This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3590162 Compressor Housing is designed to enhance the performance of turbocharger systems in commercial trucks. This part facilitates efficient airflow within the turbocharger, boosting engine performance and ensuring optimal engine operation in demanding commercial applications.

Basic Concepts of Compressor Housing

Compressor housings are integral to turbocharger systems, directing and managing the flow of air into the engine. By increasing airflow, these housings contribute to higher engine efficiency and power output. The design and construction of a compressor housing are essential for ensuring that air is compressed effectively before entering the engine, thereby enhancing overall performance 1.

Purpose of the 3590162 Compressor Housing

The 3590162 Compressor Housing aids in the compression of intake air, increasing its density and allowing more oxygen to enter the combustion chamber. This results in the engine producing more power with each combustion cycle, leading to improved overall performance and fuel efficiency 2.

Key Features

The 3590162 Compressor Housing is constructed from high-quality materials that provide structural integrity and resistance to high temperatures and pressures within the turbocharger system. Its design includes precise airflow channels and robust mounting points, contributing to its effectiveness and longevity.

Benefits

The advantages of the 3590162 Compressor Housing include improved engine performance, increased fuel efficiency, and enhanced reliability under demanding conditions. By ensuring efficient airflow and compression, this component helps the engine operate more effectively, leading to better overall vehicle performance and reduced fuel consumption 3.

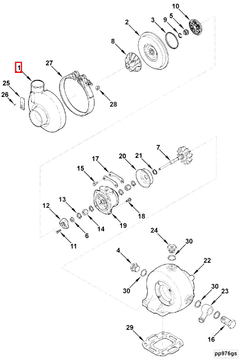

Installation Process

Proper installation of the 3590162 Compressor Housing involves ensuring the turbocharger and engine are clean and free of debris. Alignment considerations are crucial to maintain the integrity of the airflow path and prevent leaks. Following manufacturer guidelines during installation will help achieve optimal performance.

Common Issues and Troubleshooting

Typical problems associated with compressor housings include leaks, cracks, or a decline in performance. These issues can often be identified through visual inspection or performance diagnostics. Recommended troubleshooting steps include checking for proper alignment, inspecting seals and gaskets, and ensuring there is no damage to the housing itself. Solutions may involve repairs or replacement, depending on the severity of the issue.

Maintenance Tips

To ensure the longevity and consistent performance of the 3590162 Compressor Housing, regular maintenance is recommended. This includes periodic inspection for signs of wear or damage, cleaning to remove any buildup that could impede airflow, and following manufacturer guidelines for replacement intervals. Proper maintenance will help prevent issues and ensure the component continues to function effectively.

Compatibility and Application

The 3590162 Compressor Housing is designed for use in specific truck models and engine types, demonstrating its versatility and widespread application in the commercial trucking industry. Its compatibility ensures that it can be effectively integrated into various systems, providing reliable performance across different applications.

Cummins Overview

Cummins Inc. is a renowned manufacturer with a history of innovation and quality in the automotive and commercial vehicle industry. The company offers a wide range of products designed to meet the demanding needs of commercial applications. Cummins is known for its commitment to producing reliable and high-performance components, including the 3590162 Compressor Housing.

Role of the 3590162 Compressor Housing in Engine Systems

The 3590162 Compressor Housing is an integral component in various engine systems, particularly when integrated with aftermarket turbochargers and performance parts. Its primary function is to encase and direct the flow of compressed air from the turbocharger’s compressor wheel.

When paired with an aftermarket turbocharger, the compressor housing enhances the engine’s airflow efficiency. The housing is designed to withstand high pressures and temperatures, ensuring that the compressed air is delivered smoothly and consistently to the engine’s intake system. This results in improved engine performance and power output.

In conjunction with an engine oil cooler, the compressor housing contributes to maintaining optimal operating temperatures. The oil cooler helps to regulate the temperature of the engine oil, which in turn supports the turbocharger’s longevity and efficiency. The compressor housing must be robust enough to handle the thermal stresses induced by the high-speed rotation of the turbocharger.

When considering performance parts, the compressor housing is often upgraded to handle increased airflow demands. High-performance engines require more air to burn fuel efficiently, and a well-designed compressor housing can significantly contribute to this need. It ensures that the air entering the engine is not only compressed but also evenly distributed, which is essential for consistent engine performance.

In a turbocharger kit, the compressor housing is a key element that ensures the turbocharger functions as intended. It works in harmony with the turbine housing, intercooler, and other components to deliver a balanced and efficient forced induction system. The housing’s design directly impacts the turbocharger’s efficiency, backpressure, and overall performance.

Conclusion

The 3590162 Compressor Housing plays a vital role in enhancing the performance and efficiency of turbocharger systems in commercial trucks. Its design and construction ensure efficient airflow and compression, leading to improved engine performance, increased fuel efficiency, and enhanced reliability under demanding conditions. Proper installation, maintenance, and understanding of its role in engine systems are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.