This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

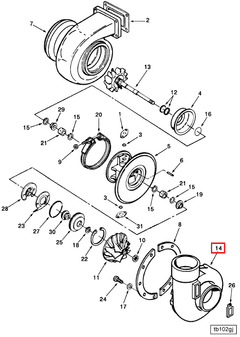

The Compressor Housing 3521081, a component manufactured by Cummins, is essential in the automotive and heavy-duty truck industry. This housing is crucial for the operation of heavy-duty trucks, enhancing engine system performance and efficiency.

Function and Operation

This Cummins part facilitates the compression of air for the turbocharger. It encases the compressor wheel and directs the flow of air, ensuring a steady and pressurized air supply to the turbocharger. This pressurized air, when mixed with fuel in the combustion chamber, leads to more efficient and powerful engine operation 1.

Key Features

The design and construction of the Compressor Housing 3521081 are characterized by high-quality materials and meticulous build standards. It is typically made from durable alloys that can withstand the high pressures and temperatures associated with turbocharger operation. The housing is engineered to provide a precise fit around the compressor wheel, minimizing air leaks and maximizing efficiency. Additionally, its construction includes features that enhance cooling and reduce thermal stress, contributing to its longevity and performance under demanding conditions 2.

Benefits

The Compressor Housing 3521081 offers several advantages. It contributes to improved engine efficiency by ensuring that the turbocharger receives a consistent and pressurized air supply. This leads to enhanced engine performance, allowing for better acceleration and power output. Furthermore, the robust construction of the housing ensures reliability, even in the most demanding operating environments, which is crucial for heavy-duty truck applications.

Installation and Compatibility

Proper installation of the Compressor Housing 3521081 is vital for ensuring optimal performance and longevity. It is important to follow manufacturer guidelines during installation to avoid common pitfalls such as improper sealing or misalignment. Preparations may include cleaning the installation area and inspecting the housing for any damage prior to installation. Ensuring that all connections are secure and that the housing is properly aligned with the turbocharger are key considerations.

Maintenance and Troubleshooting

Routine maintenance of the Compressor Housing 3521081 is important for prolonging its lifespan. This includes regular inspections for signs of wear or damage, ensuring that all connections remain tight, and cleaning the housing to remove any buildup that could impede airflow. Common issues may include leaks or reduced efficiency, which can often be traced back to wear on the housing or compressor wheel. Troubleshooting steps may involve inspecting these components for damage and replacing them if necessary.

Performance Enhancements

There are potential upgrades or modifications that can be made to the Compressor Housing 3521081 to further optimize engine performance and efficiency. These may include the use of higher-performance materials or designs that offer improved airflow or reduced weight. Additionally, ensuring that the housing is part of a well-matched turbocharger system can lead to significant gains in engine performance.

Cummins Overview

Cummins Inc. is a leader in the design, manufacture, and distribution of diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has built a reputation for innovation, quality, and reliability in the automotive components industry. The company’s commitment to advancing technology and meeting the needs of its customers is evident in its wide range of products, including the Compressor Housing 3521081 3.

Conclusion

The Compressor Housing 3521081 by Cummins is a vital component in enhancing the performance and efficiency of heavy-duty truck engines. Its robust design, precise engineering, and compatibility with various engine systems make it a reliable choice for demanding applications. Proper installation, maintenance, and potential upgrades can further optimize its performance, contributing to the overall efficiency and power output of the engine.

-

Reif, Konrad Ed. Brakes Brake Control and Driver Assistance Systems Function Regulation and Components. Springer, 2014.

↩ -

Mom, Gijs. The Evolution of Automotive Engineering: A Handbook. SAE International, 2023.

↩ -

Cummins Inc. Company Overview. Retrieved from Cummins Official Website.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.