This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

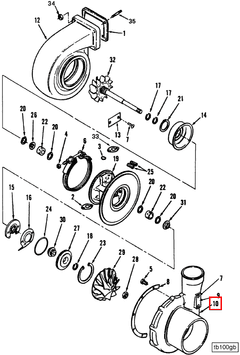

The Cummins 3523781 Compressor Housing is a component designed for use in turbocharger systems, specifically tailored for commercial truck engines. It plays a role in enhancing engine performance by facilitating efficient airflow and boost pressure within the engine. This housing is integral to the turbocharger’s operation, contributing to the overall efficiency and power output of the truck’s engine 1.

Basic Concepts of Compressor Housing

Compressor housings are fundamental to the operation of turbocharger systems. They encase the compressor wheel, which spins at high speeds to compress incoming air before it enters the engine’s combustion chambers. This compressed air increases the oxygen available for combustion, allowing the engine to burn more fuel efficiently and produce more power 4. The design and material of the compressor housing are critical for maintaining the integrity of the compressed air and ensuring efficient operation of the turbocharger.

Purpose of the 3523781 Compressor Housing

This part is specifically engineered to enhance the operation of a truck’s engine by improving airflow and boost pressure. It houses the compressor wheel, which plays a role in compressing the air entering the engine. This increased airflow contributes to higher engine efficiency and performance, allowing the engine to operate more effectively under various conditions. The housing’s design also helps in managing the temperature and pressure of the compressed air, which is vital for maintaining engine performance and durability 3.

Key Features

This Cummins part is characterized by its durable construction and precise engineering. It is designed to withstand the high pressures and temperatures associated with turbocharger operation. The housing is compatible with Cummins turbochargers, ensuring seamless integration with the engine system. Its construction may include materials and design elements that enhance its durability and efficiency, such as heat-resistant alloys and aerodynamic shaping to optimize airflow 2.

Benefits

Utilizing the 3523781 Compressor Housing can lead to enhanced engine performance, increased fuel efficiency, and improved reliability. The efficient compression of air facilitated by the housing allows the engine to operate more efficiently, potentially leading to better fuel economy. Additionally, the durable construction of the housing contributes to the overall reliability of the turbocharger system, reducing the likelihood of failures and extending the maintenance intervals 1.

Installation and Compatibility

Proper installation of this part involves following manufacturer guidelines to ensure it is correctly fitted and sealed. This may include preparations such as cleaning the installation area, using the correct tools, and following specific procedures to avoid damage to the housing or the turbocharger. Compatibility with various Cummins turbocharger models and engine configurations should be verified to ensure optimal performance and integration with the engine system 3.

Maintenance and Troubleshooting

Routine maintenance and inspection of the 3523781 Compressor Housing are important for ensuring optimal performance and longevity. This may involve checking for signs of wear, leaks, or cracks, and performing cleaning or repairs as necessary. Troubleshooting common issues such as performance degradation may involve inspecting the housing for damage, ensuring proper sealing, and verifying that it is correctly installed and integrated with the turbocharger system 4.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines and related technologies, with a strong reputation in the automotive industry for innovation and quality. The company has a history of developing reliable and efficient engine components, including turbochargers and compressor housings. Cummins’ commitment to quality and performance is evident in its product line, which is designed to meet the demanding requirements of commercial and industrial applications 2.

Compatibility with Cummins Engines

- NH/NT 855 Series: This part is specifically designed to integrate with the NH/NT 855 engines, ensuring a precise fit and reliable operation. This compatibility is crucial for maintaining the engine’s efficiency and longevity.

The design of the compressor housing is tailored to meet the specific requirements of these engines, ensuring that it can withstand the operational stresses and deliver consistent performance. This part is essential for the proper functioning of the engine’s air intake system, contributing to the overall reliability and efficiency of the engine 3.

Role of Part 3523781 Compressor Housing in Engine Systems

This part is an essential component that interfaces with various engine systems to enhance performance and efficiency. When integrated with an aftermarket turbocharger, this housing ensures optimal airflow management, which is vital for maximizing the turbocharger’s potential.

In conjunction with a turbocharger kit, the compressor housing plays a significant role in maintaining the balance between air intake and exhaust gas expulsion. This balance is necessary for the turbocharger to operate efficiently across a wide range of engine speeds.

When addressing issues such as turbo surge, the compressor housing’s design helps in stabilizing airflow, reducing the likelihood of surge events that can lead to inefficient combustion and potential damage to the engine.

Overall, this part works seamlessly with these components to ensure that the engine system operates at peak performance, providing reliable power delivery and improved fuel efficiency 4.

Conclusion

The 3523781 Compressor Housing is a critical component in the operation of Cummins turbochargers, designed to enhance engine performance, efficiency, and reliability. Its durable construction, precise engineering, and compatibility with various Cummins engines make it an essential part for maintaining optimal engine operation. Proper installation, maintenance, and troubleshooting are key to ensuring the longevity and performance of this part, contributing to the overall efficiency and power output of commercial truck engines.

-

Hilgers, Michael. Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature, 2023.

↩ ↩ -

Hu, Haoran, Rudy Smaling, and Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩ ↩ -

Hilgers, Michael. Electrical Systems and Mechatronics, Second Edition. Springer Vieweg, 2023.

↩ ↩ ↩ -

Sobey, Ed. A Field Guide to Automotive Technology. Chicago Review Press, 2009.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.