This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3525220 Compressor Housing is a vital component in the turbocharger system of commercial trucks. It enhances engine performance by optimizing the air intake process, which is essential for maintaining efficient combustion and power output. This part is designed to work seamlessly with Cummins engines, ensuring that the turbocharger operates at peak efficiency.

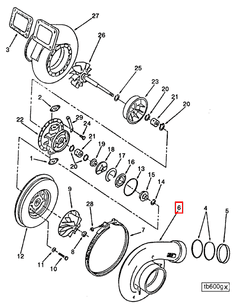

Basic Concepts of Compressor Housing

A compressor housing is a fundamental part of the turbocharger, encapsulating the compressor wheel and directing the flow of air into the engine. Its function is to increase the pressure of the air entering the engine, which in turn enhances the combustion process and improves overall engine efficiency 1. The principles of turbocharging involve compressing the intake air to increase its density, allowing more oxygen to enter the combustion chamber and thus boosting power output. The compressor housing plays a significant role in this process by ensuring that the compressed air is delivered efficiently to the engine.

Purpose of the 3525220 Compressor Housing

The 3525220 Compressor Housing specifically serves to increase the air intake in a truck’s engine, thereby boosting engine power. By housing the compressor wheel and managing the airflow, it ensures that the turbocharger operates effectively. This results in improved engine performance, allowing the truck to achieve higher power outputs and better fuel efficiency 2.

Key Features

The 3525220 Compressor Housing is characterized by its robust design and high-quality materials, which contribute to its performance and durability. It is engineered to withstand the high pressures and temperatures associated with turbocharging. The housing is typically made from durable materials such as aluminum or composite alloys, which offer a balance of strength and lightweight properties. Additionally, it features precise machining and tight tolerances to ensure optimal airflow and minimal leakage 3.

Benefits

Using the 3525220 Compressor Housing offers several benefits, including improved engine efficiency, increased power output, and enhanced reliability. These advantages translate to better performance and fuel economy for commercial trucks. The housing’s design ensures that the turbocharger operates efficiently, leading to smoother engine operation and reduced wear on other components. Furthermore, its durability contributes to the overall reliability of the engine system.

Installation Process

Installing the 3525220 Compressor Housing involves several steps to ensure proper fitting and functionality. Begin by ensuring that the engine is cool and the turbocharger is disconnected from the exhaust and intake systems. Use the appropriate tools to remove the old compressor housing and inspect the turbocharger for any damage. Clean the mating surfaces thoroughly to ensure a proper seal. Align the new housing with the turbocharger and secure it in place using the recommended torque specifications. Reconnect the intake and exhaust systems, and perform a leak check to confirm that the installation is secure and functioning correctly.

Common Issues and Troubleshooting

Common issues with the 3525220 Compressor Housing may include leaks, cracks, or a decline in performance. These problems can often be traced to improper installation, wear and tear, or damage from extreme operating conditions. To troubleshoot these issues, inspect the housing for any visible signs of damage or wear. Check the gaskets and seals for proper installation and condition. If leaks are detected, ensure that all connections are tight and that there are no gaps in the housing. In cases of performance decline, it may be necessary to inspect the turbocharger wheel and other components for damage or imbalance.

Maintenance Tips

Regular maintenance is key to ensuring the longevity and optimal performance of the 3525220 Compressor Housing. Inspect the housing at regular intervals for signs of wear or damage. Clean the housing and associated components to remove any buildup of dirt or debris that could affect performance. Follow the manufacturer’s guidelines for replacement intervals to ensure that the housing remains in good condition. Additionally, maintain the overall health of the turbocharger system by regularly checking the intake and exhaust systems for leaks or obstructions.

Cummins Overview

Cummins Inc. is a renowned manufacturer in the automotive industry, known for its commitment to innovation, quality, and customer satisfaction. Founded in 1919, Cummins has a long history of producing reliable and high-performance engine components. The company’s dedication to advancing technology and improving engine efficiency has established it as a leader in the field of diesel engines and turbochargers. Cummins’ products are designed to meet the demanding requirements of commercial applications, ensuring that customers receive durable and efficient components for their vehicles.

Role of Part 3525220 Compressor Housing in Engine Systems

The 3525220 Compressor Housing is an integral component in the operation of aftermarket turbochargers and performance parts. When integrated into a turbocharger system, this housing encases the compressor wheel, which is responsible for compressing the intake air before it enters the engine’s combustion chambers.

In a turbocharger kit, the compressor housing works in tandem with the turbine housing. As the turbine side of the turbocharger spins, driven by the engine’s exhaust gases, it imparts rotational energy to the compressor side. The compressor housing directs this energy to the compressor wheel, which increases the pressure of the intake air. This pressurized air allows for more fuel to be burned in the combustion process, thereby enhancing engine performance.

The efficiency of the compressor housing directly influences the overall performance of the turbocharger. A well-designed housing minimizes air turbulence and maximizes airflow, which is essential for optimal turbocharger function. In performance applications, the compressor housing may be upgraded to handle higher airflow demands, ensuring that the turbocharger can meet the increased air requirements of a modified engine.

Conclusion

The 3525220 Compressor Housing plays a significant role in the efficient operation of turbochargers and turbocharger kits. Its design and functionality are key to achieving the desired performance enhancements in aftermarket and performance-oriented engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.