This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

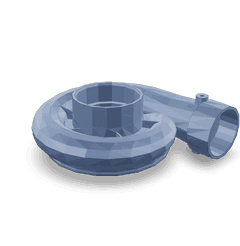

The Cummins 3523556 Compressor Housing is a vital component in the turbocharger system of commercial trucks. It enhances engine performance by facilitating efficient air compression, which is integral to the overall functionality and power output of the engine.

Basic Concepts of Compressor Housing

Compressor housings are fundamental to the operation of turbochargers. Their primary function is to house the compressor wheel, which compresses the intake air before it enters the engine. This process increases the air density, allowing more oxygen to enter the combustion chamber. As a result, the engine can burn more fuel per cycle, leading to improved efficiency and greater power output 1.

Purpose of the 3523556 Compressor Housing

The 3523556 Compressor Housing plays a specific role in the engine’s operation by ensuring that air is compressed efficiently. This component works in conjunction with the turbocharger to spin the compressor wheel at high speeds, thereby increasing the pressure of the intake air. The compressed air enhances combustion, contributing to the engine’s overall performance and power delivery 2.

Key Features

The 3523556 Compressor Housing is designed with several key features to ensure optimal performance. It is constructed from durable materials that can withstand the high pressures and temperatures within the turbocharger system. The housing is engineered for optimal airflow, ensuring that air moves smoothly through the compressor. Additionally, it is designed to integrate seamlessly with other turbocharger components, enhancing the system’s efficiency.

Benefits

The advantages of the 3523556 Compressor Housing include improved engine efficiency, increased power output, and enhanced durability. By ensuring efficient air compression, this component helps the engine operate more effectively, leading to better fuel economy and performance. Its robust construction allows it to endure the demanding conditions typical of commercial truck operations, providing reliable service over time 3.

Installation Process

Installing the 3523556 Compressor Housing requires careful attention to detail to ensure optimal performance and longevity. The process involves several steps: first, ensuring that the turbocharger is properly aligned and secured. Next, the compressor housing should be carefully fitted onto the turbocharger, ensuring that all connections are tight and secure. It is important to follow manufacturer guidelines to avoid common installation pitfalls.

Common Issues and Troubleshooting

Typical problems with the 3523556 Compressor Housing may include leaks or reduced efficiency. These issues can often be traced to improper installation, wear and tear, or damage to the housing. Troubleshooting steps may involve inspecting the housing for cracks or damage, ensuring all connections are secure, and checking for proper alignment within the turbocharger system. Addressing these issues promptly can help maintain optimal engine performance.

Maintenance Tips

To ensure the continued reliable performance of the 3523556 Compressor Housing, regular maintenance is crucial. This includes periodic inspections for signs of wear or damage, cleaning the housing to remove any buildup that could impede airflow, and following manufacturer-recommended service intervals. Additionally, knowing when to consider replacement can prevent more significant issues down the line.

Performance Enhancements

There are several potential upgrades or modifications that can be made to the 3523556 Compressor Housing to further enhance engine performance. These may include aftermarket options that offer improved airflow or durability. Additionally, tuning considerations can be explored to optimize the turbocharger system for specific engine requirements, leading to gains in power and efficiency.

Cummins Overview

Cummins Inc. is a renowned manufacturer in the commercial truck industry, known for its high-quality and reliable products. With a rich history and a diverse product range, Cummins has established a strong reputation for delivering performance and durability. This background underscores the quality and reliability of the 3523556 Compressor Housing, making it a trusted component in the turbocharger systems of commercial trucks.

Role of Part 3523556 Compressor Housing in Engine Systems

The integration of part 3523556 Compressor Housing within various engine systems significantly enhances performance and efficiency. When paired with an aftermarket turbocharger, this component ensures optimal airflow management, which is essential for maximizing the turbocharger’s potential. The Compressor Housing acts as a vital interface, directing compressed air into the engine’s intake system with precision.

In the context of a turbocharger kit, the Compressor Housing works in tandem with other components to maintain consistent pressure levels. This balance is key to preventing issues such as turbo lag and ensuring smooth power delivery. The kit often includes performance parts designed to withstand higher pressures and temperatures, making the Compressor Housing an integral part of this setup.

For systems utilizing a Turbo T18A KV12, the Compressor Housing plays a role in fine-tuning the airflow to match the specific requirements of this turbocharger model. This customization allows for better throttle response and improved overall engine performance.

When considering a Turbocharger T18-A Kit, the Compressor Housing is instrumental in achieving the desired boost levels. It helps in regulating the air-fuel mixture, which is critical for combustion efficiency. The housing’s design allows for adjustments that can be made to cater to different driving conditions, whether for everyday use or high-performance scenarios.

Conclusion

In summary, the 3523556 Compressor Housing is a fundamental component in various engine systems, contributing to enhanced airflow, pressure regulation, and overall engine performance. Its role in conjunction with turbochargers and related kits is indispensable for achieving optimal results in both stock and modified engine setups.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.