This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Connection Gasket 194012, manufactured by Cummins, is a component designed to enhance the operational efficiency of commercial trucks. Cummins, a well-established name in the automotive industry, produces a range of parts that contribute to the reliability and performance of heavy-duty vehicles. This part is significant in maintaining the integrity of various systems within commercial trucks, ensuring they operate smoothly and efficiently.

Basic Concepts of Connection Gaskets

Connection gaskets are sealing components used in mechanical systems to prevent leaks and maintain pressure within various components. They are placed between two or more mating surfaces to create a seal. In the context of commercial trucks, these gaskets play a role in ensuring that fluids and gases remain contained within their designated pathways, thereby supporting the efficient operation of the vehicle’s systems 1.

Purpose of the 194012 Connection Gasket

This Cummins part is specifically designed to fit within the systems of commercial trucks manufactured by Cummins. It is positioned at critical junctions where sealing is required to prevent leaks and maintain system pressure. This gasket interfaces with various components, ensuring that the connections remain secure and the systems function as intended.

Key Features

The 194012 Connection Gasket is engineered with specific design and material characteristics to ensure durability and performance. It is made from materials that offer resistance to various environmental factors, such as temperature fluctuations and chemical exposure. This gasket is compatible with other components within the system, ensuring a secure and reliable fit.

Benefits

Using the 194012 Connection Gasket provides several advantages. It contributes to improved system efficiency by ensuring that connections remain sealed, reducing the likelihood of leaks. This results in reduced maintenance needs, as the gasket is designed to withstand the rigors of commercial truck operations. Additionally, the gasket enhances the reliability of the truck’s systems, supporting consistent performance 2.

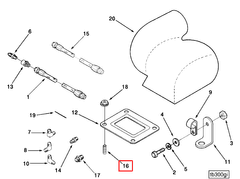

Installation Process

Proper installation of the 194012 Connection Gasket is crucial for its effective function. The process involves several steps to ensure a secure fit. Preparatory steps include cleaning the mating surfaces to remove any debris or old gasket material. The required tools may include a gasket scraper, a torque wrench, and appropriate fasteners. Best practices for installation include applying a light coating of lubricant to the gasket’s surface to facilitate placement and ensure an even seal.

Troubleshooting Common Issues

Typical problems associated with connection gaskets include leaks or failures. These issues can often be diagnosed by inspecting the gasket for signs of wear, damage, or improper installation. Suggested methods for resolving these issues include replacing the gasket if it is damaged, ensuring proper torque on fasteners, and verifying that the mating surfaces are clean and free of debris.

Maintenance Tips

Regular maintenance practices can prolong the lifespan of the 194012 Connection Gasket. Inspection routines should include checking for signs of wear or damage during routine maintenance intervals. Replacement guidelines suggest that the gasket should be inspected and, if necessary, replaced according to the manufacturer’s recommendations or when signs of degradation are observed.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a reputation for quality and innovation within the commercial truck industry. The company’s product range includes engines, powertrain, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicle operations.

Cummins Connection Gasket 194012 Compatibility

The Cummins Connection Gasket part number 194012 is designed to ensure a secure and leak-proof connection between various components in the engine system. This gasket is critical in maintaining the integrity of the engine by preventing fluid and gas leaks at the connection points. Below is a detailed description of how this gasket fits with the Cummins V903 engine.

Cummins V903 Engine

The Cummins V903 engine is a robust and reliable power unit, often utilized in heavy-duty applications. The Connection Gasket 194012 is integral to the V903 engine’s operation, providing a crucial seal in several key areas. This gasket is typically used in the following applications within the V903 engine:

- Cylinder Head to Block Connection: Ensuring that the cylinder head is securely fastened to the engine block, preventing coolant or oil leaks.

- Oil Pan to Engine Block: Creating a tight seal between the oil pan and the engine block to maintain proper oil levels and prevent oil leaks.

- Turbocharger to Exhaust Manifold: Providing a seal between the turbocharger and the exhaust manifold, which is essential for maintaining boost pressure and preventing exhaust leaks.

The gasket’s material is specifically engineered to withstand the high temperatures and pressures found in the engine environment, ensuring long-lasting performance and reliability. Its precision-engineered design guarantees a perfect fit, reducing the risk of leaks and maintaining engine efficiency.

By using the Cummins Connection Gasket 194012, engine operators can be confident in the durability and performance of their V903 engine, knowing that critical connection points are sealed effectively.

Role of Part 194012 Connection Gasket in Engine Systems

The part 194012 Connection Gasket is an essential component in ensuring the integrity and efficiency of various engine systems. Its primary function is to create a secure seal between different components, preventing leaks and maintaining system pressure. Here’s how it integrates with several key engine systems:

Gear Oil Cooler and Marine Gear Oil Cooler

In both the gear oil cooler and marine gear oil cooler systems, the Connection Gasket ensures a tight seal between the cooler and its mounting surfaces. This seal is vital for maintaining the flow of oil without any leakage, which is essential for the lubrication and cooling of gear components.

Heat Exchanger and Heat Exchanger Kit

When installed in a heat exchanger or as part of a heat exchanger kit, the Connection Gasket plays a role in sealing the interfaces between the heat exchanger core and its housing. This ensures that the coolant or other fluids pass through the system efficiently without any loss, maximizing heat transfer and system performance.

Radiator

In radiator applications, the Connection Gasket is used to seal the connections between the radiator tank and the core. This prevents coolant leakage and ensures that the cooling system operates at optimal efficiency, maintaining engine temperature within safe limits.

Sea Water Pipe and Sea Water Piping

For marine applications involving sea water pipes and piping, the Connection Gasket is employed to seal the joints where sea water enters and exits the engine cooling system. This is important for preventing seawater from mixing with the engine’s coolant, which could lead to corrosion and system failure.

Turbocharger Mounting

In turbocharger systems, the Connection Gasket is used to seal the connection points between the turbocharger and the engine. This ensures that the pressurized air from the turbocharger is delivered efficiently to the engine’s intake system without any loss of pressure, enhancing engine performance and efficiency.

Lower Engine Gasket Set

As part of a lower engine gasket set, the Connection Gasket is utilized to seal various lower engine components, such as the oil pan, valve covers, and timing chain covers. This prevents oil leaks and maintains the engine’s lubrication system integrity.

Conclusion

In summary, the 194012 Connection Gasket is a versatile component that enhances the functionality and reliability of various engine systems by ensuring secure seals and preventing fluid leaks. Its role in maintaining system integrity and efficiency makes it a critical part in the operation of commercial trucks and heavy-duty engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.