This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

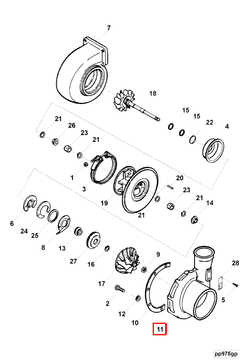

The HC3 Compressor Housing, identified by part number 3502388, is a component manufactured by Cummins, a leader in the commercial truck industry. This housing is integral to heavy-duty truck applications, particularly within the air braking system. Cummins is renowned for its commitment to quality, innovation, and customer satisfaction, making the HC3 Compressor Housing a reliable choice for maintaining efficient and safe braking operations in commercial vehicles 1.

Function and Operation

This Cummins part plays a role in the truck’s air braking system by facilitating the compression of air. It is designed to house the compressor mechanism, which is responsible for generating the compressed air required for the operation of the braking system. The housing contributes to maintaining system pressure, ensuring that the brakes can be applied effectively under various driving conditions. Its design allows for efficient air compression and helps in sustaining the necessary pressure levels within the system 2.

Key Features

The HC3 Compressor Housing is characterized by its robust design and construction. It is made from high-quality materials that offer structural integrity and durability. The housing is engineered to withstand the high pressures and temperatures associated with the compression process. Unique design elements may include reinforced sections to enhance performance and longevity, as well as features that facilitate easier maintenance and repair 3.

Benefits

This part offers several advantages. Its efficient design contributes to improved system performance, potentially leading to better fuel economy. The housing’s durability and reliability can result in longer service intervals, reducing the need for frequent replacements. Additionally, the high-quality construction ensures consistent performance, which is vital for the safety and efficiency of the air braking system.

Installation and Compatibility

Proper installation of the HC3 Compressor Housing is crucial for ensuring optimal performance and longevity. Installation procedures should follow manufacturer guidelines to avoid damage to the component or the system. Compatibility with various Cummins engine models and other truck makes and models should be verified to ensure seamless integration and operation within the intended system.

Maintenance and Troubleshooting

Routine maintenance of the HC3 Compressor Housing is important for its longevity and optimal performance. This may include regular inspections for signs of wear or damage, cleaning, and lubrication of moving parts as per manufacturer recommendations. Common issues that may arise include leaks or reduced efficiency, which can often be diagnosed through systematic checks and addressed through repairs or replacements as necessary.

Performance Enhancements

The HC3 Compressor Housing contributes to the overall performance of the air braking system by ensuring efficient air delivery rates and maintaining system pressure. Its design and construction play a role in enhancing braking efficiency, which is critical for the safe operation of heavy-duty trucks. The housing’s ability to withstand high pressures and temperatures ensures consistent performance under demanding conditions.

Safety Considerations

When working with the HC3 Compressor Housing, it is important to observe safety guidelines and precautions. This includes proper handling during installation and maintenance to prevent accidents or component failure. Following manufacturer instructions for installation, operation, and maintenance is crucial to ensure the safety and reliability of the air braking system.

Cummins Overview

Cummins Inc. has a long-standing reputation in the commercial truck industry for its quality products and innovative solutions. The company offers a wide range of products designed to meet the needs of various applications, with a strong emphasis on reliability, performance, and customer satisfaction. Cummins’ commitment to excellence is evident in its product development and support services, making it a preferred choice for commercial vehicle operators and manufacturers.

Integration of Part 3502388 HC3 Compressor Housing in Engine Systems

The HC3 Compressor Housing, identified by part number 3502388, is a specialized component designed to enhance the performance of turbocharger systems. Its role is integral in optimizing the airflow dynamics within the turbocharger, which in turn affects the overall efficiency and power output of the engine.

When integrating the HC3 Compressor Housing into a turbocharger system, it is essential to consider its interaction with other components. The housing is designed to fit snugly around the compressor wheel, ensuring a secure and airtight seal. This seal is vital for maintaining the pressure differentials necessary for efficient turbocharging.

In a turbocharger kit, the HC3 Compressor Housing works in conjunction with the turbocharger’s turbine housing. The housing directs the compressed air from the compressor wheel into the intake manifold, where it mixes with fuel before combustion. This process increases the engine’s power output without significantly increasing fuel consumption.

For systems utilizing a turbocharger without a housing (TRB), the HC3 Compressor Housing provides a structured pathway for the compressed air. This structured pathway is more efficient than an unhoused system, leading to better overall performance.

In performance parts applications, the HC3 Compressor Housing is often chosen for its ability to handle higher airflow volumes. This capability is particularly beneficial in high-performance engines where maximizing airflow is key to achieving desired power levels.

Overall, the HC3 Compressor Housing plays a significant role in enhancing the functionality and performance of turbocharger systems across various engine configurations.

Conclusion

The HC3 Compressor Housing (part number 3502388) is a critical component in the air braking and turbocharger systems of heavy-duty trucks and engines. Its robust design, efficient operation, and compatibility with various Cummins engine models make it a valuable asset for maintaining system performance and reliability. Proper installation, maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this part.

-

Hilgers, M., & Achenbach, W. (2021). Vocational Vehicles and Applications. Springer Vieweg.

↩ -

Lakshminarayanan, P. A., & Aghav, Y. V. (2010). Modelling Diesel Combustion. Springer Science.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.