This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3526129 Compressor Housing is a component designed to enhance the performance of turbocharger systems in commercial trucks. Its role is integral to the efficient operation of the turbocharger, which in turn plays a significant part in improving engine performance. By optimizing the airflow into the engine, the compressor housing contributes to better combustion efficiency and increased power output, making it a valuable component in the realm of heavy-duty trucking.

Basic Concepts of Compressor Housing

Compressor housings are fundamental to the operation of turbocharger systems. They encase the compressor wheel, which spins at high speeds to compress the intake air before it enters the engine. This compression increases the density of the air, allowing more oxygen to enter the combustion chamber. As a result, the engine can burn fuel more efficiently, leading to enhanced performance and fuel economy. The design and material of the compressor housing are critical to ensuring that this process is as effective as possible 1.

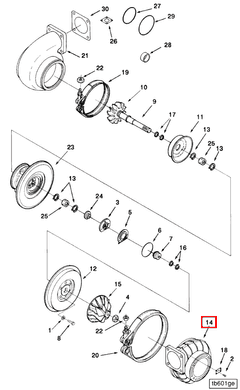

Purpose and Function of the 3526129 Compressor Housing

The 3526129 Compressor Housing is specifically engineered to work within Cummins turbocharger systems. It plays a role in the turbocharger system by housing the compressor wheel and directing the flow of compressed air into the engine. This component aids in compressing intake air, which improves combustion efficiency and contributes to a more powerful engine output. The precise engineering of this housing ensures that air is compressed efficiently and delivered smoothly to the engine 2.

Key Features

The Cummins 3526129 Compressor Housing is notable for its durable construction materials, which are designed to withstand the high pressures and temperatures within a turbocharger system. Its engineering precision ensures a tight fit and efficient operation within the turbocharger. Additionally, it is compatible with a range of Cummins turbochargers, making it a versatile component for various engine configurations 3.

Benefits of Using the 3526129 Compressor Housing

Installing the 3526129 Compressor Housing can lead to several advantages. These include improved engine performance due to more efficient air compression, increased fuel efficiency as a result of better combustion, and enhanced durability under the demanding conditions typical of commercial trucking operations. The robust construction of this component ensures it can withstand the rigors of heavy-duty use, contributing to the overall reliability of the engine 4.

Installation Considerations

When installing the 3526129 Compressor Housing, it is important to ensure compatibility with the specific Cummins turbocharger model in use. Preparatory steps may include inspecting the turbocharger for any damage or wear that could affect the installation. Following manufacturer guidelines for installation will help ensure that the compressor housing is fitted correctly, contributing to the efficient operation of the turbocharger system 5.

Maintenance and Troubleshooting

To maintain the 3526129 Compressor Housing and ensure optimal performance, regular inspections for signs of wear or damage are recommended. Common maintenance practices include cleaning the housing to remove any buildup that could affect airflow and checking for leaks or reduced efficiency. Troubleshooting techniques may involve inspecting the compressor wheel for damage and ensuring that all connections are secure and free from leaks 6.

Cummins Overview

Cummins Inc. is a well-established manufacturer within the commercial trucking industry, known for its wide range of diesel engines and related technologies. The company has a history of innovation and quality, with a product lineup that includes engines, filtration systems, and turbochargers. The 3526129 Compressor Housing is part of Cummins’ commitment to providing reliable and high-performance components for the commercial trucking sector 7.

Role of Part 3526129 Compressor Housing in Engine Systems

The Compressor Housing (Part 3526129) is an integral component in the operation of various engine systems, particularly those involving turbochargers. This housing encases the compressor wheel, which is driven by the turbine wheel via a shared shaft. The primary function of the compressor housing is to direct and accelerate the intake air, increasing its pressure and density before it enters the engine’s combustion chambers 8.

In a turbocharger system, the compressor housing works in tandem with the turbine housing. As exhaust gases spin the turbine wheel, the connected compressor wheel within the housing compresses the intake air. This pressurized air enhances the engine’s performance by allowing more oxygen to enter the combustion chamber, resulting in more efficient fuel burning and increased power output 9.

The interaction between the compressor housing and other engine components such as the intercooler, intake manifold, and fuel injection system is essential for optimizing engine performance. The pressurized air from the compressor housing must be effectively cooled by the intercooler to maintain its density, ensuring that the engine receives the maximum possible amount of oxygen. The intake manifold then distributes this compressed air to the cylinders, where it mixes with fuel and ignites, driving the pistons and generating power 10.

Conclusion

In summary, the compressor housing (Part 3526129) is a key element in the efficient operation of turbocharged engine systems. Its role in compressing intake air directly influences engine performance, making it a vital component in both standard and high-performance engine configurations.

-

Sheng, G. (2012). Vehicle Noise, Vibration and Sound Quality. SAE International.

↩ -

Boyce, M. P. (2011). Gas Turbine Engineering Handbook 4th Edition. Butterworth-Heinemann.

↩ -

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5659655.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5659655.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5659655.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5659655.

↩ -

Sheng, G. (2012). Vehicle Noise, Vibration and Sound Quality. SAE International.

↩ -

Boyce, M. P. (2011). Gas Turbine Engineering Handbook 4th Edition. Butterworth-Heinemann.

↩ -

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.