This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

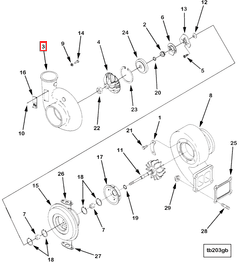

The 3503291 Compressor Housing by Cummins is a vital component in the turbocharger system of heavy-duty trucks. It plays a role in enhancing the performance and efficiency of the engine. This housing is designed to optimize the airflow within the turbocharger, contributing to improved power output and fuel efficiency.

Basic Concepts of Compressor Housing

Compressor housings are integral to the functionality of turbocharger systems. They encase the compressor wheel, which is responsible for compressing the intake air before it enters the engine. This compression increases the air density, allowing more oxygen to enter the combustion chamber. As a result, the engine can burn more fuel efficiently, leading to enhanced performance. The design and material of the compressor housing are crucial in ensuring that it can withstand the high pressures and temperatures generated during operation 1.

Purpose of the 3503291 Compressor Housing

This Cummins part is specifically engineered to improve the efficiency and power output of heavy-duty truck engines. By optimizing the airflow through the turbocharger, it ensures that the engine receives a consistent supply of compressed air. This results in more efficient combustion, leading to increased power and better fuel economy. The housing also plays a role in reducing turbo lag, which is the delay between the accelerator pedal being pressed and the turbocharger spooling up to provide boost 2.

Key Features

The 3503291 Compressor Housing boasts several key features that set it apart from other compressor housings. Its design is precision-engineered to ensure optimal airflow and efficiency. The housing is constructed from high-quality materials that can endure the extreme conditions within the turbocharger. Additionally, it features a robust construction that enhances durability and reliability. The unique attributes of this compressor housing contribute to its superior performance and longevity 3.

Benefits

The advantages of the 3503291 Compressor Housing are numerous. It provides improved engine performance by ensuring efficient airflow through the turbocharger. This leads to increased power output and better throttle response. Additionally, the housing contributes to enhanced fuel efficiency, reducing operating costs for fleet operators. Its durable construction ensures long-lasting performance, minimizing the need for frequent replacements 4.

Installation Process

Proper installation of the 3503291 Compressor Housing is crucial for ensuring optimal performance. The process involves several steps, including preparing the turbocharger for installation, aligning the housing with the compressor wheel, and securing it in place. It is important to follow the manufacturer’s guidelines to ensure that the housing is installed correctly. This includes checking for proper alignment, ensuring all fasteners are tightened to the specified torque, and verifying that there are no leaks in the system.

Common Issues and Troubleshooting

Typical problems associated with compressor housings include leaks, cracks, and improper installation. These issues can lead to reduced performance and efficiency. To address these problems, it is important to conduct regular inspections and maintenance. Troubleshooting steps may involve checking for leaks, inspecting the housing for cracks or damage, and ensuring that all fasteners are secure. In some cases, replacement of the housing may be necessary to restore optimal performance.

Maintenance Tips

To ensure the longevity and reliable performance of the 3503291 Compressor Housing, regular maintenance is essential. This includes inspecting the housing for signs of wear or damage, cleaning it to remove any debris or buildup, and ensuring that all fasteners are tight. Additionally, it is important to follow the manufacturer’s guidelines for maintenance intervals and replacement. Regular maintenance will help to prevent issues and ensure that the compressor housing continues to perform at its best.

Compatibility and Applications

The 3503291 Compressor Housing is compatible with a range of heavy-duty truck models and engine types. Its applications extend to various operating conditions, making it a versatile component for fleet operators. Ensuring compatibility with the specific truck model and engine type is crucial for optimal performance and efficiency.

Cummins Overview

Cummins Inc. is a renowned manufacturer in the automotive industry, particularly known for its heavy-duty truck components. With a rich history of innovation and quality, Cummins offers a wide range of products designed to enhance the performance and reliability of engines. The company’s reputation for excellence is built on its commitment to delivering high-quality, durable components that meet the demanding needs of the industry.

Cummins Compressor Housing Part 3503291 Compatibility

The Cummins Compressor Housing part number 3503291 is a critical component designed to fit seamlessly with several engine models. This part is engineered to ensure optimal performance and durability, making it a reliable choice for various applications.

L10 MECHANICAL Engines

The L10 MECHANICAL engine series is one of the primary beneficiaries of the 3503291 Compressor Housing. This part is specifically tailored to integrate with the L10 MECHANICAL engine, ensuring that it meets the rigorous demands of heavy-duty operations. The design and material of the housing are chosen to withstand the high pressures and temperatures typical in these engines, providing a robust solution for maintaining engine efficiency and longevity.

Other Compatible Engines

While the L10 MECHANICAL engines are a primary focus, the 3503291 Compressor Housing is also compatible with other Cummins engine models. This versatility makes it a valuable component for technicians and fleet operators who need a reliable part that can be used across multiple engine types. The compatibility extends to various configurations and specifications, ensuring that the housing fits snugly and functions as intended in different engine setups.

The precision engineering of the 3503291 Compressor Housing guarantees that it will fit perfectly with the specified engines, providing a seamless connection that enhances overall engine performance.

Role of Part 3503291 Compressor Housing in Engine Systems

The Compressor Housing, identified by part number 3503291, is an integral component in the assembly and operation of various turbocharger systems, including aftermarket turbochargers and high-performance setups like the H2 turbocharger.

In the context of an aftermarket turbocharger, the Compressor Housing encases the compressor wheel, which is responsible for compressing the intake air before it enters the engine’s combustion chambers. This housing ensures that the compressed air is directed efficiently, minimizing energy loss and maximizing the turbocharger’s performance.

For H2 turbochargers, which are known for their high-performance capabilities, the Compressor Housing plays a similar yet more demanding role. Given the increased air flow and pressure in H2 systems, the housing must be precisely engineered to withstand these conditions while maintaining optimal airflow dynamics.

When considering performance parts and turbocharger kits, the Compressor Housing is often a point of upgrade. Enhanced housings can improve the efficiency of the compressor wheel, leading to better overall engine performance. These upgrades are particularly noticeable in high-performance applications where every increment of efficiency can lead to significant gains in power output.

The location of the turbocharger within the engine system also influences the design and function of the Compressor Housing. Whether the turbocharger is mounted in a front-mounted intercooled (FMIC) configuration or in a traditional exhaust-mounted position, the housing must be designed to integrate seamlessly with the engine’s air intake and exhaust systems.

Conclusion

In summary, the Compressor Housing (part 3503291) is a key component in ensuring that the turbocharger operates efficiently, contributing to the overall performance and reliability of the engine system. Its role in optimizing airflow, enhancing engine efficiency, and providing durable construction makes it an essential part for heavy-duty truck engines.

-

R. Matthew Brach, SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety, SAE Books, 2023.

↩ -

Robert Fischer, Ferit Kucukay, Gunter Jurgens, Rolf Najork, and Burkhard Pollak, The Automotive Transmission Book Powertrain, Springer, 2015.

↩ -

Robert Bosch GmbH, Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition, Springer Vieweg, 2007.

↩ -

Saiful Bari, Diesel Engine Combustion, Emissions and Condition Monitoring, InTech, 2013.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.