This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3535757 Compressor Housing is a component designed to enhance the performance of turbocharger systems in commercial trucks. Its role is to facilitate efficient airflow within the turbocharger, which in turn contributes to improved engine performance. Understanding its function and significance can help fleet operators and technicians maintain and optimize engine efficiency.

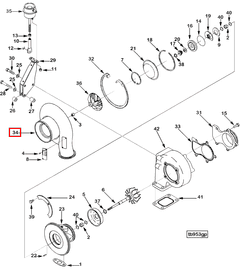

Basic Concepts of Compressor Housing

Compressor housings are integral to the operation of turbochargers. They encase the compressor wheel, which spins at high speeds to compress incoming air before it enters the engine. This compressed air increases the oxygen available for combustion, leading to enhanced engine efficiency and power output. The design and material of the compressor housing play a role in ensuring that this process is as effective as possible 1.

Purpose of the 3535757 Compressor Housing

The 3535757 Compressor Housing is specifically engineered to improve the airflow within a truck’s turbocharger system. By providing a robust and efficient pathway for air, it contributes to increased engine power and overall performance. Its design allows for optimal air compression, which is vital for maintaining engine efficiency under various operating conditions 2.

Key Features

The 3535757 Compressor Housing is constructed with a focus on durability and efficiency. It is made from high-quality materials that offer resistance to wear and corrosion. The housing’s design includes features that enhance its structural integrity and ensure smooth airflow. These characteristics contribute to its longevity and reliable performance in demanding environments 3.

Benefits

The advantages of using the 3535757 Compressor Housing include improved engine efficiency, increased power output, and enhanced durability. These benefits can lead to potential cost savings for fleet operators by reducing the need for frequent replacements and maintenance. Additionally, the housing’s efficient design contributes to better overall engine performance, which can be particularly beneficial in commercial truck applications.

Installation Process

Installing the 3535757 Compressor Housing requires careful attention to detail to ensure optimal performance. The process involves securing the housing to the turbocharger, ensuring all connections are tight and secure. Proper tools and procedures should be followed to avoid damage to the component or the turbocharger system. It is also important to verify that the housing is correctly aligned and that all seals are intact to prevent leaks.

Common Issues and Troubleshooting

Frequent problems with compressor housings can include leaks, cracks, and performance issues. These may arise from wear and tear, improper installation, or exposure to extreme conditions. Troubleshooting methods involve inspecting the housing for visible damage, checking for proper alignment and seal integrity, and ensuring that all connections are secure. Addressing these issues promptly can help maintain engine performance and prevent further damage.

Maintenance Tips

To ensure the long-term reliability and performance of the 3535757 Compressor Housing, regular maintenance is recommended. This includes inspecting the housing for signs of wear or damage, cleaning it to remove any debris that could obstruct airflow, and following recommended service intervals for more thorough checks. Proper maintenance can help extend the life of the component and maintain engine efficiency.

Compatibility and Application

The 3535757 Compressor Housing is designed for specific types of engines and truck models. It is important to verify compatibility to ensure optimal performance and integration with the turbocharger system. Application notes may provide additional guidance on installation and usage, helping to ensure that the housing functions as intended within the engine system.

Cummins Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its commitment to quality and innovation. With a diverse product range, Cummins has built a reputation for delivering reliable and high-performance engine components. The company’s focus on advancing technology and meeting the needs of its customers underscores its position as a leader in the industry.

Cummins Compressor Housing (Part 3535757) Compatibility

The Cummins Compressor Housing, identified by part number 3535757, is a critical component designed to fit seamlessly with various Cummins engine models. This part is engineered to ensure optimal performance and durability, making it a reliable choice for engine maintenance and repair.

Engine Compatibility

- 6B5.9 Series: The 3535757 Compressor Housing is specifically designed to fit within the 6B5.9 engine series. This engine series is known for its robust construction and efficiency, making it a popular choice in various industrial applications. The housing’s precise fit ensures that it integrates smoothly with the engine’s design, providing essential support and functionality.

Engineering and Design

The 3535757 Compressor Housing is crafted with high-quality materials to withstand the demanding conditions of engine operation. Its design focuses on durability and performance, ensuring that it can handle the pressures and temperatures typical of engine environments. This part is engineered to maintain the integrity of the engine’s air intake system, which is crucial for efficient combustion and overall engine performance.

Installation and Maintenance

Proper installation of the 3535757 Compressor Housing is essential to ensure that the engine operates at peak efficiency. Technicians should follow the manufacturer’s guidelines for installation to avoid any potential issues. Regular maintenance checks are also recommended to ensure that the housing remains in good condition and continues to provide reliable performance.

Application in Industrial Settings

In industrial settings, the 3535757 Compressor Housing is often used in applications where reliability and performance are critical. Its compatibility with the 6B5.9 engine series makes it a preferred choice for industries that require robust and efficient engine solutions. The housing’s design ensures that it can handle the rigors of continuous operation, making it suitable for a wide range of industrial applications.

Role of Part 3535757 Compressor Housing in Engine Systems

The Compressor Housing (Part 3535757) is an integral component in the operation of a Turbocharger and Turbocharger Kit. It is responsible for enclosing and directing the flow of compressed air from the compressor wheel to the engine’s intake system.

When integrated into a Turbocharger, the Compressor Housing works in tandem with the turbine housing to enhance engine performance. The housing ensures that the compressed air is delivered efficiently to the engine’s cylinders, allowing for better combustion and increased power output.

In a Turbocharger Kit, the Compressor Housing is often a key replacement or upgrade part. It is designed to fit precisely with the turbocharger’s compressor wheel, ensuring a secure and leak-free connection. This housing helps maintain the integrity of the compressed air path, reducing the risk of air leaks that could compromise engine efficiency.

The Compressor Housing also plays a role in thermal management. By containing the hot compressed air, it helps in dissipating heat away from the turbocharger’s sensitive components, contributing to the overall reliability and longevity of the system.

Conclusion

In summary, the Compressor Housing (Part 3535757) is essential for the effective functioning of turbochargers and turbocharger kits, ensuring efficient air delivery, maintaining system integrity, and aiding in thermal management. Its robust design and compatibility with specific engine models make it a reliable component for enhancing engine performance in commercial and industrial applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.