This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

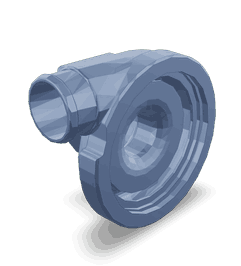

The Cummins 3536635 Compressor Housing is a component designed for use in heavy-duty trucks. It serves a significant role within the turbocharger system, contributing to the overall efficiency and performance of the engine. Understanding its function and importance can provide valuable insights into the operation of turbocharged diesel engines.

Basic Concepts of Compressor Housing

A compressor housing is a part of the turbocharger that encases the compressor wheel. Its function is to direct the flow of air into the engine, compressing it before it enters the combustion chamber. This compressed air allows for more fuel to be burned, which in turn increases the engine’s power output and efficiency. The compressor housing plays a role in maintaining the structural integrity of the turbocharger and ensuring that the air flow is optimized for performance 1.

Role of the 3536635 Compressor Housing in Truck Operation

This Cummins part is integral to the operation of a truck’s engine. It houses the compressor wheel, which spins at high speeds to compress the intake air. This compressed air is then delivered to the engine, where it mixes with fuel for combustion. The efficiency of this process directly impacts the engine’s power output and fuel economy. By ensuring that the air is properly compressed and delivered, the 3536635 Compressor Housing contributes to the overall performance of the truck.

Key Features of the 3536635 Compressor Housing

The 3536635 Compressor Housing is characterized by its robust material construction, typically made from durable alloys that can withstand high temperatures and pressures. Its design includes precise engineering to optimize air flow and reduce turbulence, which can enhance engine performance. Additionally, it may feature unique characteristics such as advanced coatings or heat treatment processes that further improve its durability and efficiency.

Benefits of Using the 3536635 Compressor Housing

Utilizing this part can lead to several benefits. These include improved engine performance due to optimized air compression, increased durability from its high-quality construction, and enhanced reliability under demanding operating conditions. The housing’s design also contributes to better fuel efficiency and reduced emissions, aligning with modern environmental standards.

Installation and Compatibility

Proper installation of the 3536635 Compressor Housing is vital to ensure it functions correctly within the turbocharger system. It is designed to be compatible with specific Cummins engine models, ensuring a precise fit and optimal performance. Installation procedures should follow manufacturer guidelines to maintain the integrity of the turbocharger system.

Maintenance and Troubleshooting

Regular maintenance of the 3536635 Compressor Housing is important to ensure its longevity and performance. This includes inspecting for signs of wear or damage, cleaning to remove any debris that could affect air flow, and checking for proper sealing to prevent leaks. Common issues may include cracks in the housing or damage to the compressor wheel, which can be identified through routine inspections and addressed promptly.

Performance Enhancements

The 3536635 Compressor Housing can contribute to performance enhancements in heavy-duty trucks. By optimizing the compression of intake air, it allows for more efficient combustion, which can result in increased horsepower and torque. This can lead to improved acceleration and overall driving performance, making it a valuable component for trucks that require high levels of power and efficiency.

Durability and Longevity

The durability and longevity of the 3536635 Compressor Housing are influenced by several factors, including the quality of materials used, the precision of its design, and the conditions under which it operates. Regular maintenance and proper installation can help maximize its service life. Additionally, operating the engine within recommended parameters can prevent undue stress on the compressor housing, contributing to its durability.

Cummins Corporation Overview

Cummins Corporation is a well-established entity in the automotive industry, with a strong reputation for producing high-quality diesel engines and components. Founded in the early 20th century, Cummins has a history of innovation and excellence in engine technology. Its commitment to quality and performance is evident in the design and manufacturing of components like the 3536635 Compressor Housing, which are engineered to meet the demanding requirements of heavy-duty applications.

Compatibility with Cummins Engines

The Compressor Housing part 3536635 is compatible with several Cummins engine models, including but not limited to:

- 6B5.9: This engine variant benefits from the robust design of the 3536635 Compressor Housing, which ensures optimal performance and longevity.

The part’s design allows for seamless integration with the engine’s architecture, ensuring that the compressor operates efficiently. This compatibility is crucial for maintaining the engine’s performance and reliability.

Grouping of Compatible Engines

The Compressor Housing part 3536635 is particularly suited for engines within the Cummins 6B series. This grouping includes engines that share similar design principles and operational requirements, making the part a versatile choice for multiple engine models.

By ensuring that the Compressor Housing fits well with these engines, Cummins maintains a high standard of quality and performance across its engine lineup. This compatibility is a testament to Cummins’ commitment to providing reliable and durable engine components.

Role of Part 3536635 Compressor Housing in Engine Systems

The 3536635 Compressor Housing is an integral component within the turbocharger and turbocharger kit systems. It is designed to encase and support the compressor wheel, which is responsible for compressing the intake air before it enters the engine’s combustion chambers.

When integrated into a turbocharger, the compressor housing works in tandem with the turbine housing. As the exhaust gases spin the turbine, the connected compressor wheel within the housing compresses the incoming air. This pressurized air is then delivered to the engine, enhancing combustion efficiency and power output.

In a turbocharger kit, the compressor housing is often a key replacement or upgrade part. It ensures that the turbocharger operates within optimal parameters, providing the necessary air compression to match the engine’s requirements. The housing must be precisely fitted to maintain the integrity of the air flow and prevent any leaks that could reduce efficiency.

The interaction between the compressor housing and other components such as the intercooler, intake manifold, and engine control unit (ECU) is vital. The pressurized air from the compressor housing is typically routed through the intercooler to reduce its temperature, increasing its density and further improving combustion. The intake manifold then distributes this cooled, pressurized air to the engine cylinders. The ECU monitors and adjusts the air-fuel ratio to ensure optimal performance and efficiency.

Conclusion

In summary, the 3536635 Compressor Housing plays a significant role in enhancing the performance of turbocharger and turbocharger kit systems by ensuring efficient air compression and delivery to the engine. Its robust construction, precise design, and compatibility with Cummins engines make it a critical component for maintaining and improving engine performance in heavy-duty applications.

-

Richards, Paul, and Jim Barker. Automotive Fuels Reference Book. SAE International, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.