This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

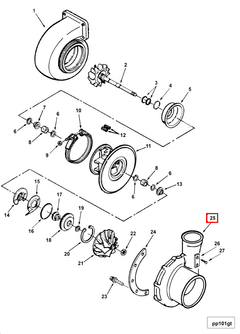

The Cummins 3529016 Compressor Housing is a vital component in the turbocharger system of heavy-duty trucks. Its purpose is to facilitate the efficient compression and delivery of air to the engine, thereby enhancing overall engine performance and efficiency.

Basic Concepts of Compressor Housing

A compressor housing is a fundamental part of the turbocharger system. It encases the compressor wheel, which spins at high speeds to compress incoming air before it enters the engine. This compressed air increases the oxygen available for combustion, which in turn boosts engine power and efficiency. The compressor housing plays a role in maintaining the integrity of the compressed air flow and ensuring that the air reaches the engine in optimal condition 1.

Purpose of the 3529016 Compressor Housing

The 3529016 Compressor Housing specifically serves to house and protect the compressor wheel within the turbocharger. It ensures that the compressed air is delivered efficiently to the engine’s intake system. By maintaining a sealed environment, it prevents air leaks and ensures that the compressed air reaches the engine with minimal loss of pressure, thereby supporting consistent engine performance 2.

Key Features

The 3529016 Compressor Housing is constructed from high-quality materials that offer durability and resistance to the high temperatures and pressures within the turbocharger system. Its design includes precise engineering to ensure a tight seal around the compressor wheel, minimizing air leakage. Additionally, it features robust mounting points to withstand the dynamic forces experienced during operation, contributing to its longevity and reliable performance.

Benefits

Using the 3529016 Compressor Housing offers several benefits. It contributes to improved engine efficiency by ensuring that the compressed air is delivered effectively to the engine. This results in enhanced performance, as the engine can combust fuel more efficiently. Additionally, the durable construction of the housing supports the reliability of the turbocharger system, reducing the likelihood of failures and extending the overall lifespan of the component.

Installation Process

Proper installation of the 3529016 Compressor Housing involves several steps. First, ensure that the engine is cool and the turbocharger system is depressurized. Disconnect any electrical connections and remove the old compressor housing, taking care to note the position of any gaskets or seals. Clean the mating surfaces thoroughly to ensure a proper seal. Install the new housing, ensuring that all gaskets and seals are correctly positioned. Reconnect any electrical connections and test the system for leaks before starting the engine.

Common Issues and Troubleshooting

Common issues with the 3529016 Compressor Housing may include air leaks, reduced efficiency, or physical damage. To troubleshoot these issues, inspect the housing for cracks or damage, check the seals and gaskets for wear, and ensure that all connections are secure. If air leaks are detected, replace any worn seals or gaskets. Regular inspection and maintenance can help prevent these issues.

Maintenance Tips

To ensure the longevity and optimal performance of the 3529016 Compressor Housing, regular maintenance is recommended. This includes inspecting the housing for signs of wear or damage, checking the seals and gaskets for integrity, and ensuring that all connections are tight. Additionally, keeping the turbocharger system clean and free of debris can help maintain efficient operation.

Performance Enhancements

The 3529016 Compressor Housing contributes to overall engine performance by ensuring efficient air compression and delivery. This can lead to potential improvements in fuel efficiency, as the engine can operate more effectively with a consistent supply of compressed air. Additionally, the enhanced airflow supports increased power output, making the engine more responsive and capable of handling demanding tasks.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions control technologies. With a strong reputation in the automotive industry, Cummins is known for its commitment to innovation, quality, and customer satisfaction. The company’s extensive product range and expertise in engine technology make it a trusted name in the heavy-duty truck market.

Cummins Compressor Housing Part 3529016 Compatibility

The Cummins Compressor Housing part number 3529016 is designed to fit seamlessly with several engine models, ensuring optimal performance and reliability. This part is integral to the engine’s air intake system, providing a durable and efficient housing for the compressor.

N14 MECHANICAL Engines

The N14 MECHANICAL engines benefit from the robust design of the 3529016 Compressor Housing. This part ensures that the engine’s air intake system operates efficiently, contributing to the overall performance and longevity of the engine.

NH/NT 855 Engines

For the NH/NT 855 engines, the 3529016 Compressor Housing is engineered to match the specific requirements of these models. Its precision fit and high-quality construction help maintain the integrity of the air intake system, ensuring consistent engine performance.

QSK38 CM850 MCRS Engines

The QSK38 CM850 MCRS engines also utilize the 3529016 Compressor Housing. This part is designed to integrate perfectly with the engine’s architecture, providing a reliable housing for the compressor that supports the engine’s demanding operational needs.

By ensuring a precise fit and high-quality construction, the Cummins Compressor Housing part number 3529016 is a critical component for maintaining the efficiency and reliability of these engines.

Role of Part 3529016 Compressor Housing in Engine Systems

The Compressor Housing (part 3529016) is a fundamental component in various engine systems, particularly those involving turbochargers and aftermarket turbocharger setups. It interfaces with several key components to ensure efficient engine performance.

Interaction with Turbocharger Components

-

Turbocharger and Aftermarket Turbocharger: The Compressor Housing is directly connected to the turbocharger, where it encases the compressor wheel. This housing is responsible for directing the flow of compressed air into the engine’s intake system. In aftermarket turbocharger setups, this housing may be upgraded for better airflow and efficiency.

-

Turbocharger Kit: When installing a turbocharger kit, the Compressor Housing plays a vital role in integrating the turbocharger with the engine. It ensures that the compressed air is delivered smoothly and effectively to the intake manifold.

Integration with Engine Components

-

Cylinder Head: The compressed air from the Compressor Housing is routed to the cylinder head, where it mixes with fuel before combustion. Proper sealing and alignment of the housing are essential to maintain optimal air-fuel ratios.

-

Injector and Injector Plumbing: The Compressor Housing works in tandem with the injector system. The increased air volume from the compressor requires precise fuel delivery, managed by the injectors and their plumbing, to maintain engine performance and prevent issues like detonation.

Compatibility with Performance Parts

-

EBM: Performance Parts and EBM: Turbocharger: For engines equipped with EBM performance parts, the Compressor Housing must be compatible to handle the increased airflow demands. This ensures that the turbocharger can operate efficiently within the parameters set by the performance modifications.

-

Cam Follower Housing and Camshaft: In engines with complex valvetrains, such as those with a camshaft right bank configuration, the Compressor Housing must be designed to accommodate the spatial requirements of these components. This ensures that there are no interferences and that the engine can operate smoothly.

Additional Considerations

-

Connecting Rod and Piston: The increased air pressure from the Compressor Housing affects the dynamics of the connecting rod and piston assembly. Engineers must ensure that these components can withstand the higher pressures and temperatures resulting from forced induction.

-

Dataplate: The dataplate on the engine provides essential information about the engine’s specifications and modifications. When upgrading or modifying the Compressor Housing, it’s important to update the dataplate to reflect these changes, ensuring that future maintenance and repairs are performed correctly.

Conclusion

In summary, the Compressor Housing (part 3529016) is a key component that interacts with various engine systems to enhance performance and efficiency. Its proper integration and compatibility with other components are essential for optimal engine operation.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.