125549

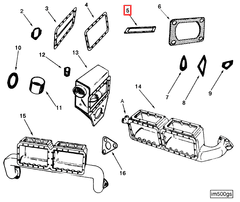

Connection Gasket

Cummins®

AVAILABLE

2 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 125549 Connection Gasket, manufactured by Cummins, is a component designed to facilitate the sealing process in commercial trucks. This gasket plays a role in maintaining the integrity of connections within the engine system, ensuring optimal performance and efficiency. Cummins, a well-established name in the industry, produces this gasket as part of its range of high-quality automotive components.

Basic Concepts of Connection Gaskets

Connection gaskets are sealing elements used in mechanical systems to prevent leaks between mating surfaces. They are placed between two or more parts that need to be sealed, such as flanges or pipe connections. In engines and other machinery, connection gaskets contribute to the sealing process by filling the gaps between surfaces, thereby preventing the escape of fluids or gases. This ensures that the system operates efficiently and safely 1.

Purpose of the 125549 Connection Gasket

This Cummins part is specifically designed to play a role in the sealing process within a truck’s engine or other components. It is positioned between surfaces that require a seal, such as between the engine block and cylinder head, or within the exhaust system. By providing a tight seal, this gasket helps maintain the pressure and integrity of the system, contributing to the overall performance and longevity of the truck.

Key Features

The 125549 boasts several key features that enhance its performance. It is composed of materials that offer excellent resistance to heat, pressure, and chemical exposure. The design of the gasket includes precise dimensions and surface finishes that ensure a secure fit and effective sealing. Additionally, it may incorporate unique characteristics such as multi-layered construction or reinforced edges to further improve its durability and sealing capabilities.

Benefits

Using the 125549 offers several advantages. It provides improved sealing efficiency, which helps maintain system pressure and prevent leaks. The gasket’s durable construction ensures long-lasting performance, reducing the need for frequent replacements. Additionally, its design may contribute to cost-effectiveness by offering reliable performance and reducing the risk of system failures that could lead to more extensive repairs.

Installation Process

Proper installation of the 125549 is crucial for ensuring a secure fit and effective sealing. The process involves several steps: first, prepare the mating surfaces by cleaning them thoroughly to remove any debris or old gasket material. Next, position the gasket correctly between the surfaces, ensuring it is aligned with any grooves or features designed to hold it in place. Use the appropriate tools to tighten the connection gradually, avoiding over-tightening which could damage the gasket or the surfaces. Following these steps will help achieve a secure and effective seal 2.

Maintenance and Troubleshooting

Regular maintenance of the 125549 involves inspecting it for signs of wear or damage during routine engine checks. Common issues that may arise include leaks due to gasket failure or improper installation. Troubleshooting tips include checking the mating surfaces for cleanliness and proper alignment, ensuring the gasket is not over-compressed, and verifying that the connection is tightened to the manufacturer’s specifications. Addressing these issues promptly can help maintain the gasket’s effectiveness and prolong its service life.

Compatibility and Applications

The 125549 is designed for use in specific types of trucks and engines. It is commonly applied in models or series where precise sealing is required to maintain system performance. Ensuring compatibility with the intended application is important for achieving optimal results and preventing potential issues.

Performance in Various Conditions

The 125549 is engineered to perform under a range of operating conditions. It can withstand extreme temperatures, high pressure, and varying load conditions, making it suitable for use in demanding environments. Its material composition and design attributes contribute to its ability to maintain an effective seal, even when subjected to challenging conditions.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of high-quality engine and component products. With a history of innovation and excellence, Cummins has established a strong reputation for producing reliable and efficient solutions for the automotive and heavy-duty truck sectors. The company’s commitment to quality and performance is reflected in its product lineup, including the 125549 3.

Role of Part 125549 Connection Gasket in Engine Systems

The part 125549 Connection Gasket is an essential component in various engine systems, ensuring the integrity and efficiency of the engine’s operation. This gasket is specifically designed to create a seal between different engine components, preventing leaks and maintaining proper pressure within the system.

In the Kit Spares, the Connection Gasket is used to replace worn-out or damaged gaskets, ensuring that the engine maintains its performance standards. It is often included in maintenance kits to facilitate easy replacement and to ensure that the engine continues to operate smoothly without any leaks.

Within the Single Head Gasket Set, the Connection Gasket plays a significant role in sealing the connection between the cylinder head and the engine block. This seal is vital for preventing coolant and oil from mixing, as well as for maintaining compression within the cylinders. The gasket ensures that the combustion process is efficient and that the engine operates within its designed parameters.

In the Upper Engine Gasket Kit, the Connection Gasket is utilized to seal various upper engine components, such as the intake manifold, exhaust manifold, and valve covers. This sealing is essential for maintaining the vacuum integrity of the intake system, ensuring efficient fuel delivery, and preventing exhaust gases from escaping prematurely. Additionally, it helps in keeping contaminants out of the engine, thus prolonging the lifespan of the components.

Similarly, in the Upper Engine Gasket Set, the Connection Gasket is employed to ensure that all upper engine components are properly sealed. This includes sealing the connections between the cylinder head, intake manifold, and other upper engine parts. The gasket’s role here is to maintain the engine’s overall efficiency by preventing any loss of pressure or introduction of unwanted elements into the combustion chambers.

Overall, the part 125549 Connection Gasket is a fundamental component in maintaining the seals and pressures necessary for the efficient operation of engine systems. Its proper installation and maintenance are key to ensuring the longevity and performance of the engine.

Conclusion

The 125549 Connection Gasket by Cummins is a critical component in the maintenance and efficiency of commercial truck engines. Its design and material composition ensure it can withstand various operating conditions, providing a reliable seal that prevents leaks and maintains system pressure. Proper installation and regular maintenance are essential to maximize its performance and longevity. Cummins’ reputation for quality and innovation is evident in this part, making it a valuable asset in engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.