This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3528999 Compressor Housing is a vital component within the turbocharger system of commercial trucks. It plays a significant role in enhancing engine performance by optimizing the airflow dynamics and pressure ratios within the turbocharger. This component is designed to work seamlessly with Cummins engines, contributing to improved efficiency and power output in demanding applications 1.

Function and Operation

The compressor housing operates by directing and compressing the intake air before it enters the engine. This process increases the air density, allowing more oxygen to be available for combustion. The housing is engineered to manage airflow efficiently, maintaining optimal pressure ratios that enhance engine efficiency. Its design ensures that the compressed air is delivered smoothly to the engine, supporting consistent performance under various operating conditions 2.

Design and Construction

This part is constructed using high-quality materials that offer durability and heat resistance. The precision engineering involved in its design ensures that it can withstand the high temperatures and pressures present in the turbocharger system. The materials used are selected for their ability to maintain structural integrity and performance over extended periods, even in the harsh environments typical of commercial truck operations 3.

Key Features

Several key features distinguish the 3528999 Compressor Housing. Its aerodynamic design minimizes turbulence and maximizes airflow efficiency. The housing is meticulously integrated with the turbocharger, ensuring a seamless fit and optimal performance. Additionally, it is specifically designed to be compatible with Cummins engines, guaranteeing reliable operation and enhanced engine performance.

Benefits of Using Cummins 3528999 Compressor Housing

Utilizing the 3528999 Compressor Housing offers several advantages. It contributes to improved engine performance by ensuring efficient airflow and pressure management. This results in increased fuel efficiency, as the engine operates more effectively with the optimized air supply. Furthermore, the robust design and high-quality materials used in its construction enhance the reliability and longevity of the component, making it a valuable asset in demanding commercial truck applications.

Installation Process

Proper installation of the 3528999 Compressor Housing is crucial for ensuring optimal performance. The process involves several steps, including careful alignment with the turbocharger and adherence to specified torque values. Best practices dictate that the housing should be installed in a clean environment to prevent contamination, and all connections should be securely fastened to avoid leaks or misalignments that could affect performance.

Maintenance and Troubleshooting

Regular maintenance of the 3528999 Compressor Housing is essential to prolong its lifespan and ensure consistent performance. This includes periodic inspections for signs of wear or damage, cleaning to remove any debris that may accumulate, and checking for proper alignment and secure fittings. Common issues may include leaks or reduced efficiency, which can often be diagnosed through visual inspection and performance testing. Adhering to recommended maintenance schedules will help maintain the component’s effectiveness.

Performance Enhancements

The 3528999 Compressor Housing plays a role in enhancing overall engine performance. By optimizing airflow and pressure, it contributes to increased power output and torque delivery. This results in improved acceleration and overall engine responsiveness. Additionally, the efficient airflow management leads to better fuel economy, making it a valuable component for commercial truck applications where performance and efficiency are paramount.

Compatibility and Applications

The 3528999 Compressor Housing is designed for use with specific Cummins engine models and is commonly found in various commercial truck applications. Its versatility allows it to be utilized across different truck configurations, providing reliable performance in a range of operating conditions. This compatibility ensures that it can be effectively integrated into diverse commercial truck fleets.

Cummins Corporation

Cummins Inc. is a renowned manufacturer in the automotive and heavy-duty truck industry, with a long-standing reputation for innovation and quality. The company is committed to producing high-performance components that meet the demanding requirements of commercial applications. Cummins’ dedication to excellence is evident in the design and construction of components like the 3528999 Compressor Housing, which embodies the company’s focus on reliability, efficiency, and durability.

Compatibility

The 3528999 Compressor Housing is compatible with several Cummins engine models, including the M11 CELECT PLUS and M11 MECHANICAL. This part is engineered to ensure optimal performance and reliability in various engine configurations.

M11 CELECT PLUS

The M11 CELECT PLUS engine benefits from the precision engineering of the 3528999 Compressor Housing. This part is designed to integrate smoothly with the engine’s electronic control system, enhancing the overall efficiency and responsiveness of the engine. The housing is crafted to withstand the high pressures and temperatures associated with the M11 CELECT PLUS, ensuring durability and longevity.

M11 MECHANICAL

Similarly, the M11 MECHANICAL engine is compatible with the 3528999 Compressor Housing. This part is tailored to fit the mechanical control system of the M11 MECHANICAL, providing a robust and reliable housing solution. The design of the housing ensures that it can handle the mechanical stresses and operational demands of the engine, contributing to its overall performance and efficiency.

Role in Engine Systems

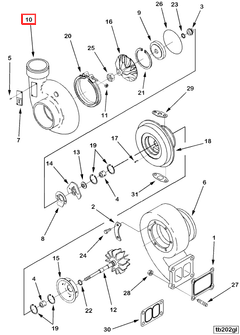

The 3528999 Compressor Housing is an integral component in the assembly and operation of turbocharger systems. It is specifically designed to encase and support the compressor wheel, which is a key element in the turbocharger’s function of compressing intake air before it enters the engine’s combustion chambers.

Integration with Turbocharger

When integrating the 3528999 Compressor Housing with a turbocharger, it ensures a secure fit around the compressor wheel. This housing not only protects the wheel but also directs the flow of air efficiently. The design of the housing is tailored to match the specific turbocharger model, optimizing air compression and minimizing turbulence, which directly influences the turbocharger’s performance.

Contribution to Turbocharger Kit

In a turbocharger kit, the 3528999 Compressor Housing plays a significant role by providing a robust and precise enclosure for the compressor components. This housing is engineered to withstand high pressures and temperatures, ensuring durability and reliability. Its integration into the kit is essential for maintaining the balance and efficiency of the entire turbocharger system.

Impact on Engine Performance

The effectiveness of the 3528999 Compressor Housing directly impacts engine performance. By ensuring optimal air compression, it contributes to increased engine power and efficiency. The housing’s design facilitates smooth airflow, reducing the risk of performance bottlenecks. This, in turn, allows the engine to operate more effectively, enhancing overall vehicle performance.

Conclusion

The 3528999 Compressor Housing is a vital component in the turbocharger system, designed to enhance engine performance through efficient airflow and pressure management. Its robust construction, compatibility with Cummins engines, and role in optimizing turbocharger performance make it an essential part for commercial truck applications. Regular maintenance and proper installation are key to ensuring its longevity and effectiveness.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.