This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3594371 Compressor Housing is a critical component within the turbocharger system of heavy-duty trucks. It enhances engine performance and efficiency by compressing intake air, which is then delivered to the engine cylinders. This part is essential for the turbocharger’s functionality, contributing to the truck’s power output and fuel efficiency.

Basic Concepts of Compressor Housing

Compressor housings are designed to house the compressor wheel within the turbocharger. Their primary function is to direct and manage the flow of intake air as it is compressed by the compressor wheel. The compressor housing works in conjunction with the turbine housing, which houses the turbine wheel. Together, they create a system that uses exhaust gases to spin the turbine wheel, which in turn drives the compressor wheel. Maintaining optimal airflow and pressure within the compressor housing is vital for efficient turbocharger operation 1.

Purpose of the 3594371 Compressor Housing

The 3594371 Compressor Housing is specifically engineered to enhance the operation of a truck’s engine. It contributes to increased airflow by efficiently compressing the intake air before it enters the engine cylinders. This increased airflow allows for more fuel to be burned, resulting in improved engine efficiency and enhanced overall performance. The housing is designed to manage pressure effectively, ensuring that the compressed air is delivered at the right pressure for optimal combustion 2.

Key Features

The Cummins 3594371 Compressor Housing is characterized by several notable features. It is constructed from durable materials that can withstand the high pressures and temperatures within the turbocharger system. The housing is precisely engineered to ensure efficient airflow and pressure management. Design elements such as smooth internal surfaces and optimized geometry contribute to reduced turbulence and improved airflow, enhancing the performance of the turbocharger 3.

Benefits

The advantages provided by the 3594371 Compressor Housing include improved engine performance, increased fuel efficiency, and enhanced durability and reliability of the turbocharger system. By ensuring efficient compression and delivery of intake air, the housing contributes to more powerful and efficient engine operation. Its robust construction and precise engineering also contribute to the longevity and reliability of the turbocharger system.

Installation and Compatibility

Proper installation of the 3594371 Compressor Housing is crucial for ensuring correct fitment and integration with the truck’s turbocharger system. It is designed to be compatible with various Cummins engine models, ensuring seamless integration and optimal performance. Following the manufacturer’s guidelines for installation will help maintain the integrity and efficiency of the turbocharger system.

Troubleshooting and Maintenance

Regular maintenance and troubleshooting are important for ensuring the optimal performance and longevity of the 3594371 Compressor Housing. Common issues such as leaks, cracks, or inefficient airflow can be identified through routine inspections. Maintenance practices such as cleaning the housing and inspecting for wear or damage will help prevent issues and ensure continued efficient operation.

Performance Enhancements

There are potential upgrades or modifications that can be made to the 3594371 Compressor Housing to further enhance engine performance. These may include the use of high-flow compressor wheels or advanced materials that can withstand higher pressures and temperatures. Such enhancements can contribute to increased airflow and improved turbocharger efficiency, resulting in enhanced engine performance.

Cummins Overview

Cummins Inc. is a well-established company with a strong reputation in the automotive industry. Known for its commitment to producing high-quality engine components and systems, Cummins has a history of innovation and excellence. The company’s dedication to quality and performance is evident in its range of engine components, including the 3594371 Compressor Housing.

Cummins Engine Compatibility with Part 3594371

The Cummins part 3594371, a Compressor Housing, is designed to fit seamlessly within a range of Cummins engines. This part is integral to the engine’s operation, ensuring efficient air compression and delivery to the combustion chamber. Below is a detailed breakdown of the compatibility of this part with the specified engines:

QSK19G and QSK38 Series

- QSK19G: The Compressor Housing part 3594371 is specifically engineered to fit the QSK19G engine. This engine is known for its robust performance and reliability, making the part an essential component in maintaining its operational efficiency.

- QSK38 CM2150 MCRS and QSK38 CM850 MCRS: Both these variants of the QSK38 engine are compatible with the Compressor Housing part 3594371. The part’s design ensures it fits perfectly within the engine’s architecture, facilitating optimal air compression and contributing to the engine’s overall performance.

QSK60 Series

- QSK60 CM500 and QSK60 CM850 MCRS: The Compressor Housing part 3594371 is also suitable for the QSK60 series engines. These engines are designed for high-performance applications, and the part’s precision engineering ensures it integrates smoothly, enhancing the engine’s efficiency and reliability.

Each of these engines relies on the Compressor Housing part 3594371 to maintain its performance standards. The part’s compatibility across different engine models underscores its versatility and importance in the Cummins engine lineup.

Role of Part 3594371 Compressor Housing in Engine Systems

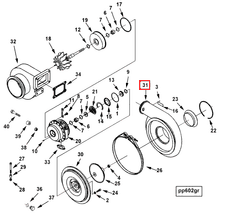

In the context of aftermarket turbochargers and turbocharger kits, the compressor housing (part 3594371) is an integral component that facilitates efficient air compression. When integrated into a turbocharger system, this housing encases the compressor wheel, which is driven by the turbine wheel via the shared shaft.

As the exhaust gases spin the turbine wheel, the connected compressor wheel draws in ambient air and compresses it within the housing. The compressed air is then directed through the intercooler, where it is cooled before entering the engine’s intake manifold. This process significantly enhances the engine’s power output by providing a denser air charge for combustion.

The compressor housing must be precisely matched with the turbocharger to ensure optimal performance. It works in conjunction with other components such as the turbocharger’s center housing, which houses the turbine wheel and the shared shaft. The efficiency of the compressor housing directly influences the overall performance of the turbocharger kit, affecting both power delivery and thermal efficiency.

Conclusion

The Cummins 3594371 Compressor Housing is a vital component in the turbocharger system of heavy-duty trucks. Its role in enhancing engine performance, ensuring efficient air compression, and contributing to the overall efficiency and reliability of the turbocharger system cannot be overstated. Proper installation, regular maintenance, and potential performance enhancements can further optimize its functionality, making it an indispensable part of the Cummins engine lineup.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.