This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

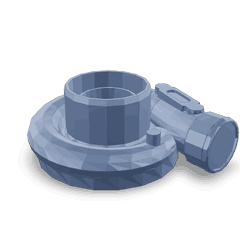

The Cummins 3535811 Compressor Housing is a component designed to enhance the performance of turbocharger systems in commercial trucks. It plays a role in optimizing engine performance by facilitating efficient air compression, which is vital for the operation of turbocharged engines. This housing is integral to maintaining the high standards of power and efficiency expected in heavy-duty truck applications 1.

Basic Concepts of Compressor Housing

Compressor housings are fundamental to the operation of turbochargers. They encase the compressor wheel, which compresses the intake air before it enters the engine. This compression increases the air density, allowing more oxygen to enter the combustion chamber. As a result, the engine can burn more fuel per cycle, leading to enhanced power output and efficiency. The design and material of the compressor housing are critical in ensuring that this process is both effective and reliable 4.

Purpose and Function of the 3535811 Compressor Housing

The 3535811 Compressor Housing is specifically engineered to house the compressor wheel within the turbocharger system of a truck’s engine. Its role involves directing and compressing the intake air, which is then fed into the engine’s combustion chambers. This increased air intake allows for more efficient combustion, contributing to enhanced engine performance and power output. The housing is designed to withstand the high pressures and temperatures associated with turbocharged engines, ensuring consistent performance under various operating conditions 2.

Key Features

The 3535811 Compressor Housing boasts several features that enhance its durability and efficiency. Constructed from high-quality materials, it is designed to resist corrosion and wear, ensuring longevity in demanding environments. The housing’s design includes precise engineering to optimize air flow and reduce turbulence, which contributes to more efficient compression. Additionally, it may feature unique attributes such as advanced sealing mechanisms to prevent air leaks, further enhancing performance 3.

Benefits of Using the 3535811 Compressor Housing

Incorporating the 3535811 Compressor Housing into a truck’s engine system offers several advantages. It contributes to improved engine performance by ensuring efficient air compression, which leads to increased power output. Furthermore, the enhanced air intake can result in better fuel efficiency, reducing operational costs. The housing’s robust construction and design also contribute to increased reliability, making it well-suited for the demanding conditions typical of commercial truck operations 1.

Installation and Compatibility

Proper installation of the 3535811 Compressor Housing is vital to ensure optimal performance and longevity. It is designed to be compatible with specific engine models and turbocharger systems, ensuring a precise fit and function. Installation procedures should follow manufacturer guidelines to maintain the integrity of the housing and the overall turbocharger system. Ensuring compatibility with the engine and turbocharger model is crucial for achieving the desired performance enhancements 2.

Maintenance and Troubleshooting

Routine maintenance of the 3535811 Compressor Housing is important for ensuring its longevity and efficiency. Regular inspections for signs of wear, corrosion, or damage can help identify potential issues before they lead to performance declines. Common maintenance practices include cleaning the housing to remove any debris that may affect air flow and checking for proper sealing to prevent air leaks. Troubleshooting tips may involve addressing unusual noises or performance drops, which could indicate issues with the compressor wheel or housing integrity 3.

Performance Enhancements

The 3535811 Compressor Housing contributes to overall engine performance enhancements by facilitating efficient air compression. This leads to increased horsepower and torque, improving the truck’s overall performance. Additionally, the enhanced air intake can result in improved fuel economy, offering cost savings over time. Real-world applications and testimonials from fleet operators highlight the housing’s effectiveness in demanding commercial truck operations, underscoring its value in enhancing engine performance 4.

Cummins Corporation Overview

Cummins Inc. is a renowned name in the automotive and heavy-duty truck industries, with a history of innovation, quality, and customer satisfaction. The company’s commitment to developing reliable and high-performance components is evident in its product lineup, including the 3535811 Compressor Housing. Cummins’ reputation for excellence is built on a foundation of rigorous testing, advanced engineering, and a dedication to meeting the needs of its customers in the commercial trucking sector 1.

Cummins Compressor Housing Part 3535811 Compatibility

The Cummins Compressor Housing part number 3535811 is designed to fit seamlessly with a range of Cummins engines, ensuring optimal performance and reliability. This part is integral to the engine’s air intake system, providing a durable and efficient housing for the compressor.

Engine Compatibility

4B3.9 and 6C8.3 Engines

The part 3535811 is specifically engineered to integrate with the 4B3.9 and 6C8.3 engines. These engines are known for their robust construction and are widely used in various applications, from industrial machinery to heavy-duty vehicles. The compressor housing ensures that the air intake system functions efficiently, maintaining the engine’s performance and longevity 2.

Grouping of Engines

The 4B3.9 and 6C8.3 engines share several common characteristics, making the compressor housing part 3535811 a versatile fit. Both engines benefit from the precise engineering of this part, which helps in maintaining the air-fuel mixture’s integrity and ensuring smooth operation 2.

Applications

The compatibility of the compressor housing with these engines makes it suitable for a variety of applications. Whether used in agricultural equipment, construction machinery, or transportation vehicles, this part ensures that the engine operates at peak efficiency. Its design allows for easy installation and maintenance, contributing to the overall reliability of the engine systems it supports 2.

Role of Part 3535811 Compressor Housing in Engine Systems

The Part 3535811 Compressor Housing is an essential component in the efficient operation of various engine systems, particularly when integrated with aftermarket turbochargers and turbocharger kits. Its primary function is to encase and protect the compressor wheel, which is a key element in the turbocharging process 4.

When paired with an Aftermarket Turbocharger, the Compressor Housing works in tandem with the turbine housing to facilitate the turbocharging process. The compressor wheel, housed within Part 3535811, compresses the intake air, which is then forced into the engine’s combustion chambers at a higher pressure. This increased air density allows for more fuel to be burned, resulting in enhanced engine performance and power output 4.

In conjunction with an Engine Installation Kit, the Compressor Housing ensures a secure and precise fit within the engine bay. This kit often includes necessary mounting brackets, gaskets, and hardware, which are essential for the proper installation and operation of the turbocharger system. The Compressor Housing must be correctly aligned and sealed to prevent air leaks, which can significantly impact engine efficiency and performance 2.

The Exhaust Manifold Kit also plays a significant role when integrated with the Compressor Housing. The exhaust manifold collects exhaust gases from the engine’s cylinders and directs them towards the turbine housing of the turbocharger. The efficient flow of exhaust gases is vital for spinning the turbine wheel, which in turn drives the compressor wheel housed within Part 3535811. A well-designed exhaust manifold ensures minimal backpressure, allowing the turbocharger to operate at optimal efficiency 4.

The Fuel Injection Pump and Fuel Pump Coupling are other components that interact indirectly with the Compressor Housing. As the Compressor Housing increases the air intake, the Fuel Injection Pump must deliver a corresponding increase in fuel to maintain the correct air-fuel ratio. The Fuel Pump Coupling ensures that the fuel pump operates smoothly and efficiently, providing the necessary fuel pressure and flow rate required by the engine under boosted conditions 3.

Lastly, within a comprehensive Turbocharger Kit, the Compressor Housing is a fundamental piece. This kit typically includes the turbocharger, intercooler, piping, and various sensors and control components. The Compressor Housing, as part of this kit, ensures that the compressed air is delivered to the engine in a controlled and efficient manner, contributing to the overall performance and reliability of the turbocharged engine system 4.

Conclusion

The Cummins 3535811 Compressor Housing is a critical component in the turbocharger systems of commercial trucks, designed to enhance engine performance through efficient air compression. Its robust construction, precise engineering, and compatibility with specific engine models make it a reliable choice for demanding applications. Proper installation, routine maintenance, and understanding its role within the engine system are essential for maximizing its benefits and ensuring long-term reliability.

-

Department of Energy Fundamentals Handbook, Department of Energy, 2015.

↩ ↩ ↩ -

Modern Diesel Technology Heavy Equipment Systems, Robert Huzij, Angelo Spano, Sean Bennett, Delmar Cengage Learning, 2014.

↩ ↩ ↩ ↩ ↩ ↩ -

SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety, R. Matthew Brach, SAE International, 2023.

↩ ↩ ↩ -

Advances in Engine and Powertrain Research and Technology, Tigran Parikyan Ed, Springer Nature, 2022.

↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.