This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 2 Cylinder Compressor Crankcase, identified by Part #3558679, is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This part is integral to the functioning of heavy-duty truck systems, particularly in the compressor subsystem. Cummins is recognized for its commitment to producing high-quality components that enhance the performance and reliability of vehicles 1.

Basic Concepts and Functionality

Compressor crankcases are foundational components in compressor systems, housing the moving parts of the compressor and contributing to the system’s overall efficiency. The 2 Cylinder design of this crankcase allows for a specific arrangement of cylinders that work in tandem to compress air, which is then used for various functions within the truck, such as powering air brakes and other pneumatic systems. This design integrates seamlessly into the broader compressor system, ensuring efficient operation and compatibility with the truck’s engine and other components 2.

Purpose and Operational Role

The 2 Cylinder Compressor Crankcase plays a significant role in the operation of a truck by providing a secure and efficient environment for the compressor’s moving parts. It contributes to the compressor system’s ability to generate compressed air, which is vital for the truck’s braking system, suspension, and other pneumatic components. The efficient operation of this crankcase directly influences the truck’s overall performance, ensuring that these systems function reliably under various conditions 3.

Key Features

The 2 Cylinder Compressor Crankcase is characterized by several key features that enhance its performance and durability. These include a robust material composition designed to withstand the pressures and temperatures of compressor operation, a design that facilitates efficient air compression, and unique attributes such as precise engineering to ensure compatibility and optimal performance within the truck’s compressor system.

Benefits

The advantages provided by the 2 Cylinder Compressor Crankcase include improved efficiency in air compression, enhanced reliability of the compressor system, and specific performance enhancements that contribute to the overall effectiveness of heavy-duty trucks. These benefits are particularly valuable in ensuring that the truck’s pneumatic systems operate smoothly and reliably, even under demanding conditions.

Installation and Integration

Proper installation of the 2 Cylinder Compressor Crankcase is crucial for ensuring its effective integration with the truck’s compressor system. This process involves several steps, including preparing the installation site, using the appropriate tools, and following a sequence of actions to securely mount the crankcase. Careful attention to these steps ensures that the crankcase functions as intended, contributing to the compressor system’s efficiency and reliability.

Maintenance and Troubleshooting

Routine maintenance practices are essential for ensuring the longevity and optimal performance of the 2 Cylinder Compressor Crankcase. These practices include regular inspections, cleaning, and lubrication of moving parts. Additionally, being aware of common issues that may arise, such as leaks or unusual noises, and knowing the suggested troubleshooting steps can help maintain the crankcase’s efficiency and prevent more serious problems.

Performance Enhancements

The 2 Cylinder Compressor Crankcase contributes to enhanced truck performance in several ways. It plays a role in improving fuel efficiency by ensuring that the compressor system operates efficiently. Additionally, it enhances compressor output, which is crucial for the reliable operation of the truck’s pneumatic systems. Overall, the crankcase’s design and functionality contribute to the system’s reliability and the truck’s performance.

Safety Considerations

When working with the 2 Cylinder Compressor Crankcase, it is important to observe several safety guidelines and precautions. These include proper handling to avoid damage to the component, following safety procedures during installation to prevent injuries, and adhering to maintenance safety practices to ensure the component’s longevity and the system’s reliability. These precautions are vital for the safe and effective operation of the compressor system.

Cummins Overview

Cummins is a reputable manufacturer in the automotive and heavy-duty truck industry, known for its commitment to producing high-quality components. The company’s reputation is built on a history of innovation, reliability, and customer satisfaction. Cummins’ dedication to excellence is evident in their wide range of products, which are designed to meet the demanding requirements of heavy-duty applications, ensuring that vehicles operate efficiently and reliably.

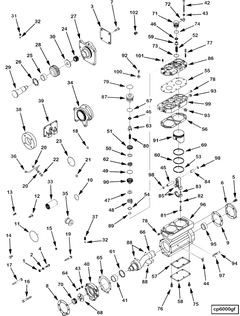

Understanding the Integration of Part 3558679 2 Cylinder Compressor Crankcase in Engine Systems

The 2 Cylinder Compressor Crankcase is an integral component in various engine systems, particularly those involving air compressors and compressors. Its role is to house and support the mechanical components that drive the compression process.

Interaction with Air Compressors

In air compressor systems, the crankcase serves as the foundation for the two-cylinder setup. It encapsulates the crankshaft, connecting rods, and pistons, which are essential for converting mechanical energy into compressed air. The crankcase ensures that these components operate in a sealed environment, maintaining the integrity of the compression process. It also facilitates the lubrication system, which is vital for reducing friction and wear on moving parts.

Role in Compressor Systems

For general compressor applications, the crankcase similarly supports the mechanical assembly that drives compression. It integrates with the compressor’s drive mechanism, whether it be an electric motor or an engine, to ensure smooth operation. The crankcase’s design allows for efficient heat dissipation, which is important for maintaining optimal performance and longevity of the compressor.

Ensuring Air Quality and System Efficiency

The seal provided by the crankcase is important for maintaining the quality of the compressed air. Any leaks or inefficiencies in the crankcase can lead to a drop in pressure and a reduction in the overall efficiency of the system. Therefore, the crankcase must be well-maintained and properly sealed to ensure that the compressor operates at peak performance.

Lubrication and Cooling

The crankcase also plays a significant role in the lubrication and cooling of the compressor’s internal components. It houses the oil sump, from which lubricant is circulated to critical moving parts. Effective lubrication reduces friction, minimizes wear, and helps in dissipating heat generated during operation.

Structural Integrity

From a structural standpoint, the crankcase provides the necessary support for the compressor’s cylinders, pistons, and crankshaft. Its robust construction ensures that these components remain aligned and operate efficiently under the stresses of compression.

Conclusion

In summary, the 2 Cylinder Compressor Crankcase is a fundamental component that ensures the reliable and efficient operation of air compressors and compressors. Its role in housing and supporting the mechanical components, facilitating lubrication, and maintaining structural integrity is essential for the overall performance of the engine system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.