This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3590224 Compressor Housing is a component designed to enhance the performance of turbocharger systems in commercial trucks. Its role is to facilitate efficient air compression, which is vital for optimizing engine performance. By improving the air intake process, this compressor housing contributes to increased engine power and overall efficiency in heavy-duty applications 1.

Basic Concepts of Compressor Housing

A compressor housing is a part of a turbocharger, encapsulating the compressor wheel and directing the flow of air. Its function is to compress the incoming air before it enters the engine, thereby increasing the air density. This compressed air mixes with fuel more effectively, leading to more complete combustion and enhanced engine efficiency. The principles of turbocharging rely on the compressor housing to maintain the integrity and efficiency of the air compression process 3.

Purpose of the 3590224 Compressor Housing

The 3590224 Compressor Housing is specifically engineered to play a role in the turbocharger system by increasing the volume of air that enters the engine. This increased air intake allows for more fuel to be burned, which in turn boosts engine power. The housing is designed to withstand high pressures and temperatures, ensuring reliable performance under demanding conditions typical of commercial truck operations 4.

Key Features

The 3590224 Compressor Housing boasts several key features that enhance its performance and durability. It is constructed from high-quality materials that resist corrosion and wear. The design includes precise engineering to ensure optimal airflow and minimal turbulence. Additionally, it features robust mounting points and seals to maintain a secure fit and prevent leaks, contributing to its longevity and effectiveness 2.

Benefits of Using the 3590224 Compressor Housing

Incorporating the 3590224 Compressor Housing into a truck’s engine system offers several advantages. It contributes to improved engine efficiency by ensuring a consistent and high-pressure air supply. This results in increased power output, allowing the engine to perform more effectively under load. Furthermore, the durable construction of the housing enhances its longevity, reducing the need for frequent replacements and maintenance 1.

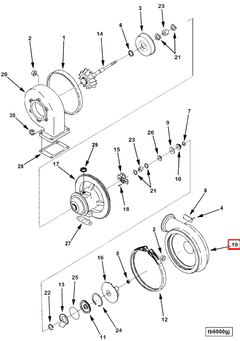

Installation Process

Installing the 3590224 Compressor Housing involves several steps to ensure proper fit and function. Begin by disconnecting the battery to prevent any electrical issues. Remove the old compressor housing, taking care to note the position of any gaskets or seals. Clean the mounting surface thoroughly to ensure a proper seal. Position the new housing and secure it with the appropriate fasteners. Reconnect any hoses or wiring, and finally, reconnect the battery. Tools required may include wrenches, sockets, and possibly a torque wrench to ensure proper tightening of fasteners 2.

Troubleshooting Common Issues

Common issues with compressor housings include leaks, cracks, and performance declines. Leaks can often be identified by a hissing sound or a drop in engine performance. Inspecting the housing for cracks or damaged seals can help pinpoint the source of the leak. Performance declines may indicate a buildup of debris within the housing, requiring a thorough cleaning. Regular inspections and maintenance can help prevent these issues 3.

Maintenance Tips

To ensure the longevity and optimal performance of the 3590224 Compressor Housing, regular maintenance is recommended. This includes periodic inspections for signs of wear or damage, such as cracks or leaks. Cleaning the housing to remove any buildup of dirt or debris is also important. Additionally, ensuring that all seals and gaskets are in good condition and properly seated will help maintain a secure and efficient system 4.

Compatibility and Applications

The 3590224 Compressor Housing is designed to be compatible with a range of engines and truck models. Its applicability extends across different makes and models of commercial trucks, providing a versatile solution for enhancing engine performance. Ensuring compatibility with specific engine types and turbocharger models is important for optimal performance and integration 1.

Cummins Corporation Overview

Cummins Inc. is a renowned manufacturer in the automotive industry, known for its commitment to innovation and quality. With a history of producing reliable and high-performance engine components, Cummins has established a strong reputation. The company’s product range includes a variety of engine parts and systems, designed to meet the demanding requirements of commercial and industrial applications. Cummins’ dedication to advancing technology and maintaining high standards in manufacturing underscores its position as a leader in the industry 2.

Role of Compressor Housing in Engine Systems

The compressor housing (part 3590224) is an integral component in the operation of various engine systems, particularly when integrated with aftermarket turbochargers and turbocharger kits. Its primary function is to encase and support the compressor wheel, which is responsible for compressing the intake air before it enters the engine’s combustion chambers.

When paired with an aftermarket turbocharger, the compressor housing plays a significant role in enhancing the engine’s performance. The housing is designed to withstand high pressures and temperatures, ensuring that the compressed air is delivered efficiently to the cylinder head. This increased air volume allows for more fuel to be burned, resulting in greater power output and improved engine efficiency 3.

In the context of a turbocharger kit, the compressor housing works in conjunction with other components such as the connecting rod and performance parts. The compressed air from the housing increases the charge density in the cylinders, which, when combined with the precise movement of the connecting rod, leads to more forceful combustion events. This synergy between the compressor housing and other engine components is essential for achieving the desired performance gains 4.

Conclusion

The 3590224 Compressor Housing by Cummins is a vital component in enhancing the performance and efficiency of turbocharger systems in commercial trucks. Its robust design, compatibility with various engine models, and the role it plays in the air compression process make it an essential part of modern engine systems. Regular maintenance and proper installation are key to ensuring its longevity and optimal performance.

-

Robinson, A., & Livesey, A. (2006). The Repair of Vehicle Bodies Fifth Edition. Elsevier.

↩ ↩ ↩ -

Thompson, R. (2019). Automotive Maintenance: Light Repair. Cengage Learning.

↩ ↩ ↩ -

Miedema, S. A., & Lu, Z. (2010). The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema.

↩ ↩ ↩ -

Drozdziel, P. (2023). The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.