturdy housing for the compressor. The N14 MECHANICAL engines are recognized for their robust performance and longevity, and the compressor crankcase is a key component in achieving these attributes.

Grouping of Compatible Engines

While the 3063644 compressor crankcase is explicitly designed for the K19 and N14 MECHANICAL engines, it is important to note that Cummins’ engineering ensures compatibility across similar engine models within these series. This means that the part may also fit other variants or iterations of these engines, provided they share the same foundational design and specifications.

Role of Part 3063644 Compressor Crankcase in Engine Systems

The 3063644 Compressor Crankcase is an integral component in various engine systems, particularly those involving air compressors and accessory drives. Its primary function is to house and protect the internal components of the compressor, ensuring efficient operation and longevity of the system.

Integration with Air Compressor Systems

In air compressor systems, the Compressor Crankcase serves as the foundation for the compressor mechanism. It encloses the compressor’s moving parts, such as the pistons and crankshaft, shielding them from external contaminants and ensuring a sealed environment for optimal performance. The crankcase also plays a role in managing the lubrication system, which is essential for reducing friction and wear on the compressor’s internal components.

Accessory Drive Compatibility

When integrated with an accessory drive system, the Compressor Crankcase works in tandem with the drive mechanism to power the compressor. The accessory drive, typically a belt or chain, transfers rotational energy from the engine to the compressor. The crankcase must be designed to accommodate the mounting points and alignment requirements of the accessory drive, ensuring smooth and reliable operation.

EBM Compressor Applications

In systems utilizing an EBM (Externally Blown Motor) Compressor, the Compressor Crankcase is particularly important. The EBM Compressor relies on external air flow to cool the motor and enhance efficiency. The crankcase must be designed to allow for this airflow while still providing a secure enclosure for the compressor’s internal components. This dual functionality ensures that the compressor operates within optimal temperature ranges, prolonging its lifespan and maintaining performance.

Air Management Systems

In broader air management systems, the Compressor Crankcase contributes to the overall efficiency and reliability of the system. By housing the compressor’s critical components, it allows for better control over the compression process, leading to more consistent air delivery. This is especially important in applications where precise air pressure and flow are required, such as in industrial processes or automotive air suspension systems.

Summary of Component Interaction

- Air Compressor: The crankcase protects and houses the compressor’s internal components, ensuring efficient air compression.

- Accessory Drive: The crankcase must be compatible with the accessory drive to transfer energy efficiently from the engine to the compressor.

- EBM Compressor: The crankcase allows for external airflow to cool the motor, enhancing the compressor’s efficiency and reliability.

- Air Management Systems: The crankcase contributes to the overall efficiency and reliability of air delivery systems by housing and protecting the compressor’s critical components.

Conclusion

The Cummins 3063644 Compressor Crankcase is a critical component in heavy-duty truck engines, ensuring the efficient operation and longevity of the compressor system. Its robust construction, precise engineering, and seamless integration with other components make it a reliable and cost-effective solution for maintaining engine performance. Regular maintenance and proper installation are essential to maximize the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.