This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

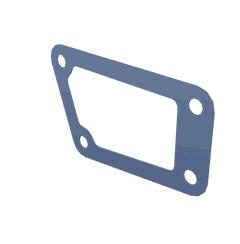

The Cummins 123146 Connection Gasket is a specialized component designed for use in heavy-duty truck operations. Its primary role is to ensure a secure and reliable seal between various engine components, contributing to the overall efficiency and reliability of the truck’s engine system.

Basic Concepts of Connection Gaskets

Connection gaskets are sealing elements used in mechanical systems to prevent leaks between mating surfaces. They play a vital role in maintaining the integrity of connections in engines and other machinery by filling gaps and compensating for surface imperfections. In engines, gaskets are essential for sealing combustion chambers, oil passages, and coolant pathways, ensuring that fluids and gases remain contained within their designated paths 1.

Purpose of the 123146 Connection Gasket

The Cummins 123146 Connection Gasket is specifically engineered to facilitate a secure seal in the engine or other systems it is part of. It ensures that fluids and gases are properly contained, which is fundamental for the engine’s performance and longevity. By maintaining the integrity of these seals, the gasket contributes to the engine’s operational efficiency and reliability 2.

Key Features

The Cummins 123146 Connection Gasket boasts several key features that enhance its performance and durability. These include a robust material composition designed to withstand high temperatures and pressures, a precise design that ensures a perfect fit, and unique characteristics that improve its sealing capabilities. These features collectively contribute to the gasket’s ability to perform reliably under demanding conditions 3.

Benefits

The advantages provided by the Cummins 123146 Connection Gasket are significant. It offers improved seal integrity, which is crucial for preventing leaks and ensuring that the engine operates efficiently. Its resistance to high temperatures and pressures makes it suitable for heavy-duty applications, and its design contributes to overall engine efficiency and reliability by maintaining proper seals 4.

Installation Considerations

Proper installation of the Cummins 123146 Connection Gasket is critical for its effectiveness. Guidelines and best practices include preparing mating surfaces to ensure they are clean and free of debris, adhering to torque specifications to avoid over-tightening or under-tightening, and using any special tools or procedures as recommended by the manufacturer. Careful attention to these details during installation helps ensure the gasket performs as intended .

Troubleshooting Common Issues

Common problems associated with connection gaskets, such as leaks or failures, can often be traced back to installation issues or environmental factors. Troubleshooting steps may include inspecting the gasket and mating surfaces for damage, ensuring proper torque was applied during installation, and checking for any signs of wear or degradation that may indicate the need for replacement .

Maintenance Tips

Regular maintenance of the Cummins 123146 Connection Gasket is important for its longevity and performance. This includes inspecting the gasket at recommended intervals for signs of wear or damage, and replacing it as necessary to prevent leaks and maintain engine efficiency. Adhering to these maintenance practices helps ensure the gasket continues to perform reliably over time .

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history and a broad product range, Cummins is renowned for its quality and reliability in the commercial truck industry. The company’s commitment to innovation and excellence is reflected in its products, including the Cummins 123146 Connection Gasket, which is designed to meet the demanding requirements of heavy-duty truck operations .

Role of Part 123146 Connection Gasket in Engine Systems

The part 123146 Connection Gasket is an essential component in various engine systems, ensuring the integrity and efficiency of the engine’s operation. This gasket is specifically designed to create a seal between different engine components, preventing leaks and maintaining proper pressure within the system.

Integration with Kit Spares

In a kit spares setup, the part 123146 Connection Gasket is often included to replace worn or damaged gaskets. Its role is to ensure that all connections within the spares kit are sealed correctly, which is vital for the kit’s overall functionality. Whether it’s sealing connections in the intake manifold or exhaust system, this gasket helps maintain the engine’s performance and longevity.

Function within the Kit

When part of a comprehensive kit, the Connection Gasket works in tandem with other gaskets and seals to provide a complete sealing solution. This ensures that all critical junctions within the engine are adequately sealed, reducing the risk of coolant, oil, or air leaks. The gasket’s precise fit and material properties are tailored to withstand the high temperatures and pressures typical in engine environments.

Role in PDC (Powertrain Control Module) Systems

In systems involving the Powertrain Control Module (PDC), the Connection Gasket plays a supportive role by ensuring that all fluid and air pathways are sealed. This is particularly important in maintaining the accuracy of sensor readings and the overall efficiency of the powertrain. A well-sealed system allows the PDC to operate optimally, making real-time adjustments based on precise data.

Importance in Lower Engine Gasket Kit

Within a lower engine gasket kit, the part 123146 Connection Gasket is used to seal connections between the lower engine components, such as the oil pan, valve covers, and timing chain covers. Its role is to prevent oil leaks, which can lead to decreased lubrication and potential engine damage. The gasket’s durability and sealing capabilities are essential for the lower engine’s reliable operation.

Contribution to Overhaul Gasket Set

In an overhaul gasket set, the Connection Gasket is a key component that ensures all major and minor connections within the engine are sealed. This includes sealing the cylinder head, intake manifold, and exhaust manifold. The gasket’s ability to withstand thermal cycling and mechanical stress is vital for the success of an engine overhaul, ensuring that the engine operates efficiently post-overhaul.

Conclusion

The Cummins 123146 Connection Gasket plays a critical role in ensuring the efficiency and reliability of heavy-duty truck engines. Its design and features are tailored to withstand the demanding conditions of engine operations, providing a secure seal that prevents leaks and maintains proper pressure within the system. Proper installation, regular maintenance, and understanding its role within various engine systems are essential for maximizing the performance and longevity of this Cummins part.

-

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩ -

Martyr, A.J. (2007). Engine Testing: Theory and Practice: Third Edition. SAE International.

↩ -

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for QSF2.8 CM2880 F131, Bulletin Number 5411490.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.