This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3524077 Compressor Housing is a component designed for heavy-duty truck applications. It plays a role in the engine system by facilitating efficient air compression, which is vital for the combustion process. Understanding its function and significance can provide insights into how it contributes to the overall performance and reliability of heavy-duty trucks 1.

Basic Concepts of Compressor Housing

A compressor housing is a part of the turbocharger system that encloses the compressor wheel. Its function is to direct and manage the flow of air into the engine, enhancing the compression process. This increased air pressure allows for more fuel to be burned, resulting in greater power output. Compressor housings are typically manufactured from materials such as aluminum or cast iron, chosen for their durability, heat resistance, and ability to withstand high pressures 2.

Purpose of the 3524077 Compressor Housing

The 3524077 Compressor Housing is specifically designed to optimize the air compression process in heavy-duty truck engines. It interfaces with the turbocharger to ensure that air is efficiently compressed before entering the engine’s combustion chambers. This enhancement in air compression contributes to improved engine performance and fuel efficiency.

Key Features

The 3524077 Compressor Housing features a design that maximizes airflow and minimizes turbulence, which can lead to more efficient compression. It is constructed from high-quality materials that offer durability and resistance to the high temperatures and pressures encountered in heavy-duty applications. Unique attributes of this compressor housing include its precision engineering and compatibility with specific turbocharger models, ensuring optimal performance 3.

Benefits

Using the 3524077 Compressor Housing in heavy-duty truck applications can lead to several advantages. These include improved engine performance due to more efficient air compression, increased durability under demanding conditions, and enhanced fuel efficiency. Additionally, the design and materials used in this compressor housing contribute to its longevity, potentially offering cost benefits over time.

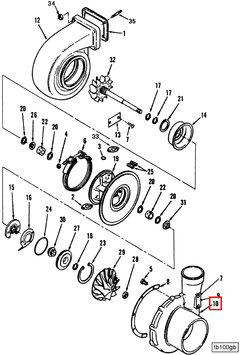

Installation Process

Installing the 3524077 Compressor Housing requires careful attention to detail. Prerequisites include ensuring the turbocharger and engine are clean and free of debris. Tools required may include wrenches, gasket scrapers, and torque wrenches. Best practices for installation involve following the manufacturer’s guidelines, ensuring all connections are secure, and verifying that the housing is properly aligned with the turbocharger.

Common Issues and Troubleshooting

Common problems associated with compressor housings can include leaks, cracks, or inefficient air compression. These issues may manifest as reduced engine performance or unusual noises from the turbocharger area. Troubleshooting tips include inspecting the housing for signs of damage, ensuring all connections are tight, and checking for proper alignment with the turbocharger.

Maintenance Tips

To prolong the lifespan of the 3524077 Compressor Housing, routine maintenance practices are recommended. These include regular inspection for signs of wear or damage, cleaning the housing to remove any buildup that could affect performance, and following the manufacturer’s guidelines for maintenance intervals. Identifying wear and tear early can prevent more significant issues down the line.

Cummins Overview

Cummins Inc. is a leader in the design, manufacture, and distribution of engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established a reputation for reliability and performance in the automotive and heavy-duty truck industry. Their products, including the 3524077 Compressor Housing, are designed with a focus on enhancing engine efficiency and durability.

Cummins Compressor Housing Part 3524077 Compatibility

The Cummins part number 3524077, identified as a Compressor Housing, is integral to the engine’s air intake system. This part is specifically designed to fit seamlessly within the architecture of various Cummins engines, ensuring optimal performance and reliability.

N14 CELECT Engine

The N14 CELECT engine, known for its robust design and efficiency, incorporates the Compressor Housing part 3524077. This component is crucial for the engine’s air management system, facilitating the compression of incoming air before it enters the combustion chamber. The fitment of this part in the N14 CELECT engine ensures that the engine can maintain its high performance standards, providing the necessary air pressure for efficient combustion.

Compatibility Considerations

When considering the use of the Compressor Housing part 3524077, it is essential to ensure that the part is compatible with the specific engine model. This compatibility is critical for maintaining the engine’s performance and longevity. The part’s design and specifications are tailored to meet the unique requirements of the engines it is intended for, ensuring a precise and reliable fit.

Installation and Maintenance

Proper installation of the Compressor Housing part 3524077 is crucial for the engine’s overall performance. Technicians should follow the manufacturer’s guidelines for installation to ensure that the part is correctly aligned and secured. Regular maintenance checks should be performed to inspect for any signs of wear or damage, ensuring that the air intake system functions efficiently.

Understanding the Role of Part 3524077 Compressor Housing in Engine Systems

The compressor housing, identified by part number 3524077, is an integral component within the turbocharger system of an engine. Its primary function is to encase and support the compressor wheel, which is responsible for compressing the intake air before it enters the engine’s combustion chambers. This compression increases the air density, allowing more oxygen to be mixed with the fuel, thereby enhancing combustion efficiency and power output.

Integration with EBM-Injector and EBM-Performance Parts

When paired with EBM-injectors and EBM-performance parts, the compressor housing plays a significant role in optimizing the fuel-air mixture. The EBM-injectors are precision-engineered to deliver fuel into the combustion chamber with high accuracy. The increased air pressure provided by the compressor housing ensures that the fuel is atomized more effectively, leading to a more complete burn and improved engine performance. EBM-performance parts, designed to work in harmony with the turbocharger system, further enhance the engine’s responsiveness and power delivery.

Synergy with EBM-Turbocharger and Heat3B Turbocharger

The compressor housing is a key component of both the EBM-turbocharger and the Heat3B turbocharger systems. In these setups, the housing not only protects the compressor wheel but also contributes to the overall efficiency of the turbocharger. The design of the housing affects the airflow dynamics, influencing how air flows into and out of the compressor. This, in turn, impacts the turbocharger’s ability to spool up quickly and maintain boost pressure across a wide range of engine speeds.

Interaction with Injector and Turbocharger Kit

In conjunction with standard injectors and a turbocharger kit, the compressor housing ensures that the engine receives a consistent supply of compressed air. This is particularly important in high-performance applications where precise air-fuel ratios are essential for maximizing power and efficiency. The turbocharger kit, which includes the compressor housing, turbocharger, and associated piping, works as a cohesive unit to deliver significant improvements in engine performance.

Role in Performance and Parts Ecosystem

Within the broader ecosystem of performance parts, the compressor housing is a fundamental piece. It interacts with various components to ensure that the engine operates at peak efficiency. Whether it’s part of a stock replacement or a high-performance upgrade, the compressor housing’s role in maintaining the integrity and performance of the turbocharger system cannot be overstated.

Conclusion

In summary, the compressor housing (part 3524077) is a vital component that enhances the functionality of the turbocharger system, working in tandem with injectors, performance parts, and turbocharger kits to deliver optimal engine performance.

-

Mom, Gijs. The Evolution of Automotive Engineering: A Handbook. SAE International, 2023.

↩ -

Robert Bosch GmbH. Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg, 2007.

↩ -

Hilgers, Michael. Chassis and Axles. Springer Vieweg, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.