This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

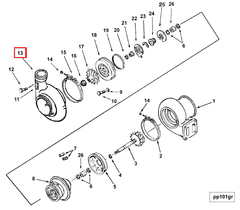

The Cummins 3524987 Compressor Housing is a vital component in the operation of heavy-duty trucks. It is integral to the turbocharger system, which enhances engine performance by increasing the efficiency of air intake. Understanding its role and significance within the broader context of truck components is fundamental for maintaining and optimizing heavy-duty truck operations.

Basic Concepts of Compressor Housing

A compressor housing is a part of the turbocharger system that encases the compressor wheel. Its function is to direct and manage the flow of air into the engine, compressing it to increase the oxygen available for combustion. This process, known as turbocharging, significantly boosts engine power and efficiency. The compressor housing plays a role in this process by ensuring that the compressed air is delivered smoothly and efficiently to the engine 1.

Purpose of the 3524987 Compressor Housing

This Cummins part is designed to enhance the performance of Cummins engines by improving the efficiency of the turbocharger system. It plays a role in maintaining the structural integrity of the compressor wheel while optimizing the airflow into the engine. This results in better engine efficiency and overall performance, contributing to the truck’s ability to handle heavy loads and operate under demanding conditions.

Key Features

This part is characterized by its robust material composition, typically made from high-strength alloys to withstand the high pressures and temperatures of the turbocharger system. Its design includes precise engineering to ensure optimal airflow and efficiency. Unique characteristics may include advanced sealing technologies to prevent leaks and enhance performance.

Benefits

Utilizing the 3524987 Compressor Housing offers several advantages, including improved engine performance due to more efficient air compression, increased durability thanks to its robust construction, and enhanced reliability under various operating conditions. These benefits contribute to better truck operation and maintenance efficiency, reducing downtime and operational costs 2.

Installation Process

Installing this part requires careful attention to ensure a proper and secure fit. The process involves removing the old housing, inspecting the turbocharger for any damage, and then fitting the new housing. Specific tools may be required to ensure a tight seal and proper alignment. Tips for a successful installation include checking for proper gasket placement and ensuring all bolts are tightened to the manufacturer’s specifications.

Common Issues and Troubleshooting

Common issues with compressor housings include leaks, cracks, and a decline in performance over time. Troubleshooting these issues involves inspecting the housing for visible damage, checking for proper seal integrity, and ensuring there are no obstructions in the airflow path. Solutions may range from repairing minor damage to replacing the housing if it is compromised.

Maintenance Tips

Regular maintenance of the 3524987 Compressor Housing is key to ensuring optimal performance and longevity. This includes periodic inspections for signs of wear or damage, cleaning the housing to remove any debris that could obstruct airflow, and following manufacturer recommendations for replacement intervals. Adhering to these maintenance practices helps maintain engine efficiency and reliability.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a rich history of innovation and quality, Cummins has established a strong reputation in the automotive and heavy-duty truck industry. The company’s commitment to customer satisfaction is evident in its focus on developing reliable and efficient components, like the 3524987 Compressor Housing, that contribute to the performance and durability of heavy-duty trucks.

Compatibility of Compressor Housing Part 3524987 with Cummins Engines

The Compressor Housing part 3524987, manufactured by Cummins, is a critical component that fits seamlessly into several Cummins engine models. This part is integral to the engine’s air intake system, ensuring efficient and reliable operation. Below is a detailed overview of its compatibility with specific Cummins engines.

N14 Mechanical Engines

The N14 Mechanical engine is a robust and dependable power unit widely used in various heavy-duty applications. The Compressor Housing part 3524987 is specifically designed to fit this engine model, providing a precise and secure fit that enhances the engine’s performance. Its design ensures optimal air flow and pressure, contributing to the engine’s overall efficiency and longevity.

NH/NT 855 Engines

The NH/NT 855 engines are another series where the Compressor Housing part 3524987 proves to be an essential component. These engines are known for their durability and high performance in demanding environments. The part’s compatibility with the NH/NT 855 engines ensures that the air intake system functions smoothly, maintaining the engine’s efficiency and reliability. The precise engineering of this compressor housing guarantees a perfect fit, facilitating seamless integration with the engine’s architecture.

By ensuring that the Compressor Housing part 3524987 is compatible with both the N14 Mechanical and NH/NT 855 engines, Cummins maintains a high standard of quality and performance across its engine lineup. This compatibility underscores Cummins’ commitment to providing reliable and efficient engine components that meet the rigorous demands of various applications.

Role of Part 3524987 Compressor Housing in Engine Systems

The compressor housing, identified by part number 3524987, is an integral component in the operation of various engine systems, particularly those utilizing turbochargers for enhanced performance. This housing encases the compressor wheel, which is driven by the turbine wheel via a shared shaft. As air enters the housing, it is compressed by the spinning compressor wheel before being forced into the engine’s intake manifold. This process increases the mass of air entering the combustion chamber, allowing for more fuel to be burned and thus boosting engine power output.

In the context of the 49 State 444 Turbocharger, the compressor housing works in tandem with the turbine housing to create a balanced turbo system. The efficiency of the compressor housing directly influences the turbocharger’s ability to deliver consistent boost pressure across a wide range of engine speeds. This is particularly important in performance applications where maintaining optimal boost levels is key to maximizing engine output.

When considering performance parts and turbocharger kits, the compressor housing’s design and material play significant roles in the overall efficiency and durability of the turbo system. High-quality materials and precision engineering ensure that the housing can withstand the high pressures and temperatures associated with forced induction, contributing to the longevity and reliability of the turbocharger.

For the BHT4C turbocharger, the compressor housing is designed to match the specific airflow requirements and pressure ratios of this turbo model. Its integration into the engine system is vital for achieving the desired performance gains, whether for street performance or competitive racing applications. The housing must be compatible with the turbo’s compressor wheel size and the engine’s airflow demands to ensure efficient operation and prevent issues such as compressor surge or overheating.

In summary, the compressor housing (part 3524987) is a key component in the functionality of turbochargers within engine systems. Its role in compressing intake air and contributing to the overall efficiency and performance of the turbo system cannot be overstated. Proper selection and integration of this part are essential for achieving the desired engine performance and reliability in both stock and modified applications.

Conclusion

The 3524987 Compressor Housing is a critical component in the turbocharger system of Cummins engines, enhancing engine performance and efficiency. Its robust design, compatibility with various Cummins engine models, and the role it plays in the turbocharging process underscore its importance in heavy-duty truck operations. Regular maintenance and proper installation are essential to ensure optimal performance and longevity of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.