This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

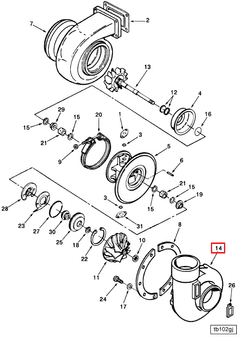

The Cummins 3521080 Compressor Housing is a component designed for use in heavy-duty truck engines. It plays a role in the turbocharger system, contributing to the overall performance and efficiency of the engine. Understanding its function and importance can provide valuable insights into maintaining and optimizing heavy-duty truck operations.

Basic Concepts of Compressor Housing

A compressor housing is a part of the turbocharger system. It encases the compressor wheel, which is responsible for compressing the air entering the engine. This compressed air mixes with fuel to create a more powerful combustion, thereby enhancing engine performance. The compressor housing ensures that the compressor wheel operates efficiently and is protected from external elements 1.

Purpose of the 3521080 Compressor Housing

The 3521080 Compressor Housing provides a secure and efficient environment for the compressor wheel. It contributes to engine efficiency by ensuring that the air compression process is optimized. This, in turn, allows the engine to perform at higher levels, providing better power output and fuel efficiency 2.

Key Features

The 3521080 Compressor Housing is characterized by several key features that enhance its performance and durability. It is designed with precision to ensure a perfect fit within the turbocharger system. The materials used in its construction are chosen for their strength and resistance to wear, ensuring longevity. Additionally, the housing may include specific design elements that improve airflow and reduce turbulence, further enhancing engine performance 3.

Benefits

Using the 3521080 Compressor Housing can lead to several benefits. These include improved engine performance due to optimized air compression, increased fuel efficiency as a result of more efficient combustion, and enhanced durability thanks to the robust construction of the housing. These factors contribute to the overall reliability and effectiveness of the engine 4.

Installation Process

Installing the 3521080 Compressor Housing involves several steps to ensure proper integration into the turbocharger system. It is important to follow manufacturer guidelines for prerequisites and tools required. Best practices include ensuring a clean and debris-free installation area, using the correct torque specifications for fastening, and verifying that all connections are secure and properly aligned 5.

Common Issues and Troubleshooting

Common issues with the 3521080 Compressor Housing may include leaks, cracks, or damage to the housing. Troubleshooting these problems involves inspecting the housing for signs of wear or damage, checking connections for tightness, and ensuring that the compressor wheel is functioning correctly. Solutions may range from simple repairs to replacement of the housing, depending on the severity of the issue 6.

Maintenance Tips

To ensure optimal performance and longevity of the 3521080 Compressor Housing, regular maintenance is recommended. This includes inspecting the housing for signs of wear or damage, cleaning it to remove any buildup that could affect performance, and following manufacturer guidelines for replacement intervals. Proper maintenance can help prevent issues and ensure the housing continues to contribute to efficient engine operation 7.

Cummins Overview

Cummins Inc. is a leader in the design, manufacture, and distribution of engines, filtration, and power generation products. With a history of innovation and commitment to quality, Cummins has established a strong reputation in the automotive industry. The company’s product offerings include a wide range of engines and components designed for various applications, demonstrating a dedication to meeting the needs of its customers with reliable and high-performance solutions 8.

Cummins Compressor Housing Part 3521080 Compatibility

The Cummins Compressor Housing part number 3521080 is designed to fit seamlessly with various engine models, ensuring optimal performance and reliability. This part is integral to the engine’s air intake system, facilitating the compression of air before it enters the combustion chamber.

N14 Mechanical Engines

The N14 Mechanical engine series, known for its robust design and durability, incorporates the 3521080 Compressor Housing. This part is engineered to withstand the high pressures and temperatures associated with these engines, ensuring efficient operation and longevity.

Group Compatibility

The 3521080 Compressor Housing is not limited to a single engine model but is compatible with a range of Cummins engines. Its design allows it to fit various configurations, making it a versatile component across different engine groups. This compatibility ensures that technicians and fleet managers can easily source and install the part, minimizing downtime and maintenance costs.

By integrating the 3521080 Compressor Housing into their maintenance routines, users can expect improved engine performance and reliability, contributing to the overall efficiency of their operations.

Role of Compressor Housing (Part 3521080) in Engine Systems

The Compressor Housing (Part 3521080) is an integral component in various engine systems, particularly those involving turbochargers. Its primary function is to house the compressor wheel, which plays a significant role in the pressurization of intake air.

In an Aftermarket Turbocharger setup, the Compressor Housing is designed to withstand higher pressures and temperatures compared to stock units. This allows for increased airflow, which is essential for performance enhancements. The housing must be precisely engineered to ensure a snug fit with the turbocharger’s components, facilitating efficient air compression and minimal leakage.

When dealing with a Campaign Kit, which often includes upgrades or replacements for turbocharger components, the Compressor Housing is a key element. It ensures that the new or upgraded compressor wheel is securely held in place, allowing for optimal performance and reliability. The housing’s design may also incorporate features to improve heat dissipation, which is vital for maintaining component integrity under high-stress conditions.

In the context of a Heat3b Turbocharger, the Compressor Housing is specifically tailored to handle the extreme thermal loads generated by this high-performance turbocharger. The material and design of the housing are critical for dissipating heat away from the compressor wheel, thereby preventing thermal degradation and ensuring consistent performance.

For Performance Parts that aim to maximize engine output, the Compressor Housing must be robust and efficient. It often features advanced materials and coatings to enhance durability and reduce friction. The housing’s design may also include aerodynamic improvements to optimize airflow and reduce turbulence, contributing to overall engine efficiency.

In a standard Turbocharger system, the Compressor Housing works in tandem with the turbine housing to create a balanced pressure system. The housing must be meticulously machined to ensure precise fitment with the compressor wheel and other turbocharger components, allowing for smooth operation and reliable performance.

Lastly, in a Turbocharger Kit, which typically includes a variety of components aimed at upgrading or replacing existing turbocharger parts, the Compressor Housing serves as the foundation for the compressor assembly. Its design and material must complement the other kit components to ensure seamless integration and enhanced performance.

Conclusion

The Cummins 3521080 Compressor Housing is a critical component in the turbocharger system of heavy-duty truck engines. Its role in optimizing air compression, enhancing engine performance, and ensuring durability makes it an essential part of engine maintenance and optimization. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

-

Automotive Braking Systems CDX Master Automotive Technician Series, Nicholas Goodnight and Kirk VanGelder, Jones Bartlett Learning, 2019

↩ -

Vehicle Crash Dynamics, Matthew Huang, CRC Press, 2002

↩ -

Diesel Engine Management Systems and Components, Konrad Reif, Springer, 2014

↩ -

Diesel Engine Management Systems and Components, Konrad Reif, Springer, 2014

↩ -

ISB5.9 CM2880 B149, Bulletin Number 5467238, Operation and Maintenance Manual

↩ -

Diesel Engine Management Systems and Components, Konrad Reif, Springer, 2014

↩ -

ISB5.9 CM2880 B149, Bulletin Number 5467238, Operation and Maintenance Manual

↩ -

Diesel Engine Management Systems and Components, Konrad Reif, Springer, 2014

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.